This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Venturi Brace 3683523 is a component manufactured by Cummins, a well-established name in the commercial truck industry. This part is significant in the context of commercial truck operations due to its role in optimizing engine performance and efficiency.

Basic Concepts and Functionality

The Venturi effect is a fluid dynamics phenomenon where fluid speed increases as it flows through a constricted section of a pipe, resulting in a decrease in fluid pressure. The Venturi Brace applies this principle in its design and operation. By creating a constriction in the airflow path, it enhances the airflow dynamics around the engine, which can lead to improved engine efficiency 1.

Purpose of the Venturi Brace

The Venturi Brace plays a role in the operation of a truck by influencing airflow patterns. It is designed to direct and streamline the airflow over the engine, which can contribute to more efficient engine cooling and reduced aerodynamic drag. This, in turn, can lead to improvements in engine efficiency and overall truck performance 2.

Key Features

The Venturi Brace is characterized by its specific design, which incorporates the Venturi effect to optimize airflow. It is constructed from durable materials to withstand the rigors of commercial truck operations. Unique characteristics include its precise engineering to fit specific truck models and its ability to enhance engine performance through improved airflow management.

Benefits

The advantages of the Venturi Brace include improved fuel efficiency due to enhanced engine performance and reduced aerodynamic drag. Fleet operators may experience potential cost savings over time as a result of these efficiency improvements. Additionally, the part contributes to maintaining engine health by aiding in effective cooling 3.

Installation and Integration

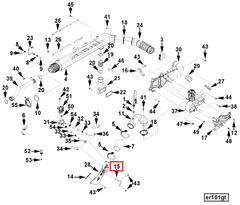

Proper installation of the Venturi Brace involves ensuring it is correctly positioned to achieve the desired airflow effects. It is important to follow manufacturer guidelines to integrate the brace into the truck’s system for optimal performance. Prerequisites may include assessing the existing airflow patterns and ensuring compatibility with the truck’s engine and chassis configuration.

Troubleshooting and Maintenance

Common issues with the Venturi Brace may include misalignment or damage, which can affect its performance. Regular inspections and maintenance are recommended to ensure longevity and optimal performance. Signs of wear or damage, such as cracks or deformations, should be addressed promptly to prevent further issues.

Performance Impact

The Venturi Brace has a noticeable impact on truck performance. It can lead to changes in fuel consumption by improving engine efficiency. Additionally, it may contribute to enhanced engine power and altered driving dynamics due to the optimized airflow it provides.

Compatibility and Usage

The Venturi Brace is designed for specific types of trucks and engines. It is most effective in configurations where improved airflow can significantly enhance engine performance and efficiency.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes engines, filtration systems, and other components designed to enhance the performance and efficiency of commercial vehicles.

Venturi Brace 3683523 in Cummins Engines

The Venturi Brace part number 3683523 is a critical component in several Cummins engine models, including the ISX CM871. This part plays a pivotal role in maintaining the structural integrity of the engine’s intake system, ensuring that the airflow dynamics are optimized for performance and efficiency.

In the ISX CM871 engine, the Venturi Brace is integral to the proper functioning of the intake manifold. It provides the necessary support to the intake manifold’s design, which is crucial for maintaining the correct shape and position of the intake tract. This ensures that the air-fuel mixture is delivered efficiently to the engine cylinders, which is essential for optimal combustion and power output.

The Venturi Brace is also used in other Cummins engine models where similar intake manifold designs are employed. Its design and placement are critical to the overall performance and longevity of the engine. By providing the required support and stability, the Venturi Brace helps in preventing any deformation or misalignment of the intake manifold, which could otherwise lead to performance issues and reduced engine efficiency.

In engines where the Venturi Brace is utilized, it is typically positioned in a manner that allows it to bear the stresses and strains associated with the intake system’s operation. This includes the forces generated by the airflow and the thermal expansion and contraction of the manifold materials. The precise engineering of the Venturi Brace ensures that it can withstand these forces without compromising the integrity of the intake system.

The use of the Venturi Brace in Cummins engines underscores the importance of each component in the overall design and functionality of the engine. By ensuring that the intake manifold remains in its optimal configuration, the Venturi Brace contributes to the engine’s ability to deliver consistent and reliable performance over time.

Venturi Brace Component Usage

The Venturi Brace, part 3683523, is integral to optimizing the performance of both recirculation and exhaust systems in engine applications.

In the context of recirculation systems, the Venturi Brace enhances the efficiency of air intake by creating a pressure differential. This differential allows for a more controlled and uniform flow of air into the engine, which is essential for maintaining optimal combustion conditions. The brace’s design facilitates a smoother transition of air through the recirculation pathways, reducing turbulence and ensuring that the air-fuel mixture is consistently delivered to the combustion chamber.

For exhaust systems, the Venturi Brace plays a significant role in managing the flow of exhaust gases. By leveraging the principles of fluid dynamics, the brace helps to maintain a steady pressure within the exhaust manifold. This stability is vital for reducing backpressure, which can otherwise impede engine performance. The Venturi Brace ensures that exhaust gases are expelled efficiently, contributing to better overall engine efficiency and reduced emissions.

In both applications, the Venturi Brace demonstrates its versatility and effectiveness in enhancing engine performance through precise control of airflow and exhaust management.

Conclusion

The Venturi Brace 3683523 by Cummins is a vital component in the optimization of engine performance and efficiency in commercial trucks. Through its application of the Venturi effect, this part enhances airflow dynamics, contributing to improved fuel efficiency, reduced aerodynamic drag, and effective engine cooling. Its precise engineering and durable construction ensure it can withstand the demands of commercial truck operations, making it a valuable asset for fleet operators seeking to maximize their vehicle’s performance and longevity.

-

Fehan, Douglas R. Design of Racing and High-Performance Engines 2004-2013. SAE International, 2013.

↩ -

Zhao, Hua. Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press, 2010.

↩ -

Rendle, Steve, and Martynn Randall. Haynes Diesel Engine Systems and Data Book. Haynes Publishing, 2000.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.