This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3426719 Vent Tube is a component designed for use in commercial trucks. Its purpose is to facilitate the venting of air or gases from fluid systems, ensuring that these systems operate efficiently and without interruption. The significance of the vent tube lies in its ability to maintain system integrity by preventing the buildup of pressure or vacuum conditions that could otherwise lead to system malfunctions.

Basic Concepts of Vent Tubes

A vent tube is a component used in fluid systems to allow the escape of air or gases. Its general function is to maintain a balanced pressure within the system, which is crucial for the proper operation of various components. By allowing air to escape, vent tubes help in preventing the formation of vacuums that could impede fluid flow or cause damage to system components. This contributes to maintaining system integrity and ensuring consistent performance 1.

Purpose of the 3426719 Vent Tube

The Cummins 3426719 Vent Tube plays a specific role in the operation of a truck, particularly within the fuel system. It allows for the venting of air or gases that may accumulate during the operation of the fuel system. This function is vital for maintaining the correct pressure within the system, which ensures efficient fuel delivery and prevents issues such as fuel starvation or system leaks.

Key Features

The Cummins 3426719 Vent Tube is characterized by several key features that enhance its performance. It is constructed from durable materials that can withstand the harsh conditions present in commercial truck environments. The design of the vent tube includes precise dimensions and fittings that ensure a secure and leak-free connection within the system. Additionally, it may feature unique characteristics such as filtration elements to prevent contamination from entering the system through the vent.

Benefits

The advantages provided by the Cummins 3426719 Vent Tube include improved system efficiency through the maintenance of correct pressure levels within the fuel system. It also reduces the risk of contamination by allowing only air or gases to escape, thereby protecting the system from external particles. Enhanced durability is another benefit, as the robust construction of the vent tube ensures long-term performance even under demanding conditions 2.

Installation Considerations

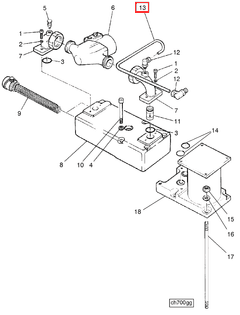

When installing the Cummins 3426719 Vent Tube, it is important to follow guidelines and best practices to ensure proper function. Necessary tools may include wrenches for securing connections and cleaning tools for preparing the installation site. Steps to follow include verifying the correct orientation of the vent tube, ensuring all connections are tight, and checking for any signs of leaks after installation. Common pitfalls to avoid include over-tightening connections, which can lead to damage, and neglecting to clean the installation site, which can introduce contaminants into the system.

Troubleshooting Common Issues

Common problems associated with vent tubes can include blockages, leaks, or contamination. Potential causes for these issues may be debris accumulation, wear and tear, or incorrect installation. Recommended troubleshooting steps include inspecting the vent tube for signs of damage or blockage, cleaning or replacing the vent tube if necessary, and ensuring all connections are secure and free from leaks.

Maintenance Tips

Routine maintenance practices for the Cummins 3426719 Vent Tube are important for ensuring longevity and optimal performance. Inspection intervals should be established based on the operating conditions and usage patterns of the truck. Cleaning procedures may involve flushing the vent tube with a compatible solvent to remove any accumulated contaminants. Regular checks for signs of wear or damage can help in identifying issues before they lead to system failures.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes engines, powertrains, and related components that are designed to meet the demanding requirements of commercial applications 3.

Role of 3426719 Vent Tube in Engine Systems

The 3426719 Vent Tube is an integral component in various engine systems, facilitating efficient operation and maintenance of engine performance.

In the Aid system, the Vent Tube allows for the release of pressure build-up, ensuring that the system operates within safe parameters. This is particularly important during the starting phase, where rapid changes in pressure can occur.

Within the Coolant Heater Starting system, the Vent Tube plays a role in managing the coolant flow. By venting excess pressure, it helps maintain a stable environment for the heater to function effectively, which is essential for cold-start conditions.

In the Assembly Preheater, the Vent Tube ensures that preheating processes do not lead to dangerous pressure levels. This is vital for the integrity of the preheater components and the overall efficiency of the preheating cycle.

For the Engine Assembly Heater, the Vent Tube is responsible for venting any excess pressure that may arise during the heating process. This helps in maintaining optimal conditions for the engine to start smoothly, especially in colder climates where preheating is necessary.

Overall, the 3426719 Vent Tube contributes to the safe and efficient operation of these engine systems by managing pressure and ensuring that components function within their designed parameters.

Conclusion

The Cummins 3426719 Vent Tube is a critical component in maintaining the efficiency and reliability of commercial truck fluid systems. Its role in pressure management, contamination prevention, and system integrity makes it an indispensable part of engine and fuel system operations. Proper installation, maintenance, and troubleshooting are essential to ensure the longevity and performance of this part.

-

Thorsten Boger, Willard Cutler, “Reducing Particulate Emissions in Gasoline Engines,” SAE International, 2018.

↩ -

Haoran Hu, Rudy Smaling, Simon Baseley, “Heavy-Duty Wheeled Vehicles,” SAE International, 2014.

↩ -

Allan Bonnick, “A Practical Approach to Motor Vehicle Engineering and Maintenance,” Elsevier, 2004.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.