This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3504233 Lock Washer is a component manufactured by Cummins, a well-established name in the commercial truck industry. This Cummins part is designed for use in fastening systems within commercial trucks, where it plays a significant role in maintaining the integrity of bolted connections. Lock washers, in general, are used to prevent the loosening of fasteners, which can be particularly problematic in the dynamic and often harsh environments encountered by commercial trucks 1.

Basic Concepts of Lock Washers

Lock washers are specialized washers used in mechanical assemblies to prevent the loosening of fasteners. They achieve this by introducing tension or deformation to the fastener, which creates additional friction and resistance to movement. This is particularly important in applications where vibrations or dynamic loads are present, as these can cause standard washers to fail in maintaining a secure connection 2.

Purpose of the 3504233 Lock Washer in Truck Operations

The 3504233 Lock Washer is specifically designed to enhance the fastening systems in commercial trucks. It is utilized in environments where vibrations and dynamic loads are common, such as in the engine compartment, undercarriage, and various other truck components. By preventing fastener loosening, this lock washer contributes to the overall safety and reliability of the truck, ensuring that critical components remain securely fastened during operation 3.

Key Features

This part is characterized by its robust material composition and design elements that are tailored for durability and performance. It is typically made from high-strength steel, which provides the necessary resilience to withstand the stresses encountered in commercial truck applications. The design of the washer includes features that enhance its locking mechanism, ensuring a secure fit with the fastener 4.

Benefits

Utilizing the 3504233 Lock Washer offers several advantages. It provides improved fastening security by preventing the loosening of bolts and nuts, which is vital in maintaining the structural integrity of truck components. Additionally, its design contributes to longevity under stress, making it suitable for the demanding conditions faced by commercial trucks. The washer also exhibits resistance to vibration and environmental factors, further enhancing its reliability in truck operations 1.

Installation Guidelines

Proper installation of the 3504233 Lock Washer is key to ensuring optimal performance and longevity. It should be installed beneath the nut or bolt head, with the locking tab oriented correctly to engage with the fastener. It is important to pair the lock washer with appropriate fasteners and use the correct tools to achieve the recommended torque specifications. This ensures that the washer functions as intended and provides the necessary security for the fastening system 2.

Troubleshooting and Maintenance

Common issues with lock washers include deformation or failure of the locking mechanism, which can lead to fastener loosening. Regular inspection of lock washers for signs of wear or damage is recommended to identify potential issues early. Maintenance routines should include checking the condition of the washers and replacing them as necessary to ensure continued reliability of the fastening system 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s extensive product range includes components like the 3504233 Lock Washer, which are trusted by professionals for their performance and durability in demanding applications 4.

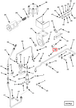

Role of Part 3504233 Lock Washer in Engine Systems

In the context of engine systems, the 3504233 Lock Washer is instrumental in ensuring the secure attachment of various components. When integrated with an Actuator, the Lock Washer prevents loosening due to vibrations, thereby maintaining the actuator’s precise control over engine functions.

For the Control System, it ensures that electrical connections and sensor mounts remain firmly in place, which is essential for accurate data transmission and system responsiveness.

In the Engine Brake mechanism, the Lock Washer plays a part in securing the components that modulate the brake’s engagement, contributing to consistent performance and safety.

With the Exhaust Brake Control, it helps in maintaining the integrity of the connections that manage the flow of exhaust gases, which is vital for effective braking and engine deceleration.

In a Service Kit, the inclusion of the Lock Washer is a testament to its importance in preserving the tightness of fasteners during maintenance procedures, ensuring that all replaced or repaired parts function as intended.

For the Turbocharger, the Lock Washer is used to secure the mounting brackets and other critical attachments, which is important for the turbocharger’s operation under high-stress conditions.

Lastly, in the Turbocharger Brake Actuator, the Lock Washer ensures that the actuator components are held in place, allowing for reliable modulation of the turbocharger’s braking function, which is essential for engine protection and performance.

Conclusion

The 3504233 Lock Washer is a critical component in the maintenance and operation of commercial trucks, offering enhanced fastening security and reliability in demanding environments. Its robust design and material composition make it well-suited for the stresses encountered in truck applications, contributing to the overall safety and performance of the vehicle. Regular maintenance and proper installation are essential to ensure the continued effectiveness of this Cummins part in securing critical components within the truck’s engine systems.

-

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ ↩ -

Hilgers, M. (2023). Chassis and Axles. Springer Vieweg.

↩ ↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ ↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.