This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

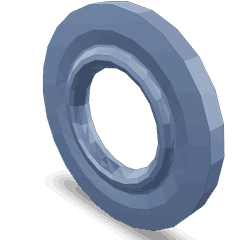

The Cummins 3336404 Sealing Washer is a component designed to ensure the integrity of fluid systems in heavy-duty trucks. Its role is to prevent leaks and maintain system efficiency, contributing to the overall performance and reliability of the vehicle.

Basic Concepts of Sealing Washers

Sealing washers are mechanical components used to create a seal between two surfaces, typically in fluid systems. They play a role in maintaining the integrity of these systems by preventing fluid leakage and ensuring that systems operate under the correct pressure. In the context of trucks, sealing washers are vital for the proper functioning of various fluid-based systems, including fuel, hydraulic, and cooling systems 1.

Purpose of the 3336404 Sealing Washer

The 3336404 Sealing Washer is specifically designed to fit into various truck systems where fluid sealing is required. It plays a role in ensuring that connections within these systems remain leak-free, thereby contributing to the efficient operation of the truck. Its application spans across different systems, highlighting its versatility and importance in maintaining vehicle performance.

Key Features

The 3336404 Sealing Washer is characterized by its material composition, which is selected for durability and resistance to the fluids it encounters. Its design specifications ensure a snug fit in the intended applications, and it may possess unique characteristics that enhance its sealing capabilities and longevity in demanding environments.

Benefits of Using the 3336404 Sealing Washer

Utilizing the 3336404 Sealing Washer offers several advantages. It contributes to improved sealing efficiency, which is crucial for maintaining system pressure and performance. Additionally, its durability and reliability make it a valuable component for ensuring long-term operation of truck fluid systems without frequent replacements.

Installation Process

Proper installation of the 3336404 Sealing Washer involves several steps to ensure it fits correctly and performs its intended function. This process may require specific tools and adherence to manufacturer guidelines to achieve the best results. Correct installation is key to ensuring the washer effectively seals the connection and withstands the operational conditions of the truck.

Common Issues and Troubleshooting

Sealing washers, including the 3336404, may encounter issues such as leaks or wear over time. Identifying these problems early and applying appropriate troubleshooting methods can help maintain the integrity of the fluid systems. Regular inspections and understanding the signs of wear can aid in addressing these issues promptly.

Maintenance Tips

Regular maintenance of the 3336404 Sealing Washer is important for its longevity and performance. This includes periodic inspections for signs of wear or damage, cleaning according to manufacturer recommendations, and replacing the washer as needed to prevent system failures.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the automotive and heavy-duty truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and technological advancements contribute to its leadership in the market.

Cummins Sealing Washer 3336404 Compatibility with Engine Models

The Cummins Sealing Washer part number 3336404 is designed to fit seamlessly with a variety of Cummins engine models. This part is crucial for ensuring proper sealing and preventing leaks in the engine system. Here is a detailed look at its compatibility with specific engine models:

ISBE CM800 Series

The ISBE CM800 engine series benefits from the use of the 3336404 sealing washer. This part is integral in maintaining the integrity of the engine’s sealing system, ensuring that the engine operates efficiently and reliably.

QSV Series

The 3336404 sealing washer is compatible with the following QSV models:

- QSV81G

- QSV91G

- QSW/QSV82

These engines rely on the sealing washer to maintain optimal performance and prevent any potential leakage issues. The washer’s design ensures a tight seal, which is essential for the longevity and efficiency of these engines.

QSW Series

The 3336404 sealing washer is also suitable for the following QSW models:

- QSW27

- QSW36

- QSW73

These engines, known for their robust performance, require the precision and reliability of the 3336404 sealing washer to maintain their sealing integrity. The washer’s fit and function are critical in ensuring that these engines perform at their best.

QSZ90

The QSZ90 engine also utilizes the 3336404 sealing washer. This part is essential in maintaining the sealing system of the QSZ90, ensuring that the engine operates with minimal leaks and maximum efficiency.

By ensuring that the 3336404 sealing washer is correctly installed, engine operators can maintain the performance and reliability of their engines, preventing potential issues that could arise from inadequate sealing.

Role of Part 3336404 Sealing Washer in Engine Systems

The part 3336404 Sealing Washer is integral to the efficient operation of various engine systems by ensuring the integrity of fluid pathways and preventing leaks.

In the Air Intake Manifold, the sealing washer is used at connection points to maintain airtight seals, which is essential for optimal air-fuel mixture and engine performance.

At the Assembly Flange of the Cooler and Engine Oil systems, the sealing washer ensures that there are no leaks between the flange and the cooler or oil passages, maintaining system pressure and efficiency.

Within the Front Gear Train Accessory and the Engine Oil Assembly Cooler, the sealing washer plays a role in securing connections, thereby preventing oil leaks which could lead to decreased lubrication and increased wear on moving parts.

In the Filter Fuel Assembly and Fuel Assembly Filter, the sealing washer is employed to create a secure seal at connection points, ensuring that fuel is delivered without contamination or loss.

For the Fuel Assembly L8 Plumbing, Fuel Assembly Plumbing, and Fuel Assembly Prefilter, the sealing washer is critical in maintaining the integrity of the fuel lines, preventing any fuel leakage which could be hazardous.

In the Fuel Assembly Pump and Fuel Block Connection, the sealing washer ensures that the pump operates efficiently by maintaining a sealed environment, which is necessary for consistent fuel pressure.

The Fuel Sub-Assembly Plumbing relies on the sealing washer to keep the fuel lines sealed, which is vital for the safe and efficient transfer of fuel throughout the system.

In the Housing of the Oilcooler Subassy and the Lubricating Oil Assembly Pump, the sealing washer is used to prevent oil leaks, ensuring that the lubrication system remains pressurized and effective.

The Manifold Air Intake uses the sealing washer to ensure that the air entering the engine is clean and metered correctly, which is important for combustion efficiency.

In the Oil Assembly Pan and Pan Oil, the sealing washer is employed to keep the oil contained within the pan, preventing leaks that could lead to oil loss and contamination.

The Plumbing Fuel system incorporates the sealing washer to maintain the integrity of fuel lines, ensuring safe and efficient fuel delivery.

In the Power Take Off Assembly Gear and Power Take-Off Assembly Housing, the sealing washer is used to secure connections, preventing leaks that could affect the operation of auxiliary equipment driven by the engine.

The Pump Fuel Transfer and Pump Lubricating Oil systems utilize the sealing washer to ensure that fluids are transferred without leakage, maintaining system pressure and efficiency.

Finally, in the Sea Water and Power Take-Off Assembly Housing and Sea Water Pump Housing, the sealing washer is essential for preventing sea water ingress into the engine system, which could lead to corrosion and damage.

Conclusion

The Cummins 3336404 Sealing Washer plays a vital role in maintaining the integrity of fluid systems in heavy-duty trucks. Its proper installation, maintenance, and compatibility with various Cummins engine models ensure efficient operation and reliability of the vehicle. By understanding the importance of this part and following recommended practices, operators can enhance the performance and longevity of their engines.

-

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.