This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

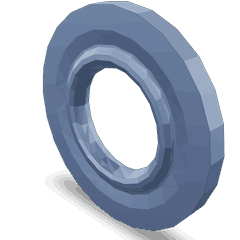

The Cummins 3336405 Sealing Washer is a component designed for use in commercial trucks. It serves a specific function within the truck’s mechanical systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and role is fundamental for maintaining and optimizing truck performance.

Basic Concepts of Sealing Washers

Sealing washers are mechanical components used to create a seal between two surfaces, preventing the leakage of fluids or gases. They function by filling the gap between mating surfaces, ensuring that the system remains closed and operates efficiently. In mechanical systems, sealing washers are vital for maintaining pressure, preventing contamination, and ensuring the longevity of the components they protect 1.

Purpose of the 3336405 Sealing Washer

The Cummins 3336405 Sealing Washer plays a role in the operation of a truck by providing a reliable seal in various engine or system applications. Its function is to prevent leaks, maintain system pressure, and protect sensitive components from damage due to fluid or gas leakage. This washer is integral to ensuring that the truck’s engine and other systems operate within specified parameters, contributing to overall vehicle performance and durability.

Key Features

The Cummins 3336405 Sealing Washer is characterized by its material composition, which is selected for durability and resistance to the operating conditions it will encounter. Its design specifications include precise dimensions to ensure a proper fit and effective sealing. Unique characteristics may include enhanced flexibility for better adaptation to dynamic environments or resistance to specific chemicals encountered in truck applications.

Benefits of Using the 3336405 Sealing Washer

Utilizing the Cummins 3336405 Sealing Washer offers several advantages. It provides improved sealing efficiency, which is crucial for maintaining system integrity and performance. The washer’s durability ensures long-term reliability, reducing the need for frequent replacements. Its design contributes to the overall reliability of the truck’s mechanical systems, supporting consistent operation in demanding applications.

Installation Guidelines

Proper installation of the Cummins 3336405 Sealing Washer is crucial for ensuring optimal performance. The process involves cleaning the mating surfaces to remove any debris or old sealant. The washer should be placed correctly according to the manufacturer’s specifications, ensuring it is not twisted or misaligned. Tools required may include a torque wrench for tightening fasteners to the specified torque, ensuring the washer is held in place without being overtightened, which could damage the washer or the surfaces it seals.

Maintenance Tips

Maintaining the Cummins 3336405 Sealing Washer involves regular inspection for signs of wear or damage. Inspection intervals should be aligned with the truck’s maintenance schedule, allowing for early detection of potential issues. Cleaning the washer and its mating surfaces as part of routine maintenance can prevent contamination that may lead to failure. Signs of wear, such as cracks or deformation, indicate the need for replacement to maintain system integrity.

Troubleshooting Common Issues

Common problems associated with sealing washers include leaks and failure due to wear or improper installation. Troubleshooting steps involve inspecting the washer and its installation for any visible signs of damage or misalignment. Ensuring that the mating surfaces are clean and free of debris can also help resolve issues. In cases where the washer appears worn or damaged, replacement with a new washer is recommended to restore system functionality.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, Cummins is committed to manufacturing high-quality components for commercial vehicles. The company’s focus on innovation, quality, and customer satisfaction has established it as a trusted name in the production of engine components and systems 2.

Cummins Sealing Washer Part 3336405 Compatibility with Engine Models

The Cummins sealing washer part number 3336405 is designed to fit seamlessly within a variety of engine models, ensuring optimal performance and reliability. This part is crucial for maintaining the integrity of the engine’s sealing system, preventing leaks, and ensuring efficient operation.

Engine Compatibility

QSV81G and QSV91G Engines

The sealing washer part 3336405 is compatible with the QSV81G and QSV91G engines. These engines are known for their robust design and high performance, often used in heavy-duty applications. The washer ensures that the sealing system remains intact, preventing any potential oil or coolant leaks that could compromise engine efficiency.

QSW/QSV82 Engines

For the QSW/QSV82 engines, the sealing washer part 3336405 is an essential component. These engines are typically used in a variety of industrial applications, and the washer helps maintain the sealing integrity of the engine, ensuring that the engine operates smoothly and efficiently.

QSW27 and QSW36 Engines

The QSW27 and QSW36 engines also benefit from the use of the sealing washer part 3336405. These engines are commonly used in agricultural and construction equipment, where durability and reliability are paramount. The washer plays a critical role in maintaining the sealing system, preventing leaks and ensuring the engine’s longevity.

QSW73 Engines

The QSW73 engine is another model that is compatible with the sealing washer part 3336405. This engine is often used in heavy-duty applications, and the washer ensures that the sealing system remains effective, preventing any potential issues that could arise from leaks.

QSZ90 Engines

Finally, the QSZ90 engine is also compatible with the sealing washer part 3336405. This engine is known for its high performance and reliability, and the washer is a crucial component in maintaining the sealing system’s integrity, ensuring the engine operates at peak efficiency.

Role of Part 3336405 Sealing Washer in Engine Systems

Part 3336405, the Sealing Washer, is integral to maintaining the integrity and efficiency of various engine systems. Its application spans across multiple components, ensuring that fluids and gases remain contained within their designated pathways, thereby preventing leaks and maintaining system pressure.

Coolant System

In the coolant system, the Sealing Washer is employed in the coolant heater starting aid and the expansion assembly tank. It ensures that the coolant remains within the system, preventing any loss of coolant which could lead to engine overheating. Additionally, it is used in the heat exchanger to maintain the efficiency of heat transfer between the coolant and the surrounding air.

Lubricating Oil System

Within the lubricating oil system, the Sealing Washer is crucial in components such as the lubricating oil assembly plumbing, lubricating oil assembly pump, and the oil assembly pan. It helps in maintaining the pressure within the oil lines, ensuring that the oil reaches all moving parts effectively, thereby reducing friction and wear.

Fuel System

In the fuel system, the Sealing Washer is utilized in the fuel assembly filter and the fuel pump assembly cover. It ensures that fuel lines remain sealed, preventing any fuel leaks which could be hazardous. Additionally, it is used in the flywheel housing plumbing to maintain the integrity of the fuel delivery system.

Engine Control and Monitoring Systems

The Sealing Washer also plays a role in the engine control system and the engine monitoring system. In these applications, it ensures that any fluids or gases used in the control mechanisms are properly contained, allowing for accurate and reliable engine performance monitoring and control.

Accessory Drives and Gear Trains

In the front gear train accessory drive, the Sealing Washer is used to ensure that lubricants remain within the gear housing, promoting smooth operation and longevity of the gear components.

Enclosures and Covers

The Sealing Washer is also found in various enclosures and covers such as the enclosure side B cover and the cover plate. Here, it ensures that any fluids or gases within the engine compartment do not escape, maintaining the overall integrity of the engine environment.

Additional Applications

Other notable applications include the oil assembly tube, oil pre-lube pump, and the gear assembly housing. In each of these components, the Sealing Washer ensures that the system functions as intended, without any unwanted leaks or pressure drops.

Overall, the Sealing Washer (Part 3336405) is a versatile component that enhances the reliability and efficiency of various engine systems by ensuring proper sealing and containment of fluids and gases.

Conclusion

The Cummins 3336405 Sealing Washer is a critical component in the maintenance and operation of commercial trucks. Its role in preventing leaks, maintaining system pressure, and protecting sensitive components is essential for the overall performance and durability of the vehicle. Proper installation, regular maintenance, and timely replacement of this part are key to ensuring the efficient and reliable operation of the truck’s engine and mechanical systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.