This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

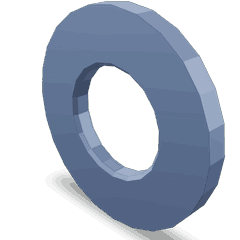

The 3336589 Flat Washer, manufactured by Cummins, is a component designed for use in commercial truck applications. Cummins, a well-established name in the commercial truck industry, produces a range of parts and components that are integral to the operation and maintenance of heavy-duty vehicles. This Cummins part plays a role in ensuring the efficient and reliable performance of commercial trucks.

Basic Concepts of Flat Washers

Flat washers are simple yet vital components in mechanical assemblies. Their primary function is to distribute the load of a threaded fastener, such as a bolt or screw, over a larger area. This distribution helps prevent damage to the surface material by reducing the pressure exerted by the fastener. Additionally, flat washers can provide a degree of insulation between the fastener and the surface, which can be particularly useful in applications where electrical conductivity needs to be minimized 1.

Purpose of the 3336589 Flat Washer in Truck Operations

In the context of commercial truck operations, the 3336589 Flat Washer serves multiple functions. It is utilized in various truck components where load distribution and surface protection are necessary. For instance, it may be employed in the fastening of body panels, in the assembly of engine components, or in the securing of chassis parts. By ensuring even load distribution, the washer helps maintain the integrity of the fastened components and contributes to the overall durability and safety of the truck 2.

Key Features of the 3336589 Flat Washer

The 3336589 Flat Washer is engineered with specific design and material characteristics that make it well-suited for heavy-duty truck applications. It is constructed from materials that offer high load-bearing capacity, ensuring it can withstand the stresses encountered in commercial truck operations. Additionally, the washer is designed to resist wear and corrosion, which are common challenges in the demanding environments trucks often operate in. These features contribute to the washer’s reliability and longevity in truck applications 3.

Benefits of Using the 3336589 Flat Washer

Utilizing the 3336589 Flat Washer in truck applications offers several advantages. Its robust design and material properties contribute to enhanced durability, allowing it to perform reliably under the strenuous conditions typical of commercial truck use. The washer’s ability to distribute load effectively helps protect the surfaces it is applied to, reducing the risk of damage and extending the life of the components it is used with. Furthermore, by ensuring secure and stable fastening, the 3336589 Flat Washer contributes to the prolonged operational life of truck components 4.

Installation and Usage Guidelines

Correct installation of the 3336589 Flat Washer is key to ensuring its optimal performance and the safety of truck operations. It should be placed under the head of a bolt or screw, or within a nut, depending on the specific application. Care should be taken to ensure that the washer is properly aligned and seated to achieve the intended load distribution and surface protection. Following manufacturer guidelines for torque settings when tightening fasteners is also important to avoid over-tightening, which can lead to washer deformation or failure.

Troubleshooting and Maintenance

Regular inspection of flat washers in truck applications can help identify common issues such as wear, corrosion, or deformation. Maintenance practices, such as cleaning and lubricating washers as part of routine truck servicing, can extend their lifespan. If a washer shows signs of significant wear or damage, it should be replaced to maintain the integrity and safety of the fastened components. Keeping spare washers on hand can facilitate quick replacements when needed.

Cummins: A Brief Overview

Cummins is a renowned manufacturer in the commercial truck industry, with a history of producing high-quality parts and components. The company’s product range includes engines, powertrains, and various aftermarket parts, all designed to meet the demanding requirements of heavy-duty truck applications. Cummins’ reputation for reliability, performance, and innovation has made it a trusted name among truck operators and maintenance professionals.

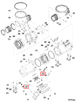

Cummins Flat Washer Part 3336589 Compatibility with Various Engines

The Cummins Flat Washer part number 3336589 is a versatile component that fits into several engine models. This part is designed to provide a secure and stable connection in various engine configurations, ensuring optimal performance and longevity.

QSV81G, QSV91G, and QSW/QSV82 Engines

The Flat Washer part 3336589 is compatible with the QSV81G, QSV91G, and QSW/QSV82 engines. These engines often require precise fitting components to maintain their operational integrity. The washer’s design allows it to fit snugly in these models, providing the necessary support and stability.

QSW27, QSW36, and QSW73 Engines

Similarly, the QSW27, QSW36, and QSW73 engines benefit from the use of the Cummins Flat Washer part 3336589. These engines, known for their robust performance, require high-quality components to ensure smooth operation. The washer’s compatibility with these models ensures that they can maintain their efficiency and reliability.

QSZ90 Engine

The QSZ90 engine also utilizes the Cummins Flat Washer part 3336589. This engine, like the others, relies on precise and durable components to function optimally. The washer’s design fits seamlessly into the QSZ90, providing the necessary support and stability.

QSV91-G4 CM558/CM700 V102 Engine

Lastly, the QSV91-G4 CM558/CM700 V102 engine is another model that benefits from the Cummins Flat Washer part 3336589. This engine, with its advanced features, requires components that can handle its specific demands. The washer’s compatibility with this engine ensures that it can maintain its high performance and reliability.

By ensuring that the Cummins Flat Washer part 3336589 fits into these various engine models, it provides a reliable and consistent solution for maintaining engine integrity across different applications.

Role of Part 3336589 Flat Washer in Engine Systems

The part 3336589 Flat Washer is a component in various engine systems, providing necessary spacing, distribution of load, and prevention of damage to adjacent parts. Here’s how it integrates with several key engine components:

Air Assembly Cleaner

In the air assembly cleaner, the flat washer ensures proper spacing between the cleaner housing and mounting brackets. This spacing is vital for maintaining the structural integrity and alignment of the air cleaner, which is responsible for filtering incoming air before it enters the engine.

Assembly Bellows

Within the assembly bellows, the flat washer helps to maintain the necessary gap between the bellows and its mounting points. This ensures that the bellows can expand and contract without undue stress, preserving its flexibility and sealing capabilities.

Assembly Preheater

In the assembly preheater, the flat washer is used to separate the preheater unit from its mounting surface. This separation allows for thermal expansion and contraction, preventing warping and ensuring consistent preheater performance.

Camshaft Assembly Gear

The flat washer in the camshaft assembly gear setup provides essential spacing between the gear and its mounting surface. This ensures that the gear operates smoothly without undue friction or binding, which could otherwise lead to premature wear.

Cover

For engine covers, the flat washer is employed to create a uniform gap between the cover and the engine block. This gap is important for proper sealing and to prevent any potential leaks that could compromise engine performance.

Hotbox Assembly

In the hotbox assembly, the flat washer helps to distribute the load evenly across the mounting points. This even distribution is crucial for maintaining the structural integrity of the hotbox, which houses high-temperature components.

Exhaust Assembly Manifold and Exhaust Manifold

Within the exhaust assembly manifold and exhaust manifold, the flat washer ensures proper spacing between the manifold and its mounting points. This spacing is important for thermal management and to prevent cracking due to uneven heating.

Filter and Fuel Assembly Components

In fuel-related components such as the fuel assembly filter, fuel assembly L8 plumbing, fuel assembly plumbing, fuel assembly pump, fuel block connection, fuel priming assembly pump, and fuel sub-assembly plumbing, the flat washer ensures that connections are secure yet allow for necessary movement and expansion. This is particularly important in fuel systems where precise fitting and sealing are required to prevent leaks and ensure efficient fuel delivery.

Heat Assembly Shield

The flat washer in the heat assembly shield helps to maintain a consistent gap between the shield and its mounting points. This gap is essential for effective heat dissipation and to prevent the shield from warping under thermal stress.

Multiduct Connection

In multiduct connections, the flat washer ensures that ducts are properly spaced and aligned. This alignment is crucial for maintaining airflow efficiency and preventing turbulence that could affect engine performance.

Oil Pan

For the oil pan, the flat washer provides necessary spacing between the pan and its mounting surface. This ensures that the pan remains level and securely attached, which is important for maintaining oil levels and preventing leaks.

Priming Pump Fuel Assembly and Single Fuel Filter Assembly

In these assemblies, the flat washer ensures that connections are tight yet allow for necessary movement. This is vital for maintaining the integrity of fuel lines and filters, ensuring consistent fuel pressure and flow.

Support and Accessory Sub-Assembly

In support and accessory sub-assemblies, the flat washer helps to distribute loads evenly across mounting points. This even distribution is important for the longevity and reliability of these components.

Turbocharger L6 and L8 Assemblies

In turbocharger assemblies, the flat washer ensures proper spacing between the turbocharger and its mounting points. This is essential for maintaining the turbocharger’s alignment and operational efficiency, which directly impacts engine performance.

Valve Assembly Safety

Finally, in the valve assembly safety, the flat washer ensures that valves are properly spaced from their housing. This spacing is important for the reliable operation of safety valves, which are critical for maintaining safe operating pressures within the engine.

Conclusion

The 3336589 Flat Washer by Cummins is a critical component in the maintenance and operation of commercial trucks. Its design and material properties ensure durability and reliability in heavy-duty applications. Proper installation and maintenance of this part are essential for the optimal performance and safety of truck operations. By understanding the role and benefits of the 3336589 Flat Washer, truck operators and maintenance professionals can ensure the longevity and efficiency of their vehicles.

-

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩ -

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

Eret, A. (2024). Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature.

↩ -

Happian-Smith, J. (2002). An Introduction to Modern Vehicle Design. Butterworth-Heinemann.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.