This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4949132 Valve Insert is a component designed for use in heavy-duty truck engines. It plays a role in maintaining engine performance by ensuring proper valve operation. This part is integral to the valve train system, which is essential for the engine’s overall efficiency and durability.

Basic Concepts of Valve Inserts

Valve inserts are components placed within the cylinder head to provide a durable surface for the valve seat. They facilitate the opening and closing of the valves, which control the intake of air and fuel and the exhaust of combustion gases. Valve inserts interact with other components such as the valve seat and valve stem, contributing to the sealing and seating mechanisms that are vital for engine function 1.

Purpose of the 4949132 Valve Insert

The 4949132 Valve Insert is designed to enhance the operation of truck engines by ensuring proper valve seating and sealing. It maintains the integrity of the valve seat, which is subject to high temperatures and pressures. By providing a robust and wear-resistant surface, the insert helps to maintain a tight seal between the valve and the seat, which is necessary for efficient combustion and reduced emissions 2.

Key Features

The 4949132 Valve Insert is characterized by specific design and material attributes that enhance its durability and performance. It is typically made from high-quality materials that can withstand the harsh conditions within an engine. Precision machining ensures that the insert fits accurately within the cylinder head, while heat treatment processes improve its hardness and resistance to wear. These features contribute to the insert’s ability to perform reliably over the engine’s lifespan 3.

Benefits

The advantages provided by the 4949132 Valve Insert include improved engine efficiency, reduced wear on valve seats, and enhanced longevity of engine components. By ensuring a consistent and reliable seal, the insert helps to maintain optimal combustion conditions, which can lead to better fuel efficiency and lower emissions. Additionally, the durable construction of the insert reduces the frequency of maintenance and replacement, contributing to the overall cost-effectiveness of engine operation.

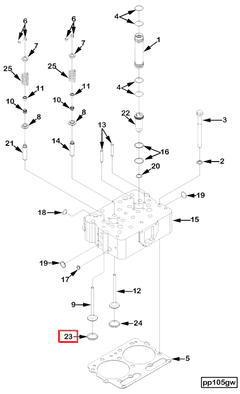

Installation Process

Proper installation of the 4949132 Valve Insert involves several steps to ensure it functions correctly. The process begins with the preparation of the cylinder head, which may include cleaning and inspection to ensure there are no obstructions or damage. The insert is then positioned within the valve seat, and various tools and techniques may be used to secure it in place. It is important to follow manufacturer guidelines to avoid common pitfalls such as improper seating or damage to the insert during installation.

Troubleshooting and Maintenance

Identifying common issues related to valve inserts, such as leaks or improper seating, is important for maintaining engine performance. Regular inspection and maintenance can help to detect early signs of wear or damage. Practices such as monitoring engine performance, checking for unusual noises or vibrations, and performing routine valve adjustments can contribute to the optimal performance and longevity of the valve insert and associated components.

Cummins Corporation Overview

Cummins Inc. is a well-established company with a significant presence in the heavy-duty truck industry. Founded in 1919, Cummins has a long history of innovation and quality in engine design and manufacturing. The company offers a wide range of products, including engines, filtration systems, and power generation equipment. Cummins is known for its commitment to quality and reliability, making it a trusted name in the industry for heavy-duty applications.

Role of Part 4949132 Valve Insert in Engine Systems

The 4949132 Valve Insert is an integral component in the orchestration of engine performance, interacting with several key components to ensure optimal functionality.

Interaction with the Cylinder Head

The Valve Insert is positioned within the cylinder head, where it serves as a durable interface between the valve and the head itself. This placement allows for efficient heat dissipation from the valve to the cylinder head, which is vital for maintaining the integrity of the valve under high-temperature conditions.

Relationship with the Valve and Camshaft

As the camshaft actuates the valve through the use of lifters and pushrods (in overhead valve engines) or directly via rocker arms (in overhead cam engines), the Valve Insert ensures a smooth and consistent operation. It absorbs the impact forces generated during the opening and closing of the valve, thereby prolonging the lifespan of both the valve and the cylinder head.

Contribution to Engine Performance

In high-performance engines, where valves operate at increased frequencies and under greater stress, the 4949132 Valve Insert plays a significant role. It allows for precise valve seating, which is essential for maintaining the correct valve timing and ensuring that the air-fuel mixture is inducted and exhausted at the optimal moments.

Integration with the Crosshead and Cylinder

In engines that utilize a crosshead design, the Valve Insert’s role extends to supporting the structural integrity of the valve train. It must withstand the lateral forces exerted by the crosshead as it reciprocates, which can be substantial in high-output engines.

Overall Engine Harmony

The Valve Insert is a linchpin in the symphony of engine components. It facilitates the seamless interaction between the camshaft, cylinder head, and valve, contributing to the engine’s overall efficiency, reliability, and performance. Its proper function is indicative of a well-maintained engine, capable of delivering consistent power output and longevity.

Conclusion

The 4949132 Valve Insert by Cummins is a critical component in the maintenance and performance of heavy-duty truck engines. Its design and material attributes ensure durability and reliable operation, contributing to engine efficiency, reduced wear, and enhanced longevity. Proper installation and maintenance are essential to maximize the benefits of this Cummins part, ensuring optimal engine performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.