This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

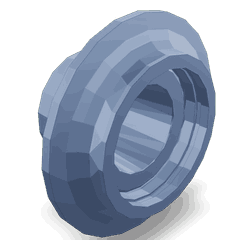

The 4906477 Valve Spring Retainer, a component manufactured by Cummins, is designed to play a role in the operation of heavy-duty trucks. This part is integral to the valve train system, ensuring that the valves within the engine operate correctly. Cummins, a well-established manufacturer in the automotive industry, is known for its commitment to quality and innovation in producing reliable automotive components.

Function and Operation

The Valve Spring Retainer operates by securing the valve spring to the valve stem within the engine. Its role is to maintain the integrity of the valve train by keeping the valve spring in place, which is essential for the proper opening and closing of the engine’s valves. This ensures that the air-fuel mixture enters and exits the combustion chamber at the correct times, which is fundamental for the engine’s performance 1.

Key Features

This Cummins part is characterized by its robust design and the quality of materials used in its construction. It is made from high-strength materials that offer resistance to wear and corrosion, ensuring durability under the demanding conditions typical of heavy-duty truck engines. The design of the retainer is optimized to distribute stress evenly, enhancing its performance and longevity.

Benefits

Utilizing the Valve Spring Retainer can lead to improved engine efficiency and reliability. Its durable construction and precise design contribute to the overall longevity of the engine, reducing the likelihood of valve train failures. This, in turn, can lead to lower maintenance costs and increased uptime for heavy-duty trucks.

Installation and Compatibility

Proper installation of the Valve Spring Retainer is crucial for its effective operation. It is designed to be compatible with specific engine models, ensuring a precise fit and function. Installation guidelines should be followed to maintain the integrity of the valve train system and to ensure the retainer operates as intended.

Maintenance and Troubleshooting

Regular maintenance practices are recommended to ensure the longevity of the Valve Spring Retainer. This includes periodic inspections for signs of wear or damage. Common issues may include spring displacement or retainer failure, which can be addressed through proper troubleshooting steps and, if necessary, replacement of the component.

Performance Under Stress

The Valve Spring Retainer is engineered to perform under various operating conditions, including high RPMs and heavy loads. Its design and material properties allow it to withstand the stresses associated with heavy-duty truck applications, ensuring reliable valve operation even under demanding conditions.

Material Durability

The materials used in the construction of the Valve Spring Retainer are selected for their resistance to wear, corrosion, and thermal stress. This ensures that the component can endure the harsh environments and high temperatures within the engine, contributing to its durability and reliability.

Design Innovations

The Valve Spring Retainer incorporates design innovations that enhance its function and reliability. These may include features that improve stress distribution, reduce the likelihood of failure, and ensure precise valve operation. Such innovations are a testament to Cummins’ commitment to quality and performance in their products.

Compatibility with Cummins Engines

The Valve Spring Retainer part number 4906477 is designed to fit seamlessly with several Cummins engine models, providing a reliable and durable solution for maintaining the integrity of the valve spring assembly.

QSK60 and QSK60 G Engines

The Valve Spring Retainer part 4906477 is specifically engineered to fit the QSK60 and QSK60 G engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications such as marine and industrial settings. The part ensures that the valve springs are securely held in place, preventing any potential failure that could lead to engine damage.

CM2358 and K110 Engines

Similarly, the Valve Spring Retainer part 4906477 is also compatible with the CM2358 and K110 engines. These engines are part of Cummins’ extensive lineup, designed to deliver high performance and efficiency across various applications. The part’s precision fit and durability make it an essential component for maintaining the operational integrity of these engines.

Grouping of Compatible Engines

The Valve Spring Retainer part 4906477 is designed to fit within the following groups of Cummins engines:

- QSK60 Series: This includes the QSK60 and QSK60 G engines, both of which benefit from the part’s ability to maintain the valve spring assembly’s integrity.

- CM2358 and K110 Series: These engines also rely on the part to ensure that the valve springs are securely retained, contributing to the overall performance and longevity of the engine.

Role of Valve Spring Retainer in Engine Systems

The Valve Spring Retainer is an essential component in the orchestration of an engine’s valve train system. Its primary function is to secure the valve spring in place, ensuring that the spring remains correctly positioned over the valve stem. This is vital for the proper operation of the valve, which must open and close at precise intervals to allow the intake and exhaust of gases in the combustion process.

When integrated with the camshaft, the Valve Spring Retainer works in harmony to maintain the timing and pressure of the valve operation. The camshaft, through its lobes, actuates the valves, and the Valve Spring Retainer ensures that the spring can apply consistent force to close the valve after actuation.

In conjunction with the connecting rod and piston assembly, the Valve Spring Retainer indirectly influences the engine’s power output. The efficient opening and closing of valves, facilitated by the retainer, allow for optimal air-fuel mixture intake and exhaust gas evacuation, which is critical for the piston’s movement within the cylinder.

The cylinder head is another component where the Valve Spring Retainer plays a significant role. It is mounted within the cylinder head, and its function is to keep the valve spring compressed, ready to exert force on the valve stem. This ensures that the valve seals properly against the seat, preventing any leaks that could compromise engine efficiency.

When considering a cylinder head rebuild kit, the inclusion of a Valve Spring Retainer like part 4906477 is often necessary. It is a component that, while small, has a significant impact on the rebuild’s success. A failed or worn Valve Spring Retainer can lead to valve train noise, reduced performance, and potential engine damage.

In the realm of performance parts, upgrading to a high-quality Valve Spring Retainer can contribute to enhanced engine performance. It can support higher spring pressures required for increased valve lift and duration, which are common modifications in performance engine builds.

Conclusion

Overall, the Valve Spring Retainer is a component that, while often overlooked, is fundamental to the reliable and efficient operation of an engine’s valve train system. Its role in maintaining the integrity and function of the valve spring is indispensable for the overall performance and longevity of the engine.

-

Hilgers, Michael. The Drivers Cab. Springer Vieweg, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.