This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Valve Stem Guide 3904409, manufactured by Cummins, is designed for heavy-duty truck engines. This part ensures the proper function and alignment of the valve system, contributing to the engine’s reliability and performance 1.

Basic Concepts of Valve Stem Guides

A Valve Stem Guide is a cylindrical component that supports and guides the valve stem as it moves within the engine. It maintains the correct alignment of the valve, ensuring smooth and efficient operation. This guide helps prevent excessive wear on the valve and its components, enhancing the engine’s performance and longevity 2.

Purpose of the 3904409 Valve Stem Guide

The 3904409 Valve Stem Guide ensures the valve stem remains properly aligned during engine operation. This alignment is essential for maintaining the seal between the valve and the valve seat, which is crucial for efficient combustion and preventing the escape of combustion gases. Proper sealing contributes to the engine’s efficiency and performance 3.

Key Features of the 3904409 Valve Stem Guide

The 3904409 Valve Stem Guide is characterized by its durable construction and precision engineering. Made from high-quality materials resistant to wear and corrosion, it ensures long-lasting performance in heavy-duty truck engines. The guide’s design incorporates precise tolerances for a snug fit within the engine block, maintaining valve alignment. It is specifically engineered for compatibility with Cummins engines, ensuring optimal performance and reliability 4.

Benefits of Using the 3904409 Valve Stem Guide

Using the 3904409 Valve Stem Guide offers several advantages. Its durable construction and precise engineering contribute to improved engine efficiency by ensuring smooth valve operation and proper sealing. This results in reduced wear on valve components, enhancing overall engine performance and longevity. Additionally, its compatibility with Cummins engines ensures it meets the manufacturer’s stringent quality and performance standards.

Troubleshooting Common Issues with Valve Stem Guides

Common issues with Valve Stem Guides, including the 3904409 model, may include leaks, misalignment, and wear. Early identification of these problems can prevent significant engine damage. Leaks may indicate a failure in the seal between the valve and the valve seat, often due to misalignment or wear on the guide. Misalignment can be corrected by inspecting and, if necessary, replacing the guide. Wear on the guide may require replacement to restore proper valve operation.

Maintenance Tips for Valve Stem Guides

Regular maintenance of Valve Stem Guides is crucial for their longevity and optimal performance. This includes periodic inspection for signs of wear or damage, cleaning to remove any buildup that could affect performance, and replacement according to the manufacturer’s guidelines or when significant wear is observed. Proper maintenance extends the life of the Valve Stem Guide and contributes to the overall efficiency and reliability of the engine.

Cummins: A Brief Overview

Cummins Inc. is a global leader in designing, manufacturing, and distributing engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the automotive industry for producing reliable and high-performance engine components. The company’s commitment to quality and innovation is evident in its product offerings, including the 3904409 Valve Stem Guide, designed to meet the demanding requirements of heavy-duty applications.

Role of Part 3904409 Valve Stem Guide in Engine Systems

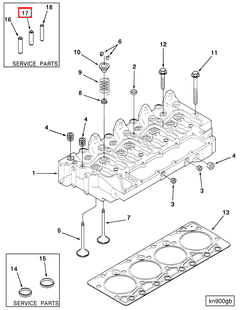

The Valve Stem Guide, identified by part number 3904409, is integral to the engine system, particularly within the cylinder head repair kit, set, and guide valve BS2.

In the context of a Cylinder Head Repair Kit, the Valve Stem Guide ensures the proper alignment and smooth operation of the valve within the cylinder head. This alignment is essential for maintaining the valve’s seal against the seat, ensuring efficient combustion and reducing the risk of valve train wear.

When examining the Set component, which typically includes various valve train elements, the Valve Stem Guide plays a supportive role by providing a precise pathway for the valve stem. This precision is vital for the consistent operation of the valve, contributing to the overall reliability and performance of the engine.

In relation to the Guide Valve BS2, the Valve Stem Guide works in tandem to maintain the structural integrity and operational efficiency of the valve system. The BS2 guide valve often requires a compatible stem guide to function correctly, ensuring that the valve stem moves without undue friction or misalignment, which could lead to premature wear or failure.

Overall, the Valve Stem Guide part 3904409 is a key element in maintaining the integrity and performance of the valve train system within the engine, directly influencing the engine’s efficiency and longevity.

Conclusion

The 3904409 Valve Stem Guide by Cummins is a critical component in heavy-duty truck engines, ensuring the proper alignment and operation of the valve system. Its durable construction, precision engineering, and compatibility with Cummins engines contribute to the engine’s efficiency, performance, and longevity. Regular maintenance and timely troubleshooting of common issues are essential for maximizing the benefits of this part.

-

The Motor Vehicle, TK Garrett, K Newton, W Steeds, Reed Educational and Professional Publishing Ltd, 2001.

↩ -

Automotive Technician Training Theory, Tom Denton and Hayley Pells, Routledge, 2022.

↩ -

Department of Energy Fundamentals Handbook, Department of Energy, 2015.

↩ -

SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, R. Matthew Brach, SAE Books, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.