This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

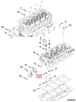

The Cummins 5262813 Valve Insert is a component designed for use in heavy-duty truck engines. Its purpose is to enhance the durability and performance of the engine’s valve system. By addressing common issues related to valve seat wear, this valve insert contributes to the overall efficiency and longevity of the engine.

Basic Concepts of Valve Inserts

Valve inserts are components placed within the cylinder head of an engine to protect the valve seats from excessive wear 1. They play a role in maintaining the integrity of the valve seating surface, which is crucial for proper valve operation and sealing. By providing a harder and more wear-resistant surface than the cylinder head material, valve inserts help to extend the life of the engine and improve its performance 2.

Purpose of the Cummins 5262813 Valve Insert

The Cummins 5262813 Valve Insert is specifically designed to manage valve seat wear in truck engines. It ensures that the valve seats remain in optimal condition, which is vital for maintaining proper valve operation. This insert helps in reducing the frequency of valve seat repairs and replacements, thereby contributing to the engine’s overall efficiency and reliability.

Key Features

The Cummins 5262813 Valve Insert is characterized by its material composition and design. It is typically made from a durable alloy that offers superior wear resistance compared to standard cylinder head materials. The design of the insert allows for easy installation and integration with the engine’s valve system, ensuring a precise fit and optimal performance.

Benefits of Using the Cummins 5262813 Valve Insert

Utilizing the Cummins 5262813 Valve Insert offers several advantages. It contributes to improved engine efficiency by ensuring that the valve seats remain in good condition, which is essential for proper valve operation 3. Additionally, it reduces maintenance requirements by minimizing the wear on valve seats, leading to fewer repairs and replacements. The enhanced durability of the valve seats also contributes to the overall longevity of the engine components 4.

Installation and Compatibility

Proper installation of the Cummins 5262813 Valve Insert involves following specific procedures to ensure it is correctly positioned within the cylinder head. This may require the use of specialized tools and techniques to achieve a precise fit. The insert is compatible with various Cummins engine models, making it a versatile component for maintaining and upgrading heavy-duty truck engines.

Troubleshooting and Maintenance

Identifying common issues related to valve inserts involves monitoring the engine’s performance and conducting regular inspections of the valve seats. Diagnostic procedures may include checking for signs of wear, such as uneven surfaces or damage to the valve seats. Maintenance practices for the Cummins 5262813 Valve Insert include ensuring it is properly seated and monitoring its condition during routine engine servicing to ensure optimal performance and longevity.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer in the heavy-duty truck industry, known for its commitment to innovation and quality. With a diverse product range that includes engines, filtration systems, and power generation equipment, Cummins has built a reputation for delivering reliable and high-performance solutions. The company’s focus on research and development ensures that its products meet the evolving needs of the industry, providing customers with advanced technology and superior performance.

Compatibility with Cummins Engine Models

The Valve Insert part 5262813, manufactured by Cummins, is designed to fit seamlessly with a variety of engine models. This part is crucial for the proper functioning of the engine’s valve system, ensuring efficient operation and longevity.

For the F2.8 CM2620 F135B engine, the Valve Insert part 5262813 is engineered to integrate perfectly with the engine’s design, providing a reliable seal and smooth operation. Similarly, for the ISF2.8 CM2220 F117 and ISF2.8 CM2220 F129 engines, this part ensures that the valve mechanisms operate without friction, contributing to the engine’s overall performance.

In the case of the QSF2.8 CM2880 series, which includes the F104, F105, F108, and F114 models, the Valve Insert part 5262813 is tailored to fit the specific valve configurations of these engines. This ensures that the valves can open and close as intended, maintaining the engine’s efficiency and reliability.

Lastly, for the R2.8 CM2220 R101B engine, the Valve Insert part 5262813 is designed to align with the engine’s unique valve setup, providing the necessary support and functionality for optimal engine performance.

Conclusion

The Cummins 5262813 Valve Insert is an integral component within the engine’s cylinder head assembly. Its primary function is to provide a durable seating surface for the valve within the cylinder head. This ensures a proper seal between the valve and the head, which is essential for maintaining the engine’s efficiency and performance 1. When the valve is actuated, the Valve Insert allows for a precise and consistent seal, preventing any leakage of combustion gases into the intake or exhaust pathways. This seal is vital for the engine’s ability to maintain compression and deliver power effectively 2. Moreover, the Valve Insert is designed to withstand the high temperatures and pressures present within the cylinder head. Its material properties are selected to endure the thermal and mechanical stresses that occur during engine operation, thereby prolonging the lifespan of the valve and the cylinder head itself 3. In summary, the Valve Insert plays a significant role in the functionality and durability of the cylinder head, ensuring that the valve operates within its designed parameters, contributing to the overall performance and reliability of the engine 4.

-

Mananathan, R. (2022). Automobile Wheel Alignment and Wheel Balancing. SAE International.

↩ ↩ -

Nunney, MJ. (2007). Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann.

↩ ↩ -

Schneider, Wolf-Henning. (2016). Pistons and Engine Testing. Springer Nature.

↩ ↩ -

Xin, Qianfan. (2011). Diesel Engine System Design. Woodhead Publishing Limited.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.