This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

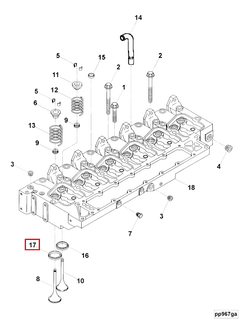

The Cummins 3925177 Valve Insert is a component designed for use in heavy-duty truck engines. It serves a specific function within the engine’s valve train system, contributing to the overall efficiency and reliability of the engine. Understanding its purpose and significance can provide valuable insights into engine maintenance and performance optimization.

Basic Concepts of Valve Inserts

Valve inserts are components installed within the cylinder head of an engine. They provide a durable surface for the valve seats, which are essential for the proper sealing of the combustion chamber. Valve inserts interact with both the valves and the valve seats, ensuring a secure and efficient seal during engine operation. This interaction is vital for maintaining engine performance and longevity 1.

Purpose of the 3925177 Valve Insert

The 3925177 Valve Insert plays a role in the operation of a truck engine by maintaining the integrity of the valve seat. It ensures that the valve seats remain in optimal condition, which is necessary for proper combustion and engine efficiency. By providing a robust surface for the valve to seal against, the insert helps in achieving consistent engine performance and reducing the wear on valve seats 2.

Key Features

The Cummins 3925177 Valve Insert is characterized by its specific design and material properties. It is crafted from high-quality materials that offer excellent resistance to wear and thermal stress. The design of the insert allows for precise fitting within the cylinder head, ensuring that it performs effectively under the demanding conditions of heavy-duty truck engines 3.

Benefits

Utilizing the 3925177 Valve Insert offers several advantages. It contributes to improved engine efficiency by ensuring a reliable seal between the valve and the seat. This results in reduced wear on valve seats and enhances the overall performance of the engine. Additionally, the durability of the insert means that it can withstand the high temperatures and pressures present in heavy-duty applications.

Installation Process

Installing the Cummins 3925177 Valve Insert requires careful attention to detail. The process involves preparing the cylinder head, ensuring the insert is correctly aligned, and securing it in place using appropriate tools. Following manufacturer guidelines during installation is important to ensure the insert fits correctly and functions as intended.

Troubleshooting Common Issues

Common issues with valve inserts may include leaks or improper seating. These problems can often be traced back to incorrect installation or wear on the insert. Troubleshooting methods may involve inspecting the insert for signs of damage, ensuring it is properly seated, and addressing any issues with the surrounding components to restore optimal engine performance.

Maintenance Tips

Regular maintenance of the Cummins 3925177 Valve Insert is important for prolonging its lifespan. This includes periodic inspections to check for signs of wear or damage. Maintaining the insert according to manufacturer recommendations can help prevent issues and ensure the engine continues to operate efficiently.

Cummins Corporation

Cummins Inc. is a well-established manufacturer in the heavy-duty truck industry, known for its wide range of engine and component products. The company has a reputation for producing high-quality, reliable parts that meet the demanding requirements of heavy-duty applications. Cummins’ commitment to innovation and customer satisfaction has made it a trusted name in the industry.

Valve Insert 3925177 Compatibility with Cummins Engines

The Valve Insert 3925177, manufactured by Cummins, is designed to be compatible with a range of Cummins engines, including the 4B3.9, 6B5.9, and B6.7S models. This part plays a role in ensuring the proper functioning of the engine’s valve system.

4B3.9 and 6B5.9 Engines

The 4B3.9 and 6B5.9 engines, both part of Cummins’ lineup, benefit from the precision engineering of the Valve Insert 3925177. This insert is engineered to fit seamlessly into the valve seats of these engines, providing a tight seal that is essential for maintaining optimal engine performance. The design ensures that the insert can withstand the high pressures and temperatures typical of these engines, contributing to their durability and efficiency.

B6.7S Engine

The B6.7S engine also integrates the Valve Insert 3925177 with ease. This engine, known for its robust performance, relies on the insert to maintain the integrity of its valve system. The insert’s compatibility with the B6.7S engine is particularly important in ensuring that the engine operates smoothly and efficiently, even under demanding conditions.

Grouping of Engines

The 4B3.9 and 6B5.9 engines, while distinct in their specifications, share a commonality in their use of the Valve Insert 3925177. This grouping highlights the versatility of the insert, which is designed to meet the specific needs of these engines. Similarly, the B6.7S engine, with its own set of requirements, also finds the insert to be an essential component in its operation.

The Valve Insert 3925177’s compatibility with these engines underscores its importance in maintaining the performance and longevity of Cummins’ engine lineup. Its design ensures that it can effectively integrate with the valve systems of the 4B3.9, 6B5.9, and B6.7S engines, providing a reliable solution for engine maintenance and repair.

Role of Part 3925177 Valve Insert in Engine Systems

The Part 3925177 Valve Insert is an integral component in the orchestration of various engine systems, ensuring optimal performance and efficiency. When integrated into the Cylinder Head, the Valve Insert facilitates the precise control of air and fuel mixture intake and exhaust, which is fundamental for combustion efficiency.

In a Cylinder Head Kit, the Valve Insert works in conjunction with other components to maintain the structural integrity and operational efficiency of the cylinder head. This kit often includes gaskets, seals, and other small parts that, together with the Valve Insert, ensure a leak-free and efficient operation of the cylinder head.

The interaction between the Valve Insert and the Fuel Pump Coupling is indirect but significant. Efficient valve operation, enabled by the Valve Insert, ensures that the engine runs smoothly, which in turn allows the fuel pump to deliver fuel at the correct pressure and timing.

In the context of the Head and Cylinder, the Valve Insert plays a role in maintaining the correct valve seat, which is essential for the sealing of the combustion chamber. This ensures that the air-fuel mixture is contained within the cylinder during combustion, maximizing power output and minimizing emissions.

When considering the NEF Cylinder and associated Kit, the Valve Insert is a key component that ensures the durability and reliability of the cylinder. It helps in withstanding the high temperatures and pressures generated during combustion, thus prolonging the lifespan of the cylinder.

Lastly, in relation to the Fuel Pump Conv, the Valve Insert contributes to the overall engine efficiency. By ensuring that the valves open and close at the correct times, it helps in optimizing the fuel delivery system’s performance, leading to better fuel economy and reduced emissions.

Conclusion

The Cummins 3925177 Valve Insert is a critical component in the maintenance and optimization of heavy-duty truck engines. Its role in ensuring the integrity of the valve seat, compatibility with various Cummins engines, and contribution to engine efficiency and durability make it an essential part for engine maintenance and repair. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Maclaurin, B. (2018). High Speed Off-Road Vehicles. Wiley.

↩ -

Arora, S., Abkenar, A. T., & Jayasi, S. G. (2021). Heavyduty Electric Vehicles: From Concept to Reality. Elsevier.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.