This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3008786 Ventilation Tube is a component designed for use in commercial trucks. Its purpose is to facilitate proper ventilation within the engine or exhaust system. This part contributes to the efficient operation of the truck by ensuring that air flows correctly through the system, which is vital for maintaining engine performance and safety 2.

Basic Concepts of Ventilation Tubes

Ventilation tubes are components used in automotive systems to manage airflow. They play a role in maintaining pressure balance, preventing fluid accumulation, and ensuring that systems operate within their designed parameters. In heavy-duty trucks, these tubes contribute to overall performance and safety by allowing for the efficient exchange of air, which helps in cooling components and reducing the risk of system failures 1.

Purpose of the 3008786 Ventilation Tube

The 3008786 Ventilation Tube is specifically designed to play a role in the ventilation system of a truck. It functions by allowing air to circulate within the engine or exhaust system, which aids in temperature regulation and pressure management. This part ensures that the engine operates efficiently by maintaining optimal conditions within the system 2.

Key Features

The 3008786 Ventilation Tube is constructed from durable materials that can withstand the harsh conditions of a commercial truck environment. Its design includes features that enhance airflow and reduce the likelihood of blockages. The tube is engineered to fit precisely within the truck’s ventilation system, ensuring a secure and effective installation 3.

Benefits

The use of the 3008786 Ventilation Tube can lead to improved engine performance by ensuring that the ventilation system operates efficiently. This part contributes to the durability of the engine by helping to maintain optimal operating conditions. Additionally, by preventing issues that could lead to costly repairs, this tube can offer potential cost savings for fleet operators 2.

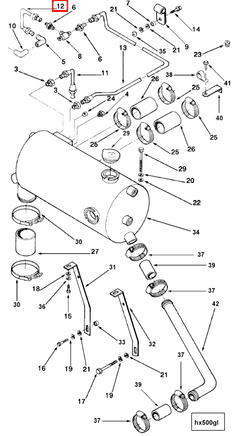

Installation Process

Installing the 3008786 Ventilation Tube requires careful attention to ensure a proper fit. The process involves locating the correct position within the ventilation system, securing the tube in place, and verifying that it is correctly aligned with other components. Tools such as wrenches and possibly a sealant may be required to complete the installation. Following manufacturer guidelines is recommended to ensure the tube is installed correctly 3.

Troubleshooting Common Issues

Common problems with ventilation tubes can include leaks or blockages. These issues can be identified by observing symptoms such as unusual noises from the engine or a decrease in performance. Troubleshooting steps may involve inspecting the tube for damage, ensuring it is securely fitted, and clearing any obstructions that may be present 1.

Maintenance Tips

Regular maintenance of the 3008786 Ventilation Tube is important for ensuring its longevity and optimal performance. This includes periodic inspections to check for signs of wear or damage, and cleaning the tube to remove any debris that may have accumulated. Adhering to recommended inspection intervals can help in identifying potential issues before they become more serious 2.

About Cummins

Cummins Inc. is a well-established company in the commercial truck industry, known for its range of engine and component products. With a history of innovation and quality, Cummins has built a reputation for providing reliable solutions that meet the demanding requirements of heavy-duty applications. The company’s product range includes a variety of parts designed to enhance the performance and efficiency of commercial vehicles 3.

Cummins Part 3008786: Ventilation Tube Compatibility with Cummins Engines

The Cummins part 3008786, a Ventilation Tube, is designed to integrate seamlessly with various Cummins engine models. This part plays a role in ensuring proper ventilation within the engine’s system, which is vital for maintaining optimal engine performance and longevity 3.

V28 Engines

The V28 engine series by Cummins is a robust and powerful engine line, often utilized in heavy-duty applications. The Ventilation Tube part 3008786 is specifically engineered to fit within the V28 engine architecture. Its design ensures that it can effectively manage airflow and pressure within the engine, preventing issues such as overheating and pressure buildup. This part is important in maintaining the engine’s efficiency and reliability, especially in demanding operational environments 3.

Group Compatibility

In addition to the V28 engines, the part 3008786 is also compatible with other Cummins engine groups that share similar design and operational requirements. This includes engines that are part of the same family or those that have been updated with similar ventilation systems. The compatibility ensures that the Ventilation Tube can be used across multiple models, providing a standardized solution for ventilation needs 3.

The integration of the part 3008786 into these engines is straightforward, thanks to its precise engineering and compatibility with Cummins’ design specifications. This ensures that the part fits snugly and functions as intended, contributing to the overall health and performance of the engine 3.

Role of Part 3008786 Ventilation Tube in Engine Systems

The Part 3008786 Ventilation Tube is a component in managing the pressure and fluid dynamics within various engine systems. It is specifically designed to interface with several key components to ensure optimal performance and safety 2.

Interaction with Heat Exchanger and Heat Exchanger Cooler

In systems equipped with a heat exchanger and heat exchanger cooler, the ventilation tube plays a role in regulating the pressure within these components. By allowing air to enter or exit the system as needed, it helps maintain a stable environment for efficient heat transfer. This is particularly important in high-performance engines where thermal management is key to longevity and efficiency 2.

Integration with Heat Exchanger

When integrated with a heat exchanger, the ventilation tube assists in preventing the buildup of excessive pressure that could lead to system failure. It ensures that the heat exchanger operates within its designed parameters, enhancing the overall cooling efficiency of the engine 2.

Function in Expansion Tank Systems

In systems that include an expansion tank, the ventilation tube is vital for managing the fluid levels and pressure within the tank. As the engine heats up, the coolant expands and is directed into the expansion tank. The ventilation tube allows air to escape from the tank as it fills, preventing over-pressurization. Conversely, when the engine cools down and the coolant contracts, the tube allows air to re-enter the tank, maintaining a balanced pressure and ensuring that the coolant can re-enter the engine system as needed 2.

Role in Vent Expansion Tank Tube and Vent Tube Applications

For applications involving a vent expansion tank tube or a general vent tube, the Part 3008786 ensures that any volatile gases or excess pressure are safely vented from the system. This is important for maintaining the integrity of the cooling system and preventing damage to sensitive components 2.

Conclusion

Overall, the Part 3008786 Ventilation Tube is a versatile component that enhances the functionality and reliability of various engine systems by ensuring proper pressure management and fluid dynamics. Its integration into Cummins engines, particularly the V28 series, underscores its importance in maintaining engine performance and longevity. Regular maintenance and proper installation are key to maximizing the benefits of this part 23.

-

Osgood, Libby, Gayla Cameron, and Emma Christensen. Engineering Mechanics: Statics. Creative Commons, 2024.

↩ ↩ -

Xin, Qianfan. Diesel Engine System Design. Woodhead Publishing Limited, 2011.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ -

Wright, Gus. Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning, 2015.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.