Introduction

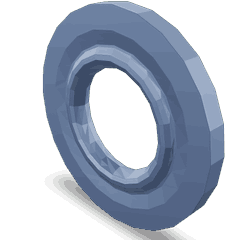

The Cummins 3921376 Sealing Washer is a component designed to ensure the integrity of fluid systems in commercial trucks. Its role is to prevent leaks and maintain the efficiency of various truck systems. Understanding its function and significance can contribute to better maintenance practices and operational efficiency in commercial truck fleets 1.

Basic Concepts of Sealing Washers

Sealing washers are mechanical components used to create a seal between two surfaces, typically in fluid systems. They operate by filling the gap between mating surfaces, thereby preventing the escape of fluids and the ingress of contaminants. This function is vital for maintaining system pressure, ensuring fluid purity, and preventing system failure due to leaks 2.

Purpose of the 3921376 Sealing Washer

The Cummins 3921376 Sealing Washer is specifically designed to play a role in the fluid systems of trucks. It is associated with components where fluid transfer or containment is necessary. By ensuring a tight seal, it helps in maintaining the operational integrity of these systems, contributing to the overall efficiency and reliability of the truck 3.

Key Features

The 3921376 Sealing Washer is characterized by its material composition, which is chosen for its durability and resistance to the fluids it encounters. Its design is tailored to fit precisely within the systems it is intended for, ensuring a reliable seal. Unique attributes may include specific dimensions or surface treatments that enhance its performance under operational conditions 4.

Benefits

Utilizing the Cummins 3921376 Sealing Washer offers several advantages. It contributes to improved system efficiency by ensuring that fluids are contained within their intended paths. This containment helps in maintaining system pressure and fluid purity, leading to enhanced operational reliability. Additionally, the washer’s design and material contribute to its longevity, reducing the frequency of replacements and maintenance interventions 5.

Installation and Usage

Proper installation of the 3921376 Sealing Washer is crucial for its effective function. It should be installed according to the manufacturer’s guidelines, ensuring that it is correctly positioned and not damaged during the process. Specific procedures may include cleaning the mating surfaces and inspecting the washer for any defects before installation 6.

Troubleshooting and Maintenance

Common issues with sealing washers may include leaks or washer failure due to wear or damage. Diagnostic procedures involve inspecting the washer and its mating surfaces for signs of wear, damage, or misalignment. Maintenance practices include regular inspection of the washer and its associated systems, ensuring that any signs of wear or leakage are addressed promptly to prevent system failure 7.

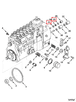

Compatibility and Application

The Cummins 3921376 Sealing Washer is designed for use in specific truck systems, where fluid containment and transfer are critical. It is compatible with certain models and components within these systems, ensuring that it meets the operational requirements and environmental conditions of its application 8.

Manufacturer Information - Cummins

Cummins is a renowned manufacturer in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. With a history of producing reliable and efficient components, Cummins has established a reputation for excellence in the industry. Their focus on research and development ensures that their products, including the 3921376 Sealing Washer, meet the high standards required for commercial truck operations 9.

Conclusion

The Cummins 3921376 Sealing Washer plays a significant role in maintaining the integrity and efficiency of fluid systems in commercial trucks. Its proper installation, maintenance, and understanding of its function contribute to the overall reliability and operational efficiency of truck fleets. Cummins’ commitment to quality and innovation ensures that this part meets the demanding requirements of commercial truck operations.

-

Smil, Vaclav. The History and Impact of Diesel Engines and Gas Turbines. The MIT Press, 2010.

↩ -

Schuetz, Thomas. Aerodynamics of Road Vehicles: Fifth Edition. SAE International, 2016.

↩ -

Harrison, Matthew. Controlling Noise and Vibration in Road Vehicles. SAE International, 2004.

↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines. McGraw-Hill, 2008.

↩ -

Cummins. Service Manual (4388708). QSF3.8 CM2350 F118.

↩ -

Cummins. Service Manual (4388708). QSF3.8 CM2350 F118.

↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines. McGraw-Hill, 2008.

↩ -

Cummins. Service Manual (4388708). QSF3.8 CM2350 F118.

↩ -

Cummins. Service Manual (4388708). QSF3.8 CM2350 F118.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.