This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4900590 Pressure Relief Valve is a critical component designed to maintain operational safety and efficiency in commercial trucks. This valve regulates pressure levels within the truck’s systems, ensuring they operate within safe parameters. It contributes to the vehicle’s overall functionality and reliability, enhancing both performance and longevity.

Basic Concepts of Pressure Relief Valves

A pressure relief valve is a device that automatically releases excess pressure from a system to prevent over-pressurization. It opens when the pressure exceeds a predetermined set point, allowing fluid or gas to escape and reducing the pressure. This mechanism is vital for maintaining system integrity, protecting components from damage due to excessive pressure, and ensuring safe operation 1.

Purpose of the 4900590 Pressure Relief Valve

The Cummins 4900590 Pressure Relief Valve is designed to manage pressure levels within the truck’s systems. By ensuring that the pressure does not exceed safe limits, this valve helps prevent component failure or other operational issues. It plays a role in maintaining the efficiency and reliability of the truck’s systems 2.

Key Features

The Cummins 4900590 Pressure Relief Valve features a robust design with high-quality materials for durability and performance. It is engineered with precision to provide accurate pressure regulation. Unique characteristics may include its ability to withstand high temperatures and pressures, as well as its design for easy installation and maintenance.

Benefits

The benefits of the Cummins 4900590 Pressure Relief Valve include enhanced safety through effective pressure management, improved system efficiency by maintaining optimal pressure levels, and prolonged component lifespan due to reduced stress on system components. These advantages contribute to the overall reliability and performance of the truck 3.

Installation Considerations

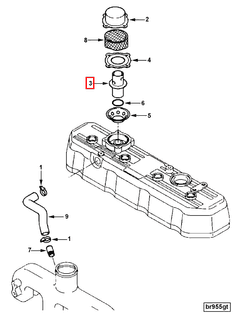

Proper installation of the Cummins 4900590 Pressure Relief Valve is essential for its effective operation. Guidelines for installation include ensuring the valve is correctly oriented, securely fastened, and connected to the appropriate system components. It is also important to follow manufacturer recommendations to avoid common pitfalls such as incorrect placement or inadequate sealing, which could lead to system malfunctions.

Troubleshooting

Common issues with pressure relief valves may include failure to open at the correct pressure, leaks, or blockages. Diagnosing problems involves checking the valve’s operation against its specified pressure settings, inspecting for physical damage or wear, and ensuring there are no obstructions in the system. Effective troubleshooting may require adjusting the valve settings, cleaning or replacing the valve, or addressing issues within the system that could be affecting valve performance.

Maintenance

Recommended maintenance practices for the Cummins 4900590 Pressure Relief Valve include regular inspection for signs of wear or damage, cleaning to remove any contaminants that could affect operation, and testing to ensure it opens and closes at the correct pressures. Replacement should be considered if the valve shows significant wear, fails to operate correctly, or if system requirements change.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry for producing reliable and efficient components that contribute to the performance and safety of vehicles.

Compatibility with Cummins Engines

The Pressure Relief Valve 4900590, manufactured by Cummins, is designed to fit seamlessly within a range of Cummins engines. This valve is a critical component in maintaining the operational integrity of the engine by regulating and controlling the pressure within the hydraulic system.

A1400 and A1700 Engines

For the A1400 and A1700 engines, the Pressure Relief Valve 4900590 is engineered to integrate smoothly into the engine’s hydraulic system. These engines, known for their reliability and efficiency, benefit from the precise pressure regulation provided by this valve, ensuring optimal performance and longevity.

A2000 and A2300 Engines

Similarly, the A2000 and A2300 engines are compatible with the Pressure Relief Valve 4900590. These engines, which are part of Cummins’ higher power output range, require robust pressure management to handle increased operational demands. The valve’s design ensures that the hydraulic pressure remains within safe limits, preventing potential damage to the engine components.

Grouping of Engines

When considering the A1400 and A1700 engines together, it’s evident that the Pressure Relief Valve 4900590 is a versatile component suitable for both medium-duty and light-duty applications. This valve’s compatibility with these engines underscores its importance in maintaining system stability and efficiency.

For the A2000 and A2300 engines, the Pressure Relief Valve 4900590 is equally essential. These engines, designed for heavy-duty applications, benefit from the valve’s ability to manage higher pressures, ensuring that the engine operates smoothly under demanding conditions.

Role of Part 4900590 Pressure Relief Valve in Engine Systems

The Part 4900590 Pressure Relief Valve is a critical component in managing the pressure dynamics within various engine systems. Its primary function is to regulate and release excessive pressure that builds up in the crankcase and breather systems, ensuring optimal engine performance and longevity.

Integration with the Crankcase

In the crankcase, the pressure relief valve plays a significant role in maintaining a stable internal pressure. As the engine operates, combustion byproducts and blow-by gases accumulate within the crankcase. If left unchecked, this buildup can lead to increased pressure, potentially causing oil leaks, gasket failures, and other mechanical issues. The pressure relief valve mitigates these risks by venting excess pressure to a safe location, typically the intake manifold or a dedicated breather system.

Interaction with the Crankcase Breather

The crankcase breather system is designed to expel contaminants and gases from the crankcase. The pressure relief valve works in tandem with the crankcase breather to ensure that the pressure within the crankcase remains within safe limits. When the pressure exceeds a predetermined threshold, the valve opens, allowing the excess pressure to escape. This action not only protects the crankcase integrity but also enhances the efficiency of the breather system by preventing backpressure that could impede the expulsion of contaminants.

Coordination with the Breather System

The breather system is responsible for allowing fresh air into the crankcase while expelling old air and contaminants. The pressure relief valve ensures that this process occurs without undue pressure buildup. By maintaining a balanced pressure environment, the valve supports the breather system’s ability to effectively manage crankcase ventilation, which is vital for maintaining clean oil and reducing the risk of sludge formation.

Conclusion

In summary, the Cummins 4900590 Pressure Relief Valve is integral to the efficient operation of the crankcase, crankcase breather, and overall breather system. Its role in pressure regulation helps protect engine components, ensures smooth operation, and contributes to the longevity of the engine. Proper installation, maintenance, and troubleshooting are essential to maximize the benefits of this critical component.

-

Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, Springer, 2018

↩ -

Automotive Mechatronics Operational and Practical Issues Volume 1, BT Fijalkowski, Springer, 2011

↩ -

Transmissions and Drivetrain Design, Michael Hilgers, Springer Vieweg, 2022

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.