This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

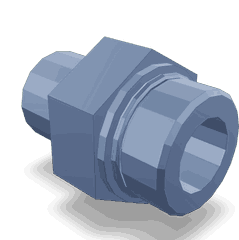

The Cummins Part #4385686 Check Valve is a component designed for use in commercial truck systems. Manufactured by Cummins Inc., a well-established name in the commercial vehicle industry, this check valve serves a specific function within the operational framework of trucks. Its role is to ensure the unidirectional flow of fluids, contributing to the efficient and reliable performance of the vehicle’s systems.

Basic Concepts of Check Valves

Check valves, also known as non-return valves, are devices that allow fluid to flow in one direction only, preventing backflow. They operate using a mechanism that opens under pressure from the flow direction and closes when the flow reverses or stops, thus maintaining the intended direction of fluid movement. These valves find applications in various fluid systems, including fuel, lubrication, and hydraulic systems, where controlling the flow direction is necessary for system integrity and performance 1.

Purpose of the 4385686 Check Valve in Truck Operations

In the context of commercial trucks, the 4385686 Check Valve plays a role in ensuring the proper flow of fluids within the fuel, lubrication, or hydraulic systems. By preventing backflow, it helps maintain system pressure and efficiency, ensuring that fluids reach their intended destinations without interference from reverse flow. This function is vital for the consistent operation of the truck’s engine and other systems that rely on fluid dynamics for performance 2.

Key Features

The 4385686 Check Valve is characterized by its robust design and the quality materials used in its construction. These features contribute to its durability and reliability in demanding commercial truck environments. The valve’s design may include a spring-loaded mechanism or a swing check design, depending on the specific application requirements. The materials, often metal alloys, are chosen for their resistance to corrosion and wear, ensuring long-term performance 3.

Benefits of Using the 4385686 Check Valve

Incorporating the 4385686 Check Valve into truck systems offers several advantages. It enhances system efficiency by ensuring fluids flow in the correct direction, reducing the risk of system failures due to backflow. The valve’s reliable operation contributes to the overall reliability of the truck’s systems, potentially reducing maintenance needs and operational downtime. Additionally, by preventing fluid contamination and system damage, it can offer cost-saving benefits for fleet operators.

Installation Considerations

When installing the 4385686 Check Valve, it is important to follow guidelines to ensure proper function and integration within the system. This includes orienting the valve correctly to allow for the intended flow direction, using the appropriate tools for installation, and ensuring compatibility with the existing system components. Proper installation is key to maximizing the valve’s performance and longevity.

Troubleshooting Common Issues

Check valves, including the 4385686, may encounter issues such as leakage or failure to open/close properly. Diagnosing these problems involves checking for signs of wear, corrosion, or obstruction within the valve mechanism. Solutions may range from cleaning and maintenance to replacement, depending on the severity of the issue. Regular inspection and maintenance can help prevent many common problems.

Maintenance Tips

To ensure the longevity and optimal performance of the 4385686 Check Valve, routine maintenance is recommended. This includes regular inspection for signs of wear or damage, cleaning the valve to remove any debris that may affect its operation, and testing its function periodically. Adhering to manufacturer guidelines for maintenance intervals and procedures can help maintain the valve’s efficiency and reliability.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial vehicle industry. The company’s product range includes engines, powertrains, and related components, serving a wide array of industries and applications. Cummins’ commitment to excellence and customer satisfaction has made it a preferred choice for commercial vehicle operators worldwide.

Cummins Check Valve Part 4385686 Compatibility

The Cummins Check Valve part number 4385686 is designed to ensure unidirectional flow in various engine systems, preventing backflow and maintaining system integrity. This part is compatible with several Cummins engine models, including the QSK95 CM2350 K111 and QSK95 CM2350 K113.

QSK95 CM2350 K111 and QSK95 CM2350 K113

For the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines, the check valve part 4385686 plays a role in maintaining the efficiency and reliability of the engine’s lubrication and fuel systems. Its design ensures that fluids flow in the intended direction, which is important for the proper functioning of these high-performance engines.

The check valve is engineered to withstand the demanding conditions of these engines, including high pressures and temperatures. Its robust construction ensures longevity and consistent performance, making it an important component for maintaining the operational integrity of the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines.

Role of Part 4385686 Check Valve in Engine Systems

The Part 4385686 Check Valve is a component in ensuring the efficient operation of engine systems, particularly in relation to the primer and engine lubrication mechanisms.

Integration with the Primer System

In the primer system, the Check Valve plays a role by regulating the flow of fuel. It allows fuel to move in one direction only, preventing any backflow that could disrupt the priming process. This ensures that the fuel system is pressurized correctly, facilitating smooth engine startup. The valve’s precise control over fuel flow helps maintain consistent pressure levels, which is important for the primer’s effectiveness in delivering fuel to the engine cylinders.

Contribution to Engine Lubrication

Within the engine lubrication system, the Check Valve is instrumental in managing oil flow. It ensures that oil is directed efficiently to various engine components, such as bearings and pistons, without any reverse flow. This consistent oil supply is essential for reducing friction and wear on moving parts, thereby enhancing the engine’s longevity and performance. The valve’s ability to maintain unidirectional oil flow helps in sustaining optimal lubrication conditions, which is fundamental for the engine’s reliable operation.

Conclusion

In summary, the Part 4385686 Check Valve is a key component in both the primer and engine lubrication systems, ensuring that fluids are delivered efficiently and consistently to where they are needed most. Its robust design, compatibility with high-performance Cummins engines, and role in maintaining system integrity and efficiency make it an essential part for commercial truck operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.