This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

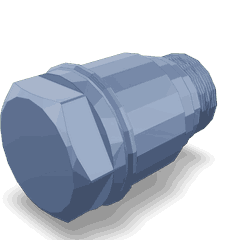

The Cummins 5317174 Pressure Relief Valve is a critical component designed to regulate pressure within the hydraulic and fuel systems of commercial trucks. Its primary function is to maintain safe operating pressures, thereby protecting the system from potential damage due to excessive pressure. This valve ensures the reliable and efficient operation of commercial trucks by preventing system failures and enhancing overall performance 3.

Basic Concepts of Pressure Relief Valves

A Pressure Relief Valve is a safety device that automatically releases excess pressure from a system to prevent damage. It operates by opening when the pressure exceeds a predetermined set point, allowing fluid to escape and thereby reducing the pressure. These valves are commonly used in various systems, including hydraulic, pneumatic, and fuel systems, to safeguard against overpressure conditions 1.

Role of the 5317174 Pressure Relief Valve in Truck Operation

The Cummins 5317174 Pressure Relief Valve plays a specific role in the hydraulic and fuel systems of commercial trucks. In the hydraulic system, it helps maintain safe operating pressures by releasing excess fluid when pressure levels surpass the set threshold. Similarly, in the fuel system, it ensures that the pressure remains within safe limits, protecting fuel lines and injectors from damage. This valve contributes to the overall safety and efficiency of the truck’s operation by preventing overpressure situations 3.

Key Features

The Cummins 5317174 Pressure Relief Valve is characterized by several key features that enhance its performance and reliability. Its design incorporates durable materials that withstand the harsh conditions of commercial truck operations. The valve has a setting range that allows for precise pressure regulation, ensuring optimal system performance. Additionally, it features a robust construction that provides longevity and resistance to wear and tear 2.

Benefits of Using the 5317174 Pressure Relief Valve

Utilizing the Cummins 5317174 Pressure Relief Valve offers several advantages. It improves system safety by preventing overpressure, which can lead to component failure. The valve enhances the performance of the hydraulic and fuel systems by maintaining consistent pressure levels. Furthermore, it contributes to the longevity of connected components by protecting them from damage caused by excessive pressure 3.

Installation Considerations

Proper installation of the Cummins 5317174 Pressure Relief Valve is vital for its effective operation. Guidelines for installation include ensuring correct orientation to allow for proper fluid flow and pressure relief. The valve should be securely mounted to prevent movement and ensure stability. Integration within the truck’s system requires careful attention to ensure compatibility with existing components and adherence to manufacturer specifications 3.

Troubleshooting Common Issues

Common problems associated with Pressure Relief Valves include leakage, failure to open at the set pressure, and erratic operation. Potential causes may include wear and tear, incorrect setting, or contamination. Recommended troubleshooting steps involve inspecting the valve for signs of damage, verifying the setting against specifications, and cleaning or replacing the valve if necessary to ensure optimal performance 1.

Maintenance Tips

Regular maintenance of the Cummins 5317174 Pressure Relief Valve is important to ensure its continued reliable operation. Inspection intervals should be established to check for signs of wear, corrosion, or damage. Cleaning procedures may involve removing accumulated debris or contaminants that could affect valve operation. Replacement should be considered if the valve shows significant wear or if it fails to operate within specified parameters 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to quality and innovation in the automotive industry. The company offers a wide range of products designed to meet the needs of various applications, emphasizing reliability, performance, and customer satisfaction 3.

Compatibility with Cummins Engines

The Pressure Relief Valve part number 5317174, manufactured by Cummins, is designed to fit a range of Cummins engines. This part plays a crucial role in maintaining the operational integrity of the engine by regulating the pressure within the fuel system. Below is a detailed breakdown of the engines that are compatible with this pressure relief valve:

ISB/ISD Series

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

ISBE Series

- ISBE CM2150

- ISBE4 CM850

ISD Series

- ISD4.5 CM2220 D108

ISF Series

- ISF3.8 CM2220 AN

QSB Series

- QSB4.5 CM850(CM2850)

- QSB6.7 CM850(CM2850)

- QSB6.7 M CM2250

- QSB7 CM2880 B117

QSL Series

- QSL9 CM850(CM2850)

By ensuring that the Pressure Relief Valve 5317174 is correctly installed in these engines, operators can maintain the efficiency and longevity of their equipment. This compatibility ensures that the valve performs its critical function of regulating pressure, thereby protecting the engine from potential damage due to excessive pressure 3.

Role of Part 5317174 Pressure Relief Valve in Engine Systems

The part 5317174 Pressure Relief Valve is integral to maintaining optimal pressure levels within various engine systems. It is strategically positioned to interact with several key components, ensuring the engine operates efficiently and safely.

Interaction with the Fuel Manifold and Injector Plumbing

The Pressure Relief Valve works in conjunction with the fuel manifold and injector plumbing to regulate fuel pressure. By monitoring and adjusting pressure levels, it prevents excessive build-up that could lead to system failures or reduced performance. This ensures that the fuel delivered to the injectors is within the specified parameters, promoting consistent combustion and engine performance 3.

Coordination with the Injector

In the fuel injection system, the Pressure Relief Valve plays a supportive role by maintaining stable pressure conditions. This stability is essential for the injector to function correctly, delivering the precise amount of fuel required for combustion. Proper pressure regulation helps in achieving the desired fuel-air mixture, which is vital for engine efficiency and emissions control 3.

Support for the Cylinder Head and Camshaft

The Pressure Relief Valve also indirectly supports the cylinder head and camshaft by ensuring that the overall engine pressure remains within safe limits. This is particularly important during high-stress operations where pressure fluctuations can occur. By relieving excess pressure, it helps in maintaining the integrity of these components, thereby enhancing the longevity and reliability of the engine 3.

Integration with the Long Block

When considering the long block—comprising the cylinder block, crankshaft, pistons, and other essential parts—the Pressure Relief Valve ensures that internal pressures do not reach levels that could cause damage. This is especially relevant in high-performance engines where pressure management is key to achieving peak performance without compromising safety 3.

Impact on Connecting Rod and Piston

The Pressure Relief Valve also contributes to the protection of the connecting rod and piston. By regulating pressure, it helps prevent scenarios where excessive pressure could lead to mechanical stress on these components. This is vital for the smooth operation and durability of the engine, particularly in high-rev applications where components are subjected to significant forces 3.

Conclusion

The Cummins 5317174 Pressure Relief Valve is a key component in the pressure management system of an engine, interacting with various parts to ensure optimal performance, safety, and longevity. Proper installation, regular maintenance, and understanding its role within the engine system are essential for maximizing its benefits and ensuring the reliable operation of commercial trucks.

-

Boyce, M. P. (2011). Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann.

↩ ↩ -

Reif, K. (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ ↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.