This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

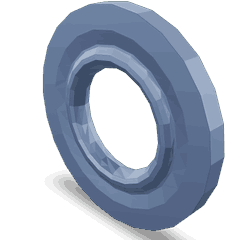

The Cummins 3336396 Sealing Washer is a critical component designed to maintain the integrity of fluid systems in commercial trucks. It ensures the prevention of leaks and maintains system pressure by creating a tight seal between mating surfaces. Sealing washers, in general, are small, often circular components used in mechanical systems to prevent fluid or gas leakage at joints and connections 1.

Basic Concepts of Sealing Washers

Sealing washers are engineered to fit snugly between two surfaces to prevent the escape of fluids or gases. They are typically made from materials such as rubber, metal, or composite materials, chosen for their durability and resistance to the specific fluids they will encounter. The principle of operation involves compressing the washer between two surfaces, which creates a seal that prevents leakage and maintains system integrity 2.

Purpose of the 3336396 Sealing Washer

The 3336396 Sealing Washer plays a specific role in the operation of commercial trucks by ensuring the sealing of fluid systems. It is associated with various components such as fuel injectors, where it helps maintain the pressure necessary for proper fuel delivery. By preventing leaks, it contributes to the efficient operation of these systems 3.

Key Features

This Cummins part is characterized by its material composition, typically a durable elastomer that can withstand high pressures and temperatures. Its design includes precise dimensions to ensure a proper fit and effective seal. Unique characteristics may include resistance to specific chemicals or enhanced flexibility for better sealing performance.

Benefits

Using the 3336396 Sealing Washer offers several benefits, including improved system reliability through effective leak prevention. It enhances the performance of fluid systems by maintaining consistent pressure and flow. Additionally, its durability contributes to the longevity of the components it seals, which in turn supports the overall efficiency and safety of the truck.

Installation and Usage

Proper installation of the 3336396 Sealing Washer involves ensuring it is correctly positioned between the mating surfaces without damage. It is used under conditions where fluid or gas sealing is required, and specific application requirements may include the use of lubricants to facilitate installation and ensure a proper seal.

Troubleshooting and Maintenance

Common issues with the 3336396 Sealing Washer may include wear or deformation leading to leaks. Regular inspection for signs of damage or deterioration is recommended. Maintenance tips include replacing the washer at recommended intervals or upon signs of wear to ensure continued system integrity and performance.

Compatibility and Applications

The 3336396 Sealing Washer is designed for use in specific truck models and systems, ensuring compatibility with the components it is intended to seal. Its applications vary across different commercial truck configurations, providing a reliable sealing solution for a range of fluid systems.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of high-quality automotive components. With a history of innovation and commitment to quality, Cummins products are designed to meet the demanding requirements of commercial vehicle applications, ensuring reliability and performance in various operating conditions.

Cummins Sealing Washer 3336396 Compatibility

The Cummins Sealing Washer part number 3336396 is designed to fit a variety of Cummins engines, ensuring a secure seal in critical areas where fluid or gas leakage could occur. This part is essential for maintaining the integrity of engine systems and preventing operational failures.

KTA38GC CM558 Engines

The KTA38GC CM558 engines benefit from the use of the 3336396 sealing washer in various components, including fuel injectors and other fluid pathways. This washer ensures that the engine operates efficiently by preventing leaks that could compromise performance.

QSV81G and QSV91-G4 CM558/CM700 V102 Engines

For the QSV81G and QSV91-G4 CM558/CM700 V102 engines, the 3336396 sealing washer is integral to the operation of several high-pressure systems. Its use in these engines helps maintain the required pressure levels and ensures that the engine runs smoothly without any leakage issues.

QSV91G Engines

In the QSV91G engines, the 3336396 sealing washer is utilized in key areas to prevent fluid and gas leaks. This part is crucial for maintaining the engine’s operational efficiency and reliability.

QSW/QSV82 Engines

The QSW/QSV82 engines also incorporate the 3336396 sealing washer in various components. This washer helps to maintain the integrity of the engine by preventing leaks that could lead to performance issues.

QSW27, QSW36, and QSW73 Engines

For the QSW27, QSW36, and QSW73 engines, the 3336396 sealing washer is used in several critical areas. Its application in these engines ensures that there are no leaks, which is vital for maintaining the engine’s performance and longevity.

QSZ90 Engines

In the QSZ90 engines, the 3336396 sealing washer is essential for preventing leaks in high-pressure systems. Its use in these engines helps to ensure that the engine operates efficiently and reliably.

Role of Part 3336396 Sealing Washer in Engine Systems

The 3336396 Sealing Washer is an essential component in maintaining the integrity and efficiency of various engine systems. It is strategically placed in several key areas to ensure optimal performance and prevent leaks.

Air Inlet and Exhaust Systems

In the air inlet sub-assembly, the Sealing Washer ensures a tight seal between the air inlet and the cylinder block, preventing air leaks that could affect engine performance. Similarly, in the exhaust assembly and exhaust manifold, it maintains a secure seal, ensuring that exhaust gases are efficiently directed away from the engine without any leakage.

Fuel System

Within the fuel pump and fuel assembly filter, the Sealing Washer plays a vital role in maintaining the pressure integrity of the fuel system. It ensures that fuel is delivered consistently to the engine without any loss due to leaks, which is essential for maintaining engine efficiency and performance.

Cooling System

In the engine coolant system, particularly in components like the oil cooler assembly and thermostat sub-assembly cover, the Sealing Washer is used to prevent coolant leaks. This is important for maintaining the engine’s operating temperature within safe limits, thereby protecting the engine from overheating and potential damage.

Drive and Accessory Systems

The Sealing Washer is also found in the front gear train accessory and drive components, where it ensures that these moving parts operate smoothly without any lubricant leakage. This is important for the longevity and reliability of the engine’s drive system.

Electronic and Monitoring Systems

In the electronic governor and engine monitoring system, the Sealing Washer is used to ensure that sensitive electronic components are protected from environmental factors such as moisture and dust. This helps in maintaining the accuracy and reliability of the engine’s electronic systems.

Miscellaneous Applications

Additionally, the Sealing Washer is utilized in various other components such as the cylinder block hardware kit, flywheel housing, and oil cooler seal kit. In each of these applications, its role is to provide a reliable seal, ensuring the efficient operation of the engine and its components.

Conclusion

The Cummins 3336396 Sealing Washer is a vital component in the maintenance and operation of commercial truck engines. Its role in preventing leaks and maintaining system pressure across various engine systems underscores its importance in ensuring the reliability, efficiency, and safety of these vehicles.

-

Van Gelder, K. T. (2018). Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning.

↩ -

Genta, G., & Morello, L. (2019). The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer.

↩ -

Bari, S. (2013). Diesel Engine Combustion, Emissions and Condition Monitoring. InTech.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.