This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3032290 Valve Insert is a critical component for heavy-duty truck engines, ensuring the integrity of valve seats and contributing to efficient combustion processes. Understanding its function and importance is essential for maintaining and optimizing engine performance.

Basic Concepts of Valve Inserts

Valve inserts are components placed within the cylinder head of an engine to reinforce the valve seats. They withstand high temperatures and pressures generated during engine operation. By interacting with the valves, valve inserts help seal the combustion chamber, allowing for efficient fuel combustion and reducing the risk of valve seat wear 1.

Purpose of the 3032290 Valve Insert

This Cummins part is specifically engineered to maintain the integrity of the valve seats in Cummins engines. It ensures that the valve seats remain durable under the extreme conditions of high-performance engines. This component contributes to proper combustion by providing a stable and heat-resistant surface for the valves to seal against, which is vital for engine efficiency and longevity 2.

Key Features

The 3032290 Valve Insert is characterized by its robust material composition, typically made from high-strength alloys that offer superior heat resistance and durability. Its design includes precise dimensions to ensure a perfect fit within the cylinder head, enhancing the overall performance and reliability of the engine. Additionally, the insert may feature unique attributes such as enhanced heat dissipation properties, which contribute to its effectiveness in high-stress environments 3.

Benefits

Incorporating this part into an engine setup offers several advantages. It contributes to improved engine efficiency by ensuring optimal valve seat performance. The durability of the insert helps in reducing the frequency of maintenance required, while its reliable performance under high-stress conditions enhances the overall reliability of the engine 4.

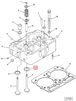

Installation Process

Installing the 3032290 Valve Insert requires careful attention to detail. The process involves preparing the cylinder head by cleaning and inspecting the valve seat area. Using appropriate tools, the insert is then pressed into place, ensuring it is seated correctly and flush with the cylinder head. It is important to follow manufacturer guidelines to ensure the insert is installed to the specified depth and alignment, which is critical for proper engine function.

Common Issues and Troubleshooting

Typical problems associated with valve inserts include wear, improper seating, and damage from high temperatures. Diagnosing these issues may involve visual inspection and performance testing. Troubleshooting steps can include re-seating the insert, replacing damaged components, or addressing issues with valve clearance and alignment to restore optimal engine performance.

Maintenance Tips

To prolong the lifespan of the 3032290 Valve Insert, routine maintenance practices are recommended. This includes regular inspections for signs of wear or damage, ensuring proper valve clearance, and addressing any issues promptly. Adhering to manufacturer-recommended maintenance intervals can help in identifying potential problems early, thereby extending the component’s service life and maintaining engine efficiency.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel engines and related components. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive industry. Their product range includes engines, filtration systems, and power generation equipment, catering to various sectors such as transportation, construction, and industrial applications.

Conclusion

The Cummins 3032290 Valve Insert plays a significant role in the performance and longevity of heavy-duty truck engines. By understanding its function, installation process, and maintenance requirements, engine efficiency and reliability can be optimized. Regular maintenance and adherence to manufacturer guidelines are key to ensuring the longevity and performance of this critical component.

-

Carroll, D. R. (2020). Energy Efficiency of Vehicles. SAE International.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Kershaw, J. F. (2023). SAE International’s Dictionary for Automotive Engineers. SAE International.

↩ -

Hilgers, M. (2023). Entire Vehicle: Second Edition. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.