This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3059972 Plain Washer is a component designed for use in commercial truck operations. It serves a specific function within the mechanical systems of trucks, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance can enhance the maintenance and operational practices of truck fleets.

Basic Concepts of Plain Washers

Plain washers are simple yet vital components in mechanical systems. They are typically flat, annular metal rings that distribute load, prevent damage to surfaces, and maintain the proper spacing between parts. In operation, plain washers help to evenly distribute the force exerted by a fastener, such as a bolt or screw, across a larger surface area, thereby reducing the risk of damage to the materials being joined 1.

Purpose of the Cummins 3059972 Plain Washer

The Cummins 3059972 Plain Washer is specifically engineered to play a role in the fastening systems of trucks. It is applied in various truck components where secure and durable connections are required. This washer ensures that the load from fasteners is evenly distributed, which is particularly important in heavy-duty applications where stress and vibration are common 2.

Key Features

The Cummins 3059972 Plain Washer is characterized by several key features that make it suitable for heavy-duty applications. It is typically made from high-strength materials to withstand the rigors of truck operations. Its dimensions are precisely engineered to fit specific applications, ensuring a secure and reliable connection. The design of the washer also considers factors such as corrosion resistance and ease of installation 3.

Benefits of Using Cummins 3059972 Plain Washer

Utilizing the Cummins 3059972 Plain Washer offers several advantages in truck maintenance and operation. Its durability ensures long-term performance under demanding conditions. The reliability of the washer contributes to the overall stability of truck components, reducing the likelihood of failures. Additionally, the washer enhances the performance of fastening systems by providing consistent load distribution and protection against wear 4.

Installation and Usage

Proper installation of the Cummins 3059972 Plain Washer is crucial for its effective function. It should be placed under the head of a bolt or nut to ensure even load distribution. Best practices include using the correct size washer for the application and ensuring that it is not damaged during installation. Common applications within truck maintenance include use in engine components, chassis parts, and other areas where secure fastening is required.

Troubleshooting and Maintenance

Regular maintenance and inspection of plain washers can help identify potential issues before they lead to failures. Common problems may include wear, corrosion, or improper installation. Maintenance tips include checking for signs of damage or deformation and replacing washers as necessary to maintain the integrity of fastening systems. Identifying when a replacement is needed involves looking for changes in performance or visible signs of wear.

Manufacturer Information - Cummins

Cummins is a well-regarded manufacturer in the automotive and heavy-duty truck industries. The company is known for its commitment to quality and innovation in the production of automotive components. Cummins components, including the 3059972 Plain Washer, are designed with precision and durability in mind, reflecting the brand’s reputation for excellence in the industry.

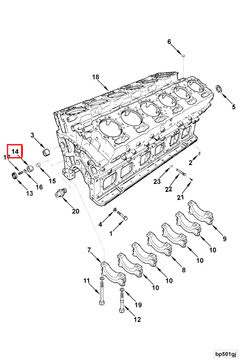

Cummins Part 3059972: Plain Washer Application in V28 Engines

The Cummins part 3059972, a Plain Washer, is a critical component in the V28 engine series. This part is designed to provide a smooth and even surface for sealing and to prevent leaks in various engine applications. Its role is vital in maintaining the integrity of engine connections and ensuring operational efficiency.

In the V28 engine, the Plain Washer is typically used in conjunction with bolts and nuts to create a secure seal. The washer’s material and design ensure it can withstand the high pressures and temperatures encountered within the engine. This reliability is essential for the longevity and performance of the engine.

The Plain Washer is often found in areas where precise alignment and pressure are required, such as in the engine block, cylinder head, and other critical junctions. Its placement is crucial for preventing any potential fluid or gas leaks, which could otherwise lead to engine damage or reduced performance.

In the V28 engine, the Plain Washer is part of a broader system of components that work together to maintain the engine’s structural integrity and operational efficiency. Its application is consistent across various engine models within the V28 series, highlighting its versatility and importance in engine assembly.

Role of Part 3059972 Plain Washer in Engine Systems

The part 3059972 Plain Washer is an essential component in various engine systems, contributing to the functionality and efficiency of several key assemblies.

In the Base Parts of an engine, this washer is often used to provide a smooth surface between mating components, reducing friction and wear. It ensures that parts fit together precisely, which is vital for the overall performance and longevity of the engine.

Within the Cylinder Block, the plain washer plays a role in maintaining the integrity of the block’s internal components. It is commonly placed between the cylinder block and other attached parts, such as sensors or mounting brackets, to prevent direct metal-to-metal contact, which could lead to galling or seizing.

In a Cylinder Block Kit, which includes various gaskets, seals, and hardware necessary for rebuilding a cylinder block, the plain washer is used to ensure proper spacing and alignment during reassembly. This helps in achieving the correct compression ratios and sealing surfaces.

For the Cylinder Short Block and Cylinder Short V-12 Block, the washer is instrumental in the assembly process. It is placed in critical junctions where components like the crankshaft, pistons, and connecting rods interface with the block, ensuring smooth operation and preventing undue stress on the parts.

In the Cylinder V-12 Block, given its complexity with multiple cylinders arranged in a V-configuration, the plain washer assists in maintaining the precise alignment of components. This is particularly important in high-performance engines where even minor misalignments can lead to significant issues.

The Service Cylinder Block, which is often used in repair and maintenance scenarios, relies on the plain washer to restore the original fit and function of replaced or repaired parts. It helps in recalibrating the engine to its factory specifications.

In the Short Block Cylinder and Short Block Engine Kit, the washer is a small yet significant part that ensures all components within the short block—which typically includes the crankshaft, pistons, and rods—are correctly spaced and aligned. This is essential for the balanced operation of the engine.

Lastly, in the Subbase of an engine, which supports the cylinder block and other critical components, the plain washer is used to distribute loads evenly and prevent direct contact between dissimilar metals, which could lead to corrosion or other forms of degradation.

Overall, the part 3059972 Plain Washer, though small, plays a vital role in the assembly, maintenance, and operation of various engine systems, ensuring that components work together seamlessly and efficiently.

Conclusion

The Cummins 3059972 Plain Washer is a critical component in the maintenance and operation of commercial trucks and engines. Its role in distributing load, preventing damage, and ensuring proper spacing between parts is essential for the reliability and efficiency of truck fleets. Proper installation, regular maintenance, and understanding its application in various engine systems are key to maximizing the benefits of this Cummins part.

-

Trzesniowski, Michael. The Complete Vehicle. Springer Nature, 2023.

↩ -

Wharton, A. J. Diesel Engines. Butterworth-Heinemann Ltd, 1991.

↩ -

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩ -

Arora, Shashank, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi. Heavyduty Electric Vehicles: From Concept to Reality. Elsevier, 2021.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.