3093778

Plain Washer

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3093778 Plain Washer is a component designed for use in commercial truck operations. It serves a specific function within the mechanical assemblies of these vehicles, contributing to the overall efficiency and reliability of truck performance.

Basic Concepts of Plain Washers

Plain washers are simple yet vital components in mechanical systems. They are typically flat, annular devices made from metal or other materials. Their general function is to distribute loads, prevent damage to surfaces, and provide a smooth bearing surface. In operation, plain washers help to evenly distribute the force exerted by fasteners, such as bolts and nuts, across a larger area, reducing the risk of damage to the materials they are securing 1.

Purpose of the Cummins 3093778 Plain Washer

The Cummins 3093778 Plain Washer plays a role in truck operations by providing a stable and even distribution of load where it is installed. It is part of an assembly that requires precise load distribution to function correctly. This washer ensures that the forces exerted by fastening elements are spread evenly, which helps in maintaining the integrity of the assembly and the overall performance of the truck.

Key Features

The Cummins 3093778 Plain Washer is characterized by several key features that make it suitable for heavy-duty applications. It is constructed from materials that offer durability and resistance to wear. Its dimensions are precisely engineered to fit within specific assemblies, ensuring optimal performance. The design of this washer also takes into account the need for it to withstand high loads and operate in demanding environments typical of commercial truck use.

Benefits of Using Plain Washers

Incorporating plain washers into truck assemblies offers several advantages. They aid in the even distribution of loads, which can help prevent damage to connected parts. Plain washers also contribute to vibration damping, which is crucial in reducing the wear and tear on mechanical components. Additionally, they help prevent galling, a form of surface damage that can occur when two metal surfaces rub against each other under pressure 2.

Installation Considerations

Proper installation of the Cummins 3093778 Plain Washer is important for ensuring optimal performance and longevity. It should be installed according to manufacturer specifications, which may include torque settings for associated fasteners. Best practices for installation involve ensuring that the washer is correctly aligned and seated, and that it is free from contaminants that could affect its function.

Troubleshooting Common Issues

Common problems associated with plain washers can include wear and tear or an improper fit within an assembly. If a washer shows signs of excessive wear, it may need to be replaced. An improper fit can lead to inefficient load distribution and should be addressed by ensuring the correct washer is used for the application.

Maintenance Tips

Regular maintenance of plain washers is important for ensuring continued reliable operation. This includes periodic inspection for signs of wear or damage. Replacement guidelines should be followed to ensure that worn washers are replaced before they can cause issues within the assembly they are part of.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its range of diesel engines and related technologies. With a history of innovation and quality, Cummins has built a reputation for producing reliable and high-performance components, including the Cummins 3093778 Plain Washer, which is designed to meet the rigorous demands of commercial truck operations.

Cummins Engine Compatibility with Part 3093778

The Plain Washer part number 3093778, manufactured by Cummins, is a versatile component that fits into various Cummins engine models. This part is essential for ensuring proper sealing and alignment in the engine assembly. Below is a detailed description of its compatibility across different engine series:

Cummins 4 Series Engines

- 4B3.9

- 6B5.9

The Plain Washer 3093778 is compatible with the 4B3.9 and 6B5.9 engines, providing a crucial sealing function that helps maintain the integrity of the engine’s internal components.

Cummins 6 Series Engines

- 6C8.3

- C8.3 G

- QSC8.3 CM554

- QSC8.3 CM850 (CM2850)

This washer is also suitable for the 6C8.3, C8.3 G, QSC8.3 CM554, and QSC8.3 CM850 (CM2850) engines, ensuring that the engine’s various parts are properly aligned and sealed.

Cummins ISC Series Engines

- ISC CM2150

- ISL CM2150

The Plain Washer 3093778 fits into the ISC CM2150 and ISL CM2150 engines, contributing to the engine’s overall performance by maintaining the correct spacing and sealing between parts.

Cummins QSB Series Engines

- QSB4.5 CM2250 EC

- QSB4.5 CM850 (CM2850)

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSB6.7 CM850 (CM2850)

- QSB7 CM2880 B117

This washer is compatible with the QSB4.5 CM2250 EC, QSB4.5 CM850 (CM2850), QSB6.7 CM2250, QSB6.7 CM2350 B105, QSB6.7 CM850 (CM2850), and QSB7 CM2880 B117 engines, ensuring proper alignment and sealing in these high-performance engines.

Cummins QSC Series Engines

- QSC8.3 CM554

- QSC8.3 CM850 (CM2850)

The Plain Washer 3093778 fits into the QSC8.3 CM554 and QSC8.3 CM850 (CM2850) engines, providing essential sealing and alignment functions.

Cummins QSL Series Engines

- QSL9 CM554

- QSL9 CM850 (CM2850)

This washer is also compatible with the QSL9 CM554 and QSL9 CM850 (CM2850) engines, ensuring the engine’s components are properly sealed and aligned.

Cummins QST Series Engines

- QST30 CM2350 T101

- QST30 CM552

The Plain Washer 3093778 fits into the QST30 CM2350 T101 and QST30 CM552 engines, contributing to the engine’s performance by maintaining the correct spacing and sealing between parts.

By understanding the compatibility of the Plain Washer 3093778 across these various Cummins engine models, technicians and engine operators can ensure that their engines are properly maintained and performing optimally.

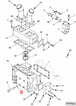

Role of Part 3093778 Plain Washer in Engine Systems

The part 3093778 Plain Washer is a versatile component utilized across various engine systems to ensure smooth operation and efficient performance. Its applications span multiple critical areas within the engine, contributing to the overall functionality and reliability of the system.

Adjusting Link

In the adjusting link mechanism, the Plain Washer helps maintain proper tension and alignment. It ensures that the link operates within specified tolerances, reducing wear and tear on connected components.

Alternator Bracket

When installed in the alternator bracket, the Plain Washer provides a smooth surface for the alternator to pivot on. This reduces friction and allows for efficient power generation without unnecessary strain on the bracket or alternator.

Arrangement - Lifting and Vibration Damper

In lifting arrangements and vibration dampers, the Plain Washer acts as a spacer, maintaining the correct distance between components. This is essential for the effective operation of the damper, which mitigates vibrations transmitted through the engine.

Breather - Crankcase

Within the crankcase breather system, the Plain Washer ensures a secure fit of the breather components. It helps in maintaining the integrity of the seal, which is vital for preventing oil leaks and maintaining proper crankcase pressure.

Compressor - Refrigerant

In refrigerant compressors, the Plain Washer is used to ensure that the compressor components are properly aligned. This alignment is key to the efficient compression of refrigerant, which is critical for the cooling system’s performance.

Connection - Air Transfer, Water Inlet, and Water Outlet

For air transfer, water inlet, and water outlet connections, the Plain Washer provides a smooth transition between fittings. This ensures that there are no leaks and that the flow of air or water is uninterrupted, which is essential for engine cooling and air management systems.

Damper - Vibration

In vibration dampers, the Plain Washer helps in maintaining the correct spacing between the damper and other engine components. This ensures that the damper can effectively absorb vibrations, leading to a smoother engine operation.

Drive - Front and Rear Gear Train Accessory

For both front and rear gear train accessories, the Plain Washer ensures that the drive components are properly spaced and aligned. This is important for the efficient transfer of power from the engine to the accessories.

Engine Control Module

In the engine control module (ECM) mounting, the Plain Washer provides a stable platform for the ECM. This ensures that the ECM remains securely in place, which is vital for its accurate monitoring and control of engine functions.

Flywheel Housing

Within the flywheel housing, the Plain Washer helps in maintaining the correct clearance between the flywheel and housing. This is important for the smooth operation of the flywheel and the prevention of undue wear.

Front Engine Support

In the front engine support system, the Plain Washer ensures that the engine is properly aligned and supported. This is crucial for the overall stability and performance of the engine.

Fuel Filter

For the fuel filter, the Plain Washer ensures a secure fit within the fuel plumbing system. This is important for maintaining the integrity of the fuel line and ensuring a consistent fuel supply to the engine.

Guard - Front Engine

In the front engine guard, the Plain Washer helps in securing the guard in place. This ensures that the guard effectively protects the engine from debris and other potential hazards.

Harness - Electronic Control Module Wiring

In the electronic control module wiring harness, the Plain Washer ensures that the wiring is properly spaced and protected. This is vital for the reliable transmission of electrical signals within the engine system.

Mounting - Air Cleaner

For the air cleaner mounting, the Plain Washer ensures a secure and vibration-free fit. This is important for the efficient operation of the air cleaner and the maintenance of clean air intake for the engine.

Plumbing - Fuel

In fuel plumbing systems, the Plain Washer ensures that connections are tight and leak-free. This is essential for the safe and efficient transfer of fuel within the engine system.

Rail - Base

On the base rail, the Plain Washer provides a smooth surface for other components to mount on. This ensures that the base rail can support the weight and vibrations of the engine effectively.

Support - Front Engine

In front engine support systems, the Plain Washer helps in maintaining the correct alignment and spacing of support components. This is important for the overall stability and performance of the engine.

System - Engine Monitoring

Within engine monitoring systems, the Plain Washer ensures that sensors and other components are properly aligned and spaced. This is vital for the accurate monitoring of engine parameters and the reliable operation of the engine.

Turbocharger Kit

In turbocharger kits, the Plain Washer ensures that turbocharger components are properly aligned and spaced. This is important for the efficient operation of the turbocharger and the overall performance of the engine.

Water Inlet Connection

For water inlet connections, the Plain Washer ensures a smooth and leak-free fit. This is essential for the efficient transfer of coolant into the engine, which is vital for maintaining optimal engine temperature.

Conclusion

The Cummins 3093778 Plain Washer is a critical component in the maintenance and operation of commercial trucks and various Cummins engine models. Its role in distributing loads, preventing damage, and ensuring proper alignment and sealing across multiple engine systems underscores its importance in achieving optimal engine performance and reliability. Proper installation, regular maintenance, and understanding its compatibility with different engine models are essential for leveraging the full benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.