This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

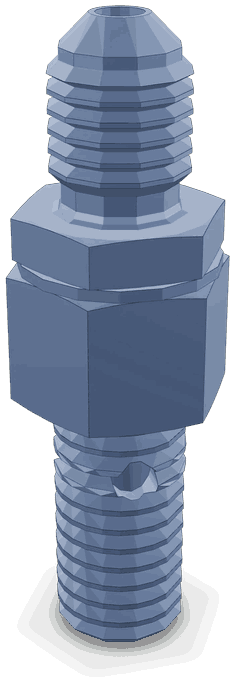

The Cummins 5403871 Check Valve is a component designed for use in commercial truck systems. Its purpose is to regulate the flow of fluids, ensuring that they move in the intended direction within the system. This valve plays a role in maintaining the efficiency and reliability of the truck’s fluid systems.

Basic Concepts of Check Valves

A check valve, also known as a non-return valve, is a device that allows fluid to flow through it in one direction only. It operates by using a mechanism that opens to permit flow in the desired direction and closes to prevent reverse flow. Check valves are commonly used in various fluid systems, including hydraulic, pneumatic, and fuel systems, to maintain pressure and prevent backflow 1.

Function and Operation of the 5403871 Check Valve

The Cummins 5403871 Check Valve functions by utilizing a spring-loaded mechanism that opens when fluid pressure from the correct direction is applied. Once the pressure drops or reverses, the spring pushes the valve closed, preventing backflow. This mechanism ensures that fluid moves consistently through the system, enhancing operational efficiency 2.

Purpose of the 5403871 Check Valve in Truck Systems

In commercial truck systems, the 5403871 Check Valve plays a role in maintaining the integrity and efficiency of fluid flow. By preventing reverse flow, it helps to maintain system pressure and ensures that components receive the necessary fluid supply. This contributes to the overall performance and reliability of the truck’s systems 3.

Key Features of the 5403871 Check Valve

The design and construction of the 5403871 Check Valve include features that enhance its performance and reliability. These features may include a durable housing material, a precision-machined valve seat, and a high-quality spring mechanism. These elements work together to ensure the valve operates effectively under various conditions 4.

Benefits of Using the 5403871 Check Valve

The advantages provided by the 5403871 Check Valve include improved system performance, reduced maintenance needs, and enhanced durability. By ensuring consistent fluid flow and preventing backflow, this valve contributes to the efficient operation of the truck’s systems. Its robust design also means it requires less frequent maintenance, offering long-term value.

Installation Considerations

When installing the 5403871 Check Valve, it is important to follow guidelines and best practices to ensure optimal performance and longevity. This includes ensuring the valve is correctly oriented to allow fluid flow in the intended direction, securing it firmly in place, and verifying that there are no obstructions or leaks in the system.

Troubleshooting Common Issues

Common problems associated with check valves can include leakage, failure to open or close properly, and blockages. To diagnose and resolve these issues, it is important to inspect the valve for signs of wear or damage, check the spring mechanism for proper function, and ensure there are no obstructions in the fluid path.

Maintenance Tips

Regular maintenance practices can help keep the 5403871 Check Valve in optimal working condition. This includes periodic inspection for signs of wear or damage, cleaning the valve to remove any buildup that could impede its function, and verifying that the spring mechanism operates correctly. Adhering to recommended inspection intervals can prolong the valve’s service life.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its wide range of products and strong reputation for quality and reliability. With a history of innovation and commitment to customer satisfaction, Cummins continues to be a leading provider of diesel engines, related technologies, and complete power solutions for commercial vehicles.

Cummins Check Valve 5403871 Compatibility

The Cummins Check Valve part number 5403871 is designed to fit seamlessly within a range of Cummins engines, ensuring optimal performance and reliability. This check valve is engineered to prevent backflow, maintaining the integrity of the system by allowing fluid to flow in one direction only.

Engine Compatibility

-

4B3.9 and 6B5.9 Engines The 5403871 check valve is compatible with both the 4B3.9 and 6B5.9 engines. These engines benefit from the check valve’s ability to maintain consistent pressure and flow, which is crucial for their operation.

-

6C8.3, L8.9 L121, and L9.5 L117 Engines The check valve also fits the 6C8.3, L8.9 L121, and L9.5 L117 engines. These engines, which may vary in size and application, rely on the check valve to ensure that fluid flow is unidirectional, preventing potential damage from backflow.

Installation and Performance

When installing the 5403871 check valve in any of these engines, it is important to follow the manufacturer’s guidelines to ensure a proper fit and function. The check valve’s design allows for easy integration into the engine’s existing system, providing a reliable solution to backflow issues.

By using the Cummins Check Valve 5403871, engine operators can expect enhanced performance and longevity of their engines, as the check valve helps maintain system efficiency and prevents potential wear and tear caused by backflow.

Role of Part 5403871 Check Valve in Engine Systems

The part 5403871 Check Valve is integral to the efficient operation of various engine systems, particularly those involving fluid dynamics. When integrated into a Fuel Shutoff Valve Kit, the check valve ensures that fuel flow is unidirectional, preventing backflow which could lead to inefficient engine performance or even damage. This is particularly important in systems where precise fuel delivery is required to maintain optimal combustion conditions.

In Plumbing applications within engine systems, the check valve serves to maintain pressure and prevent the reversal of fluid flow. This is essential in systems where consistent pressure is necessary for the proper functioning of components such as injectors or carburetors. By preventing backflow, the check valve helps in maintaining a stable pressure environment, which is vital for the reliable operation of these components.

When dealing with Fuel systems, the check valve plays a significant role in ensuring that fuel is delivered to the engine in a controlled manner. It helps in maintaining the integrity of the fuel line by preventing contaminants from traveling backward through the system. This is particularly important in high-performance engines where fuel purity directly impacts engine efficiency and longevity.

Overall, the part 5403871 Check Valve is a key component in ensuring the smooth and efficient operation of engine systems by regulating fluid flow, maintaining pressure, and preventing contamination.

Conclusion

The Cummins 5403871 Check Valve is a critical component in the maintenance and efficiency of commercial truck and engine systems. Its role in preventing backflow, maintaining system pressure, and ensuring unidirectional fluid flow is essential for the reliable operation of these systems. With its robust design and compatibility with a range of Cummins engines, this part offers long-term value and performance benefits.

-

Fundamentals of Integrated Vehicle Realization, Mohamed ElSayed PE, SAE International, 2017

↩ -

Controlling Noise and Vibration in Road Vehicles, Matthew Harrison, SAE International, 2004

↩ -

The Evolution of Automotive Engineering: A Handbook, Gijs Mom, SAE International, 2023

↩ -

Advanced Hybrid Powertrains for Commercial Vehicles Second Edition, Haoran Hu, Simon J Baseley and Xubin Song, SAE International, 2021

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.