This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

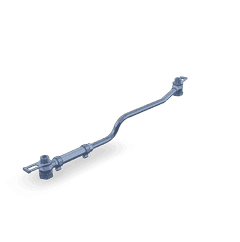

The Cummins 4899219 Vent Tube is a component designed to facilitate the proper functioning of commercial trucks. Its role is to ensure the efficient operation of the truck’s fluid systems by managing pressure and ventilation. Cummins, a well-established manufacturer in the industry, is known for producing reliable and high-quality parts that contribute to the performance and longevity of commercial vehicles 1.

Basic Concepts of Vent Tubes

A vent tube is a component used in fluid systems to allow air to enter or exit the system, thereby maintaining pressure equilibrium. This is vital for the efficient and safe operation of the system. The principles of pressure equalization and fluid dynamics are central to the function of vent tubes, as they help prevent issues such as fluid overflow and system malfunctions due to pressure imbalances 2.

Purpose of the 4899219 Vent Tube

The 4899219 Vent Tube plays a specific role in the operation of a truck by aiding in the maintenance of system pressure, preventing fluid overflow, and ensuring proper ventilation within the system. By allowing air to enter or exit the system as needed, it helps maintain a stable environment for the fluids, which is crucial for the overall efficiency and safety of the truck’s operations 3.

Key Features

The design and construction of the 4899219 Vent Tube incorporate features that enhance its performance and durability. The materials used in its construction are chosen for their ability to withstand the demands of commercial truck environments. Unique design elements may include specific shapes or connections that improve the tube’s functionality and integration within the truck’s system 4.

Benefits

Using the 4899219 Vent Tube in commercial truck applications offers several advantages. These include improved system reliability, as the vent tube helps maintain consistent pressure and ventilation. Enhanced safety is another benefit, as proper pressure management reduces the risk of system failures. Additionally, the vent tube may contribute to cost savings through reduced maintenance needs, as its design and materials are intended to provide long-lasting performance 5.

Installation Considerations

When installing the 4899219 Vent Tube, it is important to follow guidelines and best practices to ensure optimal performance. Proper placement and securing methods are crucial, as they affect the tube’s ability to function correctly within the system. Specific requirements may include ensuring the tube is correctly aligned and securely fastened to prevent leaks or disconnections 6.

Troubleshooting and Maintenance

Common issues associated with vent tubes can include blockages, leaks, or damage to the tube itself. Identifying these issues early can help maintain the efficiency and safety of the truck’s fluid systems. A step-by-step troubleshooting guide can assist in diagnosing problems, while regular maintenance tips can help prolong the life of the vent tube and ensure consistent performance 7.

Cummins as a Manufacturer

Cummins has a long-standing reputation in the commercial truck industry for producing high-quality parts. Their history and commitment to innovation have established them as a trusted manufacturer. Cummins’ product line includes a wide range of components designed to enhance the performance and reliability of commercial vehicles, reflecting their dedication to quality and customer satisfaction 8.

Vent Tube Part 4899219 in Cummins Engines

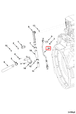

The Vent Tube part number 4899219, manufactured by Cummins, is a critical component in the ISB CM850 and ISBE CM800 engines. This part plays a pivotal role in maintaining the efficiency and reliability of these engines by ensuring proper ventilation within the engine’s system.

Application in ISB CM850

In the ISB CM850 engine, the Vent Tube part 4899219 is strategically positioned to facilitate the release of trapped air and gases. This helps in preventing pressure build-up that could potentially lead to system failures or reduced performance. The design and placement of this part are engineered to integrate seamlessly with the engine’s architecture, ensuring that it performs optimally under various operating conditions 9.

Application in ISBE CM800

Similarly, in the ISBE CM800 engine, the Vent Tube part 4899219 is integral to the engine’s ventilation system. Its primary function is to allow for the escape of air and gases, which is crucial for maintaining the integrity of the engine’s components. The part’s design ensures that it complements the engine’s overall structure, providing a reliable and efficient ventilation solution 10.

Common Functionality

Both the ISB CM850 and ISBE CM800 engines benefit from the Vent Tube part 4899219 in similar ways. By ensuring that trapped air and gases are vented out, this part helps in maintaining the engine’s operational efficiency and longevity. The integration of this component into the engine’s design underscores Cummins’ commitment to providing high-quality, reliable parts that enhance engine performance 11.

Role of Part 4899219 Vent Tube in Engine Systems

The part 4899219 Vent Tube is an essential component in maintaining the efficiency and reliability of engine systems. It is specifically designed to work in conjunction with the breather and crankcase components to ensure optimal engine performance.

Integration with the Breather System

In the breather system, the Vent Tube facilitates the release of pressure that builds up within the engine’s crankcase. As the engine operates, it generates gases and vapors that need to be expelled to prevent excessive pressure buildup. The Vent Tube provides a controlled pathway for these gases to escape, thereby maintaining a stable internal pressure. This function is vital for the proper operation of the breather system, which relies on consistent pressure levels to function effectively 12.

Interaction with the Crankcase

The crankcase is another area where the Vent Tube plays a significant role. The crankcase houses the crankshaft and connecting rods, and it is subject to the accumulation of gases and vapors produced during engine operation. The Vent Tube helps in venting these byproducts, ensuring that the crankcase remains free of excessive pressure. This not only protects the integrity of the crankcase but also contributes to the overall efficiency of the engine by allowing it to operate within its designed parameters 13.

Enhanced Engine Performance

By effectively managing pressure within the breather and crankcase, the Vent Tube contributes to smoother engine operation. It helps in reducing the risk of oil leaks and other issues that can arise from pressure buildup. Additionally, it aids in maintaining the cleanliness of the engine’s internal components by allowing contaminants to be expelled rather than circulating within the system 14.

Conclusion

In summary, the part 4899219 Vent Tube is a key component in the breather and crankcase systems, playing a vital role in pressure management and overall engine performance. Its proper function ensures that these systems operate efficiently, contributing to the longevity and reliability of the engine.

-

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩ -

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩ -

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩ -

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.