This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

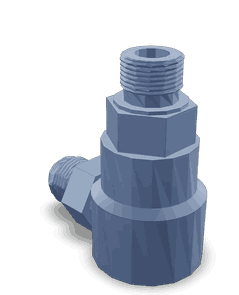

The Cummins 4371676 Check Valve is a component designed for use in commercial truck systems. Its purpose is to regulate the flow of fluids, ensuring that they move in a single direction within the system. This valve plays a role in maintaining the efficiency and reliability of the truck’s operations by preventing backflow, which can lead to system inefficiencies or damage 2.

Basic Concepts of Check Valves

A check valve, also known as a non-return valve, is a mechanical device that allows fluid to flow through it in only one direction. It operates using a simple mechanism where a disc or ball is lifted off its seat by the pressure of the fluid flowing in the correct direction, and then falls back onto its seat when the flow attempts to reverse, thereby blocking the reverse flow. Check valves are commonly used in various fluid systems, including water, gas, and oil, to prevent backflow and maintain system integrity 3.

Purpose of the Cummins 4371676 Check Valve

The Cummins 4371676 Check Valve is specifically designed to function within the fuel, lubrication, or cooling systems of a truck. Its role is to ensure that fluids flow in the intended direction, which helps in maintaining the pressure and efficiency of these systems. By preventing backflow, it contributes to the stable operation of the truck’s engine and other components, enhancing overall performance and reliability 4.

Key Features

The Cummins 4371676 Check Valve is constructed from durable materials that are resistant to corrosion and wear, ensuring longevity in demanding environments. Its design includes a precision-machined seat and a robust disc or ball mechanism that ensures a tight seal against reverse flow. Additionally, the valve may feature unique attributes such as a spring-assisted closure for rapid response to flow changes, enhancing its performance in dynamic operating conditions 1.

Benefits

The advantages provided by the Cummins 4371676 Check Valve include improved system efficiency through the prevention of backflow, which can lead to energy losses and increased wear on system components. Its reliable operation contributes to the longevity of the truck’s fluid systems, reducing the need for frequent maintenance or replacements. Furthermore, the valve’s design and construction ensure it can withstand the harsh conditions typical of commercial truck operations, providing consistent performance over time 2.

Installation Considerations

When installing the Cummins 4371676 Check Valve, it is important to follow guidelines and best practices to ensure proper orientation and integration within the truck’s system. The valve should be installed in the direction of flow, with attention paid to securing it firmly in place to prevent leaks. Integration within the system should consider the valve’s compatibility with other components and the specific requirements of the truck’s fluid system 3.

Troubleshooting Common Issues

Common problems associated with check valves include leakage, failure to open or close properly, and blockages. Diagnosing these issues may involve checking for physical damage, ensuring proper installation, and verifying that the valve is compatible with the system’s fluid type and pressure. Recommended solutions or maintenance practices may include cleaning the valve, replacing worn components, or adjusting the system to ensure optimal valve operation 4.

Maintenance Tips

Routine maintenance practices for the Cummins 4371676 Check Valve are crucial for ensuring optimal performance and longevity. These practices may include regular inspection for signs of wear or damage, cleaning to remove any debris that could impede operation, and testing the valve’s function to ensure it opens and closes as intended. Replacement guidelines should be followed when the valve shows significant wear or fails to operate correctly, to maintain system efficiency and reliability 1.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle operators worldwide 2.

Compatibility with Engine Models

The Cummins Check Valve 4371676 is designed to ensure unidirectional fluid flow, preventing backflow in various engine systems. This part is compatible with several engine models, including the QST30 CM2350 T101 and QST30 CM552.

For the QST30 CM2350 T101 engine, the check valve is engineered to integrate seamlessly with the engine’s hydraulic and lubrication systems. It ensures that fluid flows in the correct direction, maintaining system efficiency and preventing potential damage from backflow.

Similarly, in the QST30 CM552 engine, the check valve 4371676 plays a crucial role in maintaining the integrity of the engine’s fluid systems. Its design allows it to fit precisely within the engine’s architecture, ensuring optimal performance and longevity.

Both engines benefit from the check valve’s ability to maintain consistent fluid pressure and flow, which is essential for the smooth operation of the engine’s various components. The compatibility of the Cummins Check Valve 4371676 with these engines underscores its versatility and importance in ensuring engine reliability and efficiency 3.

Role in Engine Systems

The 4371676 Check Valve is an integral component in various engine systems, ensuring the smooth and efficient operation of several key functions.

In the plumbing system, the check valve prevents the backflow of fluids, maintaining the integrity of the system by ensuring that fluids move in the intended direction. This is particularly important in systems where fluid dynamics are complex and backflow could lead to contamination or system failure.

Within the engine oil primer system, the check valve plays a significant role by allowing oil to flow into the engine during the priming phase while preventing any reverse flow. This ensures that the engine receives a consistent supply of oil, which is essential for lubrication and cooling. The primer system relies on the check valve to maintain pressure and prevent oil from draining back, which could result in inadequate lubrication upon engine start-up.

Similarly, in the primer system for fuel, the check valve ensures that fuel flows in the correct direction, aiding in the efficient start-up of the engine. It prevents fuel from flowing back into the supply lines, which could cause inconsistent fuel delivery and affect engine performance.

In the engine lubricating system, the check valve helps maintain the proper pressure and flow of lubricants. By preventing backflow, it ensures that lubricants reach all moving parts consistently, reducing wear and tear and enhancing the longevity of the engine components.

Overall, the 4371676 Check Valve is a vital component that contributes to the reliability and efficiency of engine systems by regulating fluid flow and preventing backflow in critical applications 4.

Conclusion

The Cummins 4371676 Check Valve is a critical component in the maintenance and operation of commercial truck systems. Its role in preventing backflow ensures the efficiency and reliability of the truck’s fluid systems, contributing to the overall performance and longevity of the vehicle. Proper installation, maintenance, and troubleshooting are essential to maximize the benefits of this Cummins part, ensuring consistent and reliable operation in demanding environments.

-

Klyde, Michael and VanGelder, Kirk. Advanced Automotive Electricity and Electronics. Jones Bartlett Learning, 2010.

↩ ↩ -

Quigley, Jon M. SAE International’s Dictionary of Testing, Verification and Validation. SAE International, 2023.

↩ ↩ ↩ -

Reif, Konrad Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ ↩ ↩ -

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.