This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

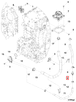

The Cummins 5267080 Check Valve is a component designed for use in commercial truck systems. It serves to regulate the flow of fluids, ensuring that they move in a single direction within the system. This valve is integral to maintaining the efficiency and reliability of the truck’s operations, particularly within the fuel or hydraulic systems.

Basic Concepts of Check Valves

Check valves are mechanical devices that allow fluid to flow through them in one direction only. They automatically prevent reverse flow, which can be crucial in systems where backflow could cause damage or reduce efficiency. These valves operate using a simple mechanism where a disc or ball moves to block the flow when pressure is applied in the wrong direction. Check valves find applications in various fluid systems, including water, air, and fuel systems, across multiple industries 1.

Purpose of the 5267080 Check Valve

In the context of a commercial truck, the 5267080 Check Valve plays a specific role within the fuel or hydraulic systems. It ensures that fuel or hydraulic fluid flows in the correct direction, preventing backflow that could lead to system inefficiencies or damage. By maintaining proper fluid direction, the valve contributes to the stable operation of the truck’s engine or hydraulic components 2.

Key Features

The 5267080 Check Valve is characterized by its robust design and the quality materials used in its construction. It is engineered to withstand the high pressures and temperatures typical in commercial truck environments. Unique attributes of this valve include its precision-machined components and durable sealing materials, which enhance its performance and longevity 3.

Benefits

The advantages of incorporating the 5267080 Check Valve into a commercial truck’s system include improved efficiency and reliability. By ensuring unidirectional fluid flow, the valve helps maintain system pressure and performance. Additionally, its durable construction reduces the need for frequent replacements, offering cost savings for fleet operators over time.

Installation Considerations

When installing the 5267080 Check Valve, it is important to follow guidelines to ensure proper integration within the existing system. This includes orienting the valve correctly to allow for the intended direction of fluid flow. The installation may require specific tools, and it is advisable to consult the manufacturer’s instructions for detailed steps and recommendations.

Troubleshooting Common Issues

Typical problems that may arise with the 5267080 Check Valve include leaks or malfunctions due to wear or improper installation. Diagnostic steps may involve checking the valve’s orientation, inspecting seals for damage, and ensuring that the valve is compatible with the system’s pressure and temperature requirements.

Maintenance Tips

To ensure the longevity and optimal performance of the 5267080 Check Valve, regular maintenance practices are recommended. This includes periodic inspection for signs of wear or damage, cleaning the valve to remove any debris that could impede its operation, and replacing seals or other components as necessary to maintain a tight seal and efficient fluid flow.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s commitment to excellence is reflected in its wide range of products, including the 5267080 Check Valve, which is designed to meet the demanding requirements of commercial truck applications.

Cummins Check Valve 5267080 Compatibility

The Cummins Check Valve 5267080 is a component in the engine’s fuel system, ensuring that fuel flows in the correct direction and preventing backflow. This check valve is designed to fit a variety of Cummins engines, providing a reliable solution for maintaining fuel system integrity.

Compatible Engines

- 15N CM2380 M104B

- B4.5 CM2350 B129B

- B5.6 CM2670 B152B

- B6.7 CM2670 B153B

- B6.7 G CMOH6.0 B125

- D4.0 CM2620 D103B

- F3.8 CM2350 F120B

- F3.8 CM2350 F128C

- F3.8 CM2620 F137B

- F4.5 CM2620 F139B

- ISB4.5 CM2350 B104

- ISF3.8 CM2220 AN

- ISF3.8 CM2350 F109

- ISF4.5 CM2220 F123

- ISG12 G CMOH6.0 G111

- QSF3.8 CM2350 F107

- QSK19 CM2350 K114

- X11 CM2670 X126B

- X12N CMMDG1 X143B

Grouping by Engine Series

CM2350 Series

- B4.5 CM2350 B129B

- ISB4.5 CM2350 B104

- ISF3.8 CM2350 F109

- QSF3.8 CM2350 F107

CM2620 Series

- D4.0 CM2620 D103B

- F3.8 CM2620 F137B

- F4.5 CM2620 F139B

CM2670 Series

- B5.6 CM2670 B152B

- B6.7 CM2670 B153B

- X11 CM2670 X126B

CM2220 Series

- ISF3.8 CM2220 AN

- ISF4.5 CM2220 F123

CMOH6.0 Series

- B6.7 G CMOH6.0 B125

- ISG12 G CMOH6.0 G111

CMMDG1 Series

- X12N CMMDG1 X143B

K114 Series

- QSK19 CM2350 K114

This comprehensive compatibility ensures that the Cummins Check Valve 5267080 can be used across a wide range of engine models, providing a versatile solution for maintaining optimal engine performance.

Role of Part 5267080 Check Valve in Engine Systems

The part 5267080 Check Valve is an integral component in the arrangement of various engine systems, ensuring efficient operation and maintaining the integrity of the engine’s internal environment.

In the crankcase breather system, the Check Valve is positioned to allow the release of pressure buildup within the crankcase while preventing the ingress of contaminants. This is vital for maintaining clean crankcase conditions, which in turn ensures the longevity and performance of the engine.

When integrated with the breather system, the Check Valve facilitates the controlled venting of gases and moisture that accumulate within the crankcase. This helps in reducing the risk of oil dilution and sludge formation, which can adversely affect engine performance.

In the context of the crankcase itself, the Check Valve plays a role in preserving the vacuum integrity. By allowing gases to escape only when pressure exceeds a certain threshold, it helps in maintaining optimal crankcase pressure, which is essential for proper engine function.

The lubricating oil drain tube benefits from the inclusion of the Check Valve by ensuring that oil does not backflow into the crankcase when the engine is not in operation. This helps in keeping the oil clean and free from contaminants that may have accumulated in the crankcase.

Lastly, when connected to a molded hose within the engine system, the Check Valve ensures that the flow of gases is unidirectional. This is particularly important in preventing the backflow of harmful substances that could otherwise compromise the engine’s efficiency and reliability.

Conclusion

The Cummins 5267080 Check Valve is a critical component in commercial truck systems, ensuring unidirectional fluid flow and preventing backflow that could lead to system inefficiencies or damage. Its robust design, precision-machined components, and durable sealing materials contribute to its performance and longevity. Regular maintenance and proper installation are key to ensuring the valve’s optimal performance and the overall efficiency of the truck’s engine or hydraulic systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.