This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

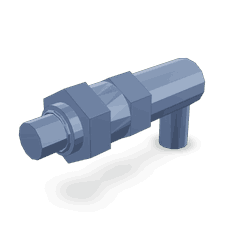

The Cummins 5364154 Sampling Valve is a component designed for use in commercial trucks. It serves a specific function within the vehicle’s fuel system, contributing to the overall efficiency and reliability of the truck’s operation. Understanding its purpose and significance can help in maintaining and troubleshooting the vehicle’s fuel system.

Basic Concepts of Sampling Valves

Sampling valves are devices used in various systems to extract small amounts of fluid for testing or analysis without interrupting the system’s operation. In automotive applications, these valves allow for the collection of fuel samples, which can be analyzed for contaminants, water content, or other impurities. This process is vital for maintaining the integrity of the fuel system and ensuring optimal engine performance 1.

Purpose of the Cummins 5364154 Sampling Valve

The Cummins 5364154 Sampling Valve plays a role in the fuel system by providing a means to extract fuel samples. This allows for regular monitoring of the fuel quality, which is important for detecting issues such as contamination or water ingress. By facilitating easy access to fuel samples, the valve contributes to the maintenance and diagnostic processes of the truck 2.

Key Features

The Cummins 5364154 Sampling Valve is characterized by its robust design and the materials used in its construction. It is built to withstand the pressures and conditions within a commercial truck’s fuel system. The valve’s design includes features that make it easy to use, such as a straightforward sampling process that requires minimal effort to operate 3.

Benefits

The advantages of using the Cummins 5364154 Sampling Valve include improved fuel system efficiency through regular monitoring and maintenance. Its design allows for quick and easy sampling, reducing downtime during maintenance checks. Additionally, the reliability of the valve ensures that it can withstand the demands of commercial truck operations, contributing to the overall durability of the fuel system 4.

Installation Process

Installing the Cummins 5364154 Sampling Valve involves several steps to ensure it is properly integrated into the fuel system. The process includes preparing the installation site, connecting the valve to the fuel line, and securing it in place. Tools and additional components may be required, depending on the specific truck model and fuel system configuration 5.

Troubleshooting Common Issues

Common problems with the Cummins 5364154 Sampling Valve may include leaks, difficulty in sampling, or valve malfunction. Troubleshooting steps involve checking the connections for tightness, ensuring the valve is correctly installed, and inspecting for any signs of damage or wear. Solutions may range from simple adjustments to replacement of the valve if necessary .

Maintenance Tips

Regular maintenance of the Cummins 5364154 Sampling Valve is important for its longevity and optimal performance. This includes periodic inspection for signs of wear or damage, ensuring all connections are secure, and cleaning the valve as needed to prevent buildup that could affect its operation. Following these practices helps maintain the efficiency of the fuel system .

Safety Considerations

When working with the Cummins 5364154 Sampling Valve, it is important to observe safety guidelines to prevent accidents. This includes ensuring the fuel system is depressurized before attempting any maintenance or installation work, using appropriate personal protective equipment, and following all manufacturer recommendations for handling and operation .

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality and performance. The company’s products, including the 5364154 Sampling Valve, are designed to meet the demanding requirements of commercial vehicle operations .

Compatibility

The Cummins Sampling Valve part number 5364154 is designed to ensure the proper functioning of various engine systems. This part is engineered to fit seamlessly within the engine architecture of several Cummins models, including the QSB6.7 M CM2250.

In the QSB6.7 M CM2250 engine, the Sampling Valve part 5364154 plays a pivotal role in maintaining the efficiency and reliability of the engine’s fuel and exhaust systems. Its precise design ensures that it integrates smoothly with the engine’s existing components, facilitating optimal performance and longevity.

The compatibility of the Cummins Sampling Valve part 5364154 extends beyond the QSB6.7 M CM2250, as it is also designed to fit within the broader family of Cummins engines. This ensures that the valve can be used across multiple engine models, providing a standardized solution for maintaining engine health and performance.

By ensuring a perfect fit and seamless integration, the Cummins Sampling Valve part 5364154 contributes to the overall efficiency and reliability of the engine systems it is installed in.

Role of Part 5364154 Sampling Valve in Engine Systems

The part 5364154 Sampling Valve is an integral component in the arrangement of engine systems, specifically designed to work in conjunction with the Oil Sampling Device. Its primary function is to facilitate the extraction of oil samples from the engine’s lubrication system. This process is essential for monitoring the condition of the engine oil, ensuring it maintains the necessary viscosity and cleanliness for optimal engine performance.

When integrated into the engine system, the Sampling Valve allows for periodic oil sampling without the need to disrupt the engine’s operation. This is achieved by providing a controlled point of access to the oil flow, enabling the Oil Sampling Device to draw a representative sample of the circulating oil. The extracted sample can then be analyzed for contaminants, wear metals, and other indicators of engine health.

The arrangement of the Sampling Valve within the engine system is strategically planned to ensure it is positioned in a location that offers a true representation of the oil’s condition throughout the engine. This typically involves placement in a section of the oil return line, where the oil has circulated through the engine and collected potential contaminants and wear particles.

The use of the Sampling Valve in conjunction with the Oil Sampling Device enhances the maintenance process by allowing for non-intrusive oil analysis. This not only aids in the early detection of potential engine issues but also contributes to the overall efficiency and reliability of the engine system. By enabling regular and systematic oil sampling, the Sampling Valve plays a significant role in the proactive maintenance of engine health, supporting the longevity and performance of the engine.

Conclusion

The Cummins 5364154 Sampling Valve is a critical component in the maintenance and operation of commercial truck fuel systems. Its robust design, ease of use, and compatibility with various Cummins engine models make it an essential tool for ensuring the efficiency and reliability of engine systems. Regular maintenance and proper installation are key to maximizing the benefits of this part, contributing to the overall performance and longevity of commercial vehicles.

-

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

Mom, G. (2023). The Evolution of Automotive Engineering: A Handbook. SAE International.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSC8.3 and QSL9 Marine. Bulletin Number 4021481.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.