This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

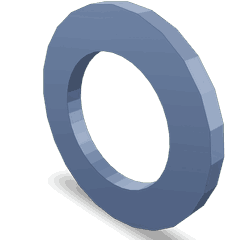

The Cummins 3336591 Plain Washer is a component designed for use in commercial trucks. It serves a specific function within the truck’s mechanical systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and role is fundamental for maintaining and optimizing truck performance.

Basic Concepts of Plain Washers

Plain washers are simple yet vital components in mechanical systems. They are typically flat, annular metal rings that distribute load, reduce wear, and provide spacing between parts. In operation, plain washers help to evenly distribute the force applied by a fastener, such as a bolt or screw, across a larger surface area. This reduces the risk of damage to the surfaces in contact and enhances the stability of the assembly 1.

Purpose of the Cummins 3336591 Plain Washer

The Cummins 3336591 Plain Washer is specifically engineered to play a role in the fastening systems of commercial trucks. It is part of an assembly where it helps to distribute the load from bolts or screws, ensuring that the force is spread evenly across the mating surfaces. This contributes to the longevity of the components and the overall stability of the truck’s structure 2.

Key Features

The Cummins 3336591 Plain Washer is characterized by its material composition, typically made from high-quality steel to ensure durability and resistance to wear. Its dimensions are precisely engineered to fit specific applications within commercial trucks. Unique characteristics may include a specific thickness or outer diameter that differentiates it from other plain washers, ensuring it meets the exact requirements of its intended use 3.

Benefits

The Cummins 3336591 Plain Washer offers several benefits. It improves load distribution, which helps to prevent damage to mating surfaces caused by concentrated force. Additionally, it reduces wear on these surfaces, contributing to the longevity of the components. The washer also enhances the overall stability of the assembly it is part of, ensuring that the truck operates smoothly and reliably 4.

Installation Considerations

Proper installation of the Cummins 3336591 Plain Washer is crucial for its effective function. Guidelines include adhering to torque specifications to ensure the fastener is tightened to the correct level without over-tightening, which could lead to damage. Orientation is also important; the washer should be placed correctly in the assembly to fulfill its load-distributing role. Precautions during installation may include ensuring the surfaces are clean and free from debris to prevent interference with the washer’s function.

Troubleshooting and Maintenance

Common issues with plain washers, such as wear, corrosion, or improper fit, can be addressed through regular inspection and maintenance. Signs of wear or corrosion should be addressed promptly to prevent failure. Ensuring the washer is the correct fit for its application is also important. Regular maintenance practices, such as cleaning and inspecting the washer and its mating surfaces, can help ensure longevity and optimal performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a key player in the commercial truck industry, offering a wide range of products designed to enhance the performance, efficiency, and reliability of commercial vehicles.

Cummins Engine Part 3336591: Plain Washer Application

The Cummins part number 3336591, a Plain Washer, is a critical component in the maintenance and operation of several Cummins engine models. This part is designed to provide a smooth and secure interface between various engine parts, ensuring optimal performance and longevity.

Application in Cummins Engines

QSK60 CM850 MCRS, QSV81G, QSV91G, QSW/QSV82, QSW27, QSW36, QSW73, QSZ90

The Plain Washer 3336591 is integral to the assembly and function of these engines. It is used in multiple areas within the engine to maintain the integrity of the connections and prevent leaks. The washer’s role is to distribute the load evenly, reduce friction, and maintain the correct clearance between mating surfaces.

Specific Uses in Engine Models

- QSK60 CM850 MCRS: In this engine, the Plain Washer 3336591 is often used in the fuel injection system, ensuring that the injectors are properly sealed and aligned.

- QSV81G and QSV91G: These engines utilize the washer in various components, including the turbocharger system, to maintain precise tolerances and prevent oil or air leaks.

- QSW/QSV82: Here, the washer is crucial in the engine’s cooling system, ensuring that the water pump and related components are securely fastened.

- QSW27, QSW36, QSW73: These engines incorporate the Plain Washer 3336591 in the exhaust system, helping to maintain a tight seal and prevent exhaust leaks.

- QSZ90: In this model, the washer is used in the engine’s lubrication system, ensuring that oil passages remain sealed and oil flow is unimpeded.

By providing a reliable sealing and fastening solution, the Plain Washer 3336591 contributes to the overall efficiency and reliability of these Cummins engines.

Role of Part 3336591 Plain Washer in Various Engine Components

In the intricate world of engine systems, the part 3336591 Plain Washer serves as a fundamental component that ensures the smooth operation and longevity of various assemblies. Here’s how it integrates with several key components:

-

Air Assembly Cleaner and Air Assembly Tank: The Plain Washer is utilized to maintain a secure seal between the components of the air cleaner and tank, preventing air leaks that could affect engine performance.

-

Air Outlet Assembly Pipe: It ensures a tight seal at connection points, which is vital for maintaining the correct air-fuel mixture and preventing any unwanted air from entering the system.

-

Air Shut Down Assembly Device: This device relies on the Plain Washer to create a reliable seal, ensuring that the air supply can be effectively cut off when needed without any leakage.

-

Assembly Gas Circuit and Circuit Assembly Gas: Within the gas circuit assemblies, the Plain Washer helps to seal connections, ensuring that the gas flow is consistent and uncontaminated.

-

Assembly Ignition: The ignition system components are sealed using the Plain Washer, which is essential for maintaining the integrity of the electrical connections and preventing any short circuits.

-

Assembly Preheater: In preheater assemblies, the Plain Washer is used to ensure that heat is efficiently transferred without any loss, contributing to the engine’s warm-up process.

-

Engine Control Assembly: This complex assembly requires precise sealing at various points, where the Plain Washer plays a role in maintaining the accuracy of sensor readings and control signals.

-

Engine Oil Cooler: The Plain Washer is employed to seal the connections in the oil cooler, ensuring that the oil circulates without leaks, which is crucial for engine lubrication and cooling.

-

Exhaust Manifold: In the exhaust system, the Plain Washer helps to seal the manifold to the engine block, preventing exhaust gases from escaping and ensuring efficient exhaust flow.

-

Filter Fuel Assembly: The fuel filter assembly uses the Plain Washer to seal the connections, which is important for maintaining clean fuel delivery to the engine.

-

Fuel Pump Assembly Cover and Fuel Pump Sub-assembly Cover: These covers are sealed with the Plain Washer to ensure that the fuel system remains pressurized and leak-free.

-

Gear Assembly Housing: The Plain Washer is used in the gear assembly to seal the housing, which is essential for keeping contaminants out and lubricants in.

-

Heat Assembly L6 Exchanger: This heat exchanger relies on the Plain Washer to seal the connections, ensuring efficient heat transfer and preventing any fluid leaks.

-

Oil Pan: The Plain Washer is used to seal the oil pan to the engine block, which is vital for containing the engine oil and preventing leaks.

-

Orifice Assembly Plug: In orifice assemblies, the Plain Washer ensures that the plug is securely in place, which is important for maintaining the correct flow rates within the system.

-

Plumbing: Throughout the engine’s plumbing system, the Plain Washer is used to seal connections, which is essential for the integrity of the fluid pathways.

-

Turbocharger: The turbocharger uses the Plain Washer to seal various connections, ensuring that the compressed air is delivered to the engine without any loss of pressure.

-

Pump Drive Assembly Housing: This housing is sealed with the Plain Washer to ensure that the pump drive operates efficiently without any fluid leaks.

-

Pump Side B V18 Injector Cover: The injector cover is sealed with the Plain Washer to maintain the integrity of the fuel injection system.

-

Engine Monitoring System: Within the engine monitoring system, the Plain Washer is used to seal electronic components, ensuring that they operate in a controlled environment without exposure to contaminants.

-

Water Outlet Connection: The Plain Washer seals the water outlet connection, which is important for maintaining the coolant flow and preventing leaks in the cooling system.

Conclusion

The Cummins 3336591 Plain Washer is a critical component in the maintenance and operation of commercial trucks and various Cummins engine models. Its role in load distribution, reducing wear, and ensuring the stability of assemblies contributes significantly to the efficiency and reliability of these vehicles. Proper installation, regular maintenance, and understanding its application across different engine components are essential for maximizing the performance and longevity of the truck and its engine systems.

-

Isermann, R. (2017). Combustion Engine Diagnosis. Springer Vieweg.

↩ -

Brown Jr, A. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

↩ -

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.