This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

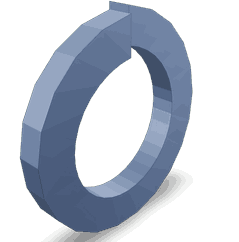

The Cummins 3907481 Lock Washer is a specialized component designed for use in heavy-duty truck applications. Its purpose is to enhance the security of fastening systems, ensuring that bolts and nuts remain tightly fastened under dynamic conditions. This part plays a role in maintaining the integrity and reliability of truck components, contributing to overall vehicle performance and safety 1.

Basic Concepts of Lock Washers

Lock washers are designed to prevent fastened joints from loosening due to vibration or rotation. Unlike standard washers, which primarily distribute load and prevent damage to the surface, lock washers incorporate features that create mechanical resistance against loosening. This is achieved through various designs, such as split washers, toothed washers, or washers with serrated edges, which dig into the mating surfaces when tightened, providing additional friction and resistance to movement 2.

Purpose of the Cummins 3907481 Lock Washer

In heavy-duty truck applications, the Cummins 3907481 Lock Washer serves to secure critical fastenings that are subject to significant stress and vibration. By preventing bolts and nuts from loosening, it helps maintain the structural integrity of truck components, ensuring that connections remain secure throughout the vehicle’s operation. This is particularly important in applications where failure of a fastening could lead to safety hazards or costly repairs 3.

Key Features

The Cummins 3907481 Lock Washer is characterized by its robust design and material composition, which are tailored to withstand the demanding conditions of heavy-duty truck environments. It features a split design with serrated edges that provide enhanced locking capability by gripping the mating surfaces when tightened. The material used in its construction is selected for its durability and resistance to corrosion, ensuring longevity in harsh operating environments.

Benefits

Using the Cummins 3907481 Lock Washer offers several advantages in truck maintenance. It provides improved fastening security, reducing the risk of bolts and nuts loosening under vibration. This enhances the reliability of truck components and contributes to safer operation. Additionally, its design and material composition ensure longevity, even in challenging conditions, making it a cost-effective solution for maintaining fastening integrity.

Installation Considerations

Proper installation of the Cummins 3907481 Lock Washer is crucial for ensuring its effectiveness. It should be installed according to manufacturer specifications, with attention to torque settings to achieve the desired locking effect without over-tightening. Compatibility with other fasteners should be verified to ensure optimal performance. Following best practices for installation, such as using the correct tools and techniques, will help maximize the washer’s effectiveness and longevity.

Troubleshooting and Maintenance

Common issues with lock washers include deformation or failure due to over-tightening or exposure to harsh conditions. Regular inspection for signs of wear or damage is recommended to identify potential problems early. Maintenance tips include ensuring proper installation and torque settings, as well as replacing washers as needed to maintain fastening security. Following these guidelines can help prolong the life of the Cummins 3907481 Lock Washer and ensure continued reliability.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a strong reputation in the automotive and heavy-duty truck industry, Cummins is known for its commitment to quality and innovation. The company’s extensive product range and focus on customer satisfaction underscore its position as a trusted provider of components like the 3907481 Lock Washer, which are designed to meet the rigorous demands of heavy-duty applications.

Role of Part 3907481 Lock Washer in Engine Systems

In the context of engine systems, the 3907481 Lock Washer is instrumental in ensuring the secure and reliable operation of various components. When integrated with a Fuel Solenoid Kit, the Lock Washer plays a significant role in maintaining the integrity of the fuel delivery system.

Fuel Solenoid Kit Integration

Within the Fuel Solenoid Kit, the 3907481 Lock Washer is typically employed to prevent the loosening of fasteners that secure the solenoid to the fuel system. This is particularly important as the solenoid controls the flow of fuel to the engine, and any loosening could result in inconsistent fuel delivery, potentially leading to engine performance issues.

The Lock Washer achieves this by providing additional friction between the fastener and the surface it is attached to. This friction helps to counteract the vibrational forces that are common in engine environments, thereby ensuring that the solenoid remains firmly in place.

Moreover, the Lock Washer contributes to the overall stability of the fuel solenoid, which is essential for precise fuel metering. Accurate fuel metering is vital for optimal engine operation, affecting everything from fuel efficiency to emissions control.

Conclusion

In summary, the Cummins 3907481 Lock Washer, when used in conjunction with a Fuel Solenoid Kit, enhances the reliability and performance of the fuel delivery system by ensuring that all connections remain secure under operational conditions. Its robust design, material composition, and locking mechanism make it a critical component in maintaining the integrity of heavy-duty truck applications.

-

Owen C Duffy and Gus Wright, Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems (Jones Bartlett Learning, 2016).

↩ -

Rolf Isermann, Combustion Engine Diagnosis (Springer Vieweg, 2017).

↩ -

Robert Huzij, Angelo Spano, Sean Bennett, Modern Diesel Technology Heavy Equipment Systems (Delmar Cengage Learning, 2014).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.