This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The AR45632 Valve Crosshead, manufactured by Cummins, is a component designed for use in heavy-duty truck engines. Cummins, a well-established name in the engine manufacturing industry, produces this part to enhance the operational efficiency and reliability of truck engines. This Cummins part is integral to the engine’s valve train system, contributing to the overall performance and durability of the engine.

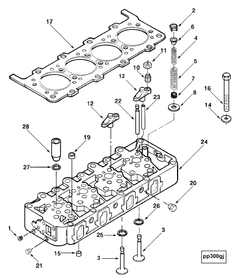

Basic Concepts of Valve Crosshead

A Valve Crosshead is a mechanical component found in the valve train of an engine. Its primary function is to facilitate the movement of the valve by connecting the valve stem to the rocker arm or other actuating mechanisms 1. This connection allows for the precise opening and closing of the engine’s valves in synchronization with the piston’s movement, which is crucial for the intake and exhaust processes. The Valve Crosshead interacts with other components such as the camshaft, pushrods, and valve springs to ensure smooth and efficient engine operation 2.

Role of the AR45632 Valve Crosshead in Truck Operation

The AR45632 Valve Crosshead plays a specific role in the operation of a truck engine by providing a stable and durable connection between the valve stem and the rocker arm. This connection is vital for maintaining the integrity of the valve train under the high stresses and temperatures encountered in heavy-duty applications 3. The AR45632 Valve Crosshead contributes to the engine’s performance and efficiency by ensuring that the valves open and close at the correct times and with the appropriate force, which is essential for optimal combustion and power output.

Key Features of the AR45632 Valve Crosshead

The AR45632 Valve Crosshead is characterized by its robust design and the use of high-quality materials. These features are intended to enhance its functionality and durability in demanding environments. The crosshead is engineered to withstand the high pressures and temperatures within the engine, ensuring reliable operation over extended periods 4. Its design also facilitates easy installation and maintenance, contributing to the overall efficiency of engine upkeep.

Benefits of Using the AR45632 Valve Crosshead

The use of the AR45632 Valve Crosshead in a truck engine can lead to several advantages. These include improved engine performance due to more precise valve operation, increased reliability under heavy-duty conditions, and enhanced longevity of the valve train components. The crosshead’s design and material properties contribute to these benefits by ensuring that the valve train operates smoothly and efficiently, even under the most demanding conditions.

Installation and Integration

Proper installation of the AR45632 Valve Crosshead is crucial for ensuring its effective operation within the engine. This process involves careful alignment with the valve stem and rocker arm, as well as ensuring that all connections are secure and free from obstructions. It is also important to follow any manufacturer-specific guidelines to ensure compatibility and optimal performance. Preparations may include cleaning the valve train components and inspecting them for any signs of wear or damage prior to installation.

Maintenance and Troubleshooting

Maintaining the AR45632 Valve Crosshead is key to ensuring its continued performance and longevity. Regular inspections for signs of wear, corrosion, or damage are recommended. Lubrication of moving parts, as per the manufacturer’s guidelines, can also help in maintaining smooth operation. Common issues that may arise include valve train noise, which could indicate misalignment or wear, and should be addressed promptly to prevent further damage. Troubleshooting steps may involve re-aligning components, replacing worn parts, or adjusting the valve clearance as necessary.

Performance Impact

The AR45632 Valve Crosshead affects engine performance in several ways. By ensuring precise valve operation, it contributes to improved fuel efficiency, as the engine can achieve more complete combustion. It also plays a role in enhancing power output by allowing the engine to operate at higher efficiencies. Additionally, proper valve train operation can lead to reduced emissions, as the engine burns fuel more cleanly and completely.

Compatibility and Applications

The AR45632 Valve Crosshead is designed for use in specific truck models and engine types, ensuring compatibility and optimal performance. Its applications span various operating environments, from long-haul trucking to construction and mining operations, where heavy-duty engines are prevalent. The crosshead’s robust design and material properties make it suitable for these demanding applications, contributing to the engine’s reliability and efficiency in diverse conditions.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer in the engine industry, known for its commitment to quality, innovation, and customer satisfaction. With a rich history of producing reliable and high-performance engines, Cummins has established a strong reputation for excellence. The company’s dedication to research and development ensures that its products, including the AR45632 Valve Crosshead, meet the highest standards of quality and performance, catering to the needs of heavy-duty applications across various industries.

Conclusion

The AR45632 Valve Crosshead is a critical component in the operation of heavy-duty truck engines, offering enhanced performance, reliability, and efficiency. Its robust design, precise engineering, and compatibility with specific engine models make it an essential part for maintaining the high standards of Cummins engines. Regular maintenance and proper installation are key to maximizing the benefits of this part, ensuring the longevity and optimal performance of the engine.

-

Daniel Williams, Generalized Vehicle Dynamics, SAE International, 2022.

↩ -

Giancarlo Genta and Lorenzo Morello, The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition, Springer, 2019.

↩ -

John C Dixon, Tyres Suspension and Handling Second Edition, SAE International, 1996.

↩ -

P. A. Lakshminarayanan and Avinash Kumar Agarwal, Design and Development of Heavy Duty Diesel Engines: A Handbook, Springer, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.