This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3043637 Lock Washer is a specialized component designed for use in commercial trucks. Its primary function is to enhance the security of fastening systems, ensuring that bolts and nuts remain tightly fastened under various operating conditions. This lock washer is particularly important in the maintenance and operation of commercial trucks, where secure fastening is essential for safety and efficiency.

Basic Concepts of Lock Washers

Lock washers are mechanical devices used in fastening systems to prevent loosening of bolts and nuts. They operate by creating additional friction or by deforming under load, which helps to keep the fastener in place. Lock washers come in various designs, including split lock washers, which have a gap that creates tension when the washer is compressed, and serrated lock washers, which have teeth that dig into the mating surfaces to increase friction 1.

Purpose of the Cummins 3043637 Lock Washer

The Cummins 3043637 Lock Washer plays a specific role in the fastening systems of commercial trucks. It is designed to ensure that bolts and nuts remain securely fastened, even under the dynamic and often harsh conditions encountered in truck operations. By preventing loosening, this lock washer helps maintain the integrity of critical truck components, contributing to overall vehicle safety and performance.

Key Features

The Cummins 3043637 Lock Washer is characterized by several distinctive features that enhance its performance. It is typically made from high-strength steel, ensuring durability and resistance to wear. The design of the washer includes specific serrations or splits that provide additional friction and tension, effectively preventing loosening. Additionally, the washer is coated to resist corrosion, making it suitable for use in various environmental conditions.

Benefits of Using the Cummins 3043637 Lock Washer

Using the Cummins 3043637 Lock Washer offers several advantages. It provides improved fastening security, ensuring that bolts and nuts remain tightly fastened even under vibration and dynamic loads. The washer’s resistance to corrosion extends its lifespan, making it suitable for long-term use in commercial trucks. Additionally, its design helps to distribute loads more evenly, reducing the risk of damage to mating surfaces 2.

Installation Guidelines

Proper installation of the Cummins 3043637 Lock Washer is crucial for its effective performance. To install, place the lock washer under the nut or bolt head, ensuring that the serrations or splits are correctly oriented to create tension. Tighten the fastener to the manufacturer’s specified torque, avoiding over-tightening, which can damage the washer or the mating surfaces. Common mistakes to avoid include incorrect orientation of the washer and using damaged or deformed washers.

Troubleshooting and Maintenance

Identifying issues related to lock washers, such as loosening or damage, is important for maintaining optimal performance. Regular inspections should be conducted to check for signs of wear or corrosion. If a lock washer appears damaged or shows signs of loosening, it should be replaced promptly. Maintenance practices, such as keeping fastening systems clean and free of debris, can also help ensure the longevity and effectiveness of the lock washers 3.

Common Applications in Commercial Trucks

The Cummins 3043637 Lock Washer is commonly used in various components and systems within commercial trucks. Typical applications include securing engine mounts, transmission components, and chassis parts. It is also used in braking systems and suspension components, where secure fastening is critical for safety and performance.

Manufacturer Information - Cummins

Cummins Inc. is a renowned manufacturer with a long-standing reputation in the automotive and heavy-duty truck industries. Founded in 1919, Cummins has built a legacy of quality, innovation, and reliability. The company is committed to producing high-performance components that meet the demanding requirements of commercial vehicles. Cummins’ dedication to research and development ensures that their products, including the 3043637 Lock Washer, deliver exceptional performance and durability.

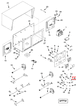

Lock Washer 3043637 in Cummins Engines

The Lock Washer 3043637, manufactured by Cummins, is a critical component in several of their engine models. This part is designed to secure fasteners in place, preventing loosening due to vibration or torque. Here’s how it integrates with various Cummins engines:

K19, K38, K50 Engines

In the K19, K38, and K50 engines, the Lock Washer 3043637 is used to ensure the integrity of bolted connections. These engines, known for their robust performance, require reliable fastening solutions to maintain operational safety and efficiency. The washer’s design helps maintain the tension of the bolts, which is crucial for the longevity and reliability of the engine components.

N14 MECHANICAL Engine

The N14 MECHANICAL engine also benefits from the Lock Washer 3043637. This engine, favored for its durability and power, relies on precise fastening to handle high stress and torque. The lock washer ensures that bolts remain tight, reducing the risk of failure under demanding conditions.

NH/NT 855 Engines

For the NH/NT 855 engines, the Lock Washer 3043637 plays a vital role in maintaining the structural integrity of the engine. These engines are designed for heavy-duty applications, and the washer’s ability to prevent loosening is essential for consistent performance and safety.

V28 Engine

The V28 engine incorporates the Lock Washer 3043637 to secure various components, ensuring that the fasteners do not come loose due to the engine’s operational stresses. This engine’s design demands reliable fastening solutions, and the lock washer provides the necessary security.

By using the Lock Washer 3043637, Cummins ensures that their engines maintain the highest standards of reliability and performance, safeguarding critical connections across different engine models.

Role of Part 3043637 Lock Washer in Engine Systems

In the intricate assembly of engine systems, the part 3043637 Lock Washer serves as a vital component ensuring the stability and integrity of various connections. When integrated with the Generator Control Panel, the Lock Washer secures the electrical connections, preventing any unwanted loosening that could lead to intermittent power supply or system failure. This is particularly important in maintaining consistent generator performance and reliability.

In conjunction with the MTG (Main Terminal Gear), the Lock Washer plays a significant role in securing the terminal connections. This ensures that the electrical pathways remain intact under varying operational conditions, thus enhancing the overall efficiency and safety of the engine system.

Furthermore, when used with the Synchronizing Resistor, the Lock Washer helps in maintaining the precise electrical resistance required for synchronizing the engine with the grid or other power sources. This is essential for preventing phase shifts and ensuring smooth operation during load changes or system startups.

Overall, the part 3043637 Lock Washer is instrumental in enhancing the durability and reliability of these engine components by providing the necessary mechanical stability to the electrical and mechanical connections.

Conclusion

The Cummins 3043637 Lock Washer is a critical component in the fastening systems of commercial trucks and Cummins engines. Its design and features ensure secure fastening under dynamic conditions, contributing to the safety, efficiency, and reliability of vehicle operations. Proper installation, regular maintenance, and understanding its applications are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.