This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

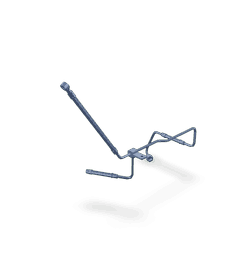

The Cummins Electronic Control Module Wiring Harness (5316796) is a critical component in the electrical system of heavy-duty trucks. It facilitates communication between the Electronic Control Module (ECM) and various truck systems, ensuring efficient vehicle operation. This wiring harness is essential for the truck’s performance, reliability, and functionality.

Basic Concepts

Electronic Control Module Wiring Harnesses, such as the 5316796, are designed to connect the ECM to other electrical components within the truck. They serve as conduits for signals and power, allowing the ECM to monitor and control various systems such as the engine, transmission, and emissions. The interaction between the wiring harness and the ECM is fundamental to the truck’s electrical system, enabling precise control and coordination of operations.

Purpose and Functionality

The 5316796 Wiring Harness plays a significant role in the operation of a truck by enabling seamless communication between the ECM and the truck’s systems. It transmits data and power to and from the ECM, allowing for real-time monitoring and adjustments. This ensures that the truck operates efficiently and responds accurately to driving conditions and commands.

Key Features

The 5316796 Wiring Harness is characterized by its robust design and high-quality materials, which contribute to its performance and durability. It is engineered to withstand the harsh conditions typical of heavy-duty truck environments. Unique attributes of this wiring harness include its precise engineering, which ensures reliable connections, and its resistance to wear and environmental factors, enhancing its longevity.

Benefits

The advantages of the 5316796 Wiring Harness include improved reliability and efficiency in the truck’s electrical system. Its design allows for easier installation compared to other wiring solutions, reducing downtime and labor costs. Additionally, the harness contributes to the overall efficiency of the truck by ensuring stable and consistent communication between the ECM and other systems.

Installation Process

Proper installation of the 5316796 Wiring Harness involves several steps to ensure it functions correctly. Begin by identifying the correct location for the harness within the truck’s electrical system. Follow the manufacturer’s guidelines for connecting the harness to the ECM and other components, ensuring all connections are secure and properly insulated. It is important to avoid common pitfalls such as improper routing of wires, which can lead to damage or interference.

Maintenance and Troubleshooting

Maintaining the 5316796 Wiring Harness involves regular inspections to check for signs of wear, corrosion, or damage. Common issues to watch for include loose connections and exposed wires. Troubleshooting steps may include verifying connections, testing for continuity, and replacing damaged sections as necessary. Adhering to a routine maintenance schedule can help prevent issues and ensure the harness continues to function effectively.

Cummins Overview

Cummins Inc. is a global leader in the design, manufacture, and distribution of diesel and alternative fuel engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a trusted provider of innovative solutions in the diesel engine and component manufacturing industry. The company’s commitment to innovation and quality is evident in its wide range of products, designed to meet the demanding requirements of various applications.

Cummins Electronic Control Module Wiring Harness 5316796 Compatibility

The Cummins Electronic Control Module (ECM) Wiring Harness part number 5316796 is designed to integrate seamlessly with a range of Cummins engines, ensuring reliable and efficient electrical connectivity. This wiring harness is crucial for the proper functioning of the ECM, which manages various engine operations and diagnostics.

QSL9 Engines

The QSL9 series engines benefit from the 5316796 wiring harness, which provides the necessary electrical pathways for the ECM to communicate with other engine components. This harness ensures that the ECM can effectively monitor and control engine performance, emissions, and diagnostics.

CM2350 Engines

For the CM2350 engines, the 5316796 wiring harness is engineered to fit precisely, facilitating smooth and uninterrupted communication between the ECM and the engine’s various systems. This compatibility is essential for maintaining optimal engine performance and ensuring that the ECM can accurately manage fuel injection, ignition timing, and other critical functions.

L102 Engines

The L102 engines also utilize the 5316796 wiring harness, which is designed to meet the specific electrical requirements of these engines. This harness ensures that the ECM can effectively manage engine operations, including fuel delivery, ignition timing, and emissions control, thereby enhancing overall engine efficiency and reliability.

By providing a robust and reliable connection, the 5316796 wiring harness ensures that the ECM can perform its critical functions without interruption, contributing to the overall performance and longevity of the engines it supports.

Role of Part 5316796 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness (part 5316796) is integral to the operation of various engine systems, ensuring seamless communication and power distribution between the ECM and other components.

In the context of the vent system, the ECM Wiring Harness facilitates the connection between the ECM and the vent solenoids. This allows the ECM to control the opening and closing of the vent valves, which is essential for maintaining the correct pressure within the fuel tank. Proper venting prevents fuel vapor buildup, which could otherwise lead to issues such as fuel system leaks or decreased engine performance.

Regarding the engine coolant system, the ECM Wiring Harness plays a significant role by linking the ECM to the coolant temperature sensor and the coolant fan control module. This connection enables the ECM to monitor the engine’s temperature in real-time. Based on the sensor data, the ECM can adjust the operation of the coolant fan to ensure the engine maintains optimal temperature, thereby preventing overheating and ensuring efficient engine operation.

Overall, the ECM Wiring Harness is a fundamental component that enhances the functionality and reliability of these engine systems by providing the necessary electrical pathways for control and monitoring.

Conclusion

The Cummins Electronic Control Module Wiring Harness (5316796) is a vital component in the electrical system of heavy-duty trucks, ensuring efficient communication between the ECM and various truck systems. Its robust design, ease of installation, and compatibility with a range of Cummins engines make it an essential part for maintaining optimal engine performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.