3923096

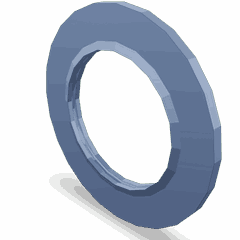

Sealing Washer

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

Minimum Quantity 3

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Sealing Washer 3923096 by Cummins is engineered to provide reliable sealing in various applications within commercial trucks. This component ensures the integrity of fluid systems by preventing leaks, thereby maintaining the efficiency and safety of truck operations 1.

Basic Concepts of Sealing Washers

Sealing washers are components designed to create a seal between two surfaces, preventing the leakage of fluids or gases. They are typically made from materials that offer durability, flexibility, and resistance to the substances they are intended to seal. In mechanical systems, these washers are essential for maintaining system pressure, ensuring fluid integrity, and protecting against contamination 2.

Role of Sealing Washer 3923096 in Truck Operation

The Sealing Washer 3923096 is utilized in various truck systems, including fuel, hydraulic, and cooling systems. It ensures that fluids are delivered efficiently without leakage, contributing to the consistent operation and overall performance of these systems 3.

Key Features

This Cummins part is constructed from high-quality materials that resist wear, corrosion, and specific fluids. Its design ensures a snug fit, providing a reliable seal. Additionally, it may feature anti-extrusion properties to prevent displacement under pressure.

Benefits

The use of the Sealing Washer 3923096 enhances system efficiency by ensuring fluid containment and delivery. Its durability and reliability extend the lifespan of the systems it serves, reducing the need for frequent replacements or repairs. The robust design of this part enhances overall truck reliability, minimizing downtime and maintenance costs.

Troubleshooting and Maintenance

Regular maintenance and troubleshooting are recommended to ensure the optimal performance and longevity of the Sealing Washer 3923096. Inspecting the washer for signs of wear, deformation, or damage can help identify potential issues before they lead to system failure. Replacing the washer at recommended intervals or when signs of degradation are observed can prevent leaks and maintain system integrity. Additionally, ensuring that connection points are clean and free of debris contributes to the effective functioning of the washer.

About Cummins

Cummins is a renowned manufacturer known for producing high-quality automotive components. With a history of innovation and commitment to excellence, Cummins has established itself as a trusted provider of parts that enhance the performance, efficiency, and reliability of commercial vehicles. Their products, including the Sealing Washer 3923096, are designed with precision and engineered to meet the demanding requirements of truck operations.

Compatibility of Cummins Sealing Washer Part 3923096

The Cummins sealing washer part number 3923096 is designed to fit seamlessly with a range of Cummins engines, ensuring optimal sealing and performance. This part is crucial for maintaining the integrity of the engine’s sealing systems, preventing leaks, and ensuring efficient operation.

Compatibility with Specific Engines

-

6B5.9 and B3.3 Engines The sealing washer part 3923096 is engineered to fit perfectly with the 6B5.9 and B3.3 engines. These engines are known for their robust design and reliability, and the washer ensures that the sealing components function as intended, contributing to the longevity and efficiency of the engine.

-

ISB CM550 and ISB CM850 Engines The ISB CM550 and ISB CM850 engines benefit from the precision fit of the sealing washer part 3923096. These engines are part of Cummins’ ISB series, which is renowned for its power and efficiency. The washer’s design ensures that the sealing systems in these engines operate smoothly, preventing any potential leaks that could compromise performance.

-

QSB5.9 CM850 Engine The QSB5.9 CM850 engine is another model that is compatible with the sealing washer part 3923096. This engine is designed for heavy-duty applications and requires reliable sealing to maintain its performance under demanding conditions. The washer ensures that the sealing systems in the QSB5.9 CM850 engine are airtight, contributing to its durability and efficiency.

By ensuring a proper fit and function, the sealing washer part 3923096 plays a critical role in the overall performance and reliability of these Cummins engines.

Role of Part 3923096 Sealing Washer in Engine Systems

The part 3923096 Sealing Washer is an essential component in ensuring the integrity and efficiency of various engine systems. Its primary function is to create a secure seal between different engine components, preventing leaks and maintaining system pressure.

Integration with Key Engine Components

Drain System

In the drain system, the Sealing Washer is positioned between the drain plug and the engine block. This placement ensures that oil and other fluids are effectively contained within the system during operation, and only released when the drain plug is manually removed for maintenance purposes.

Remote Oil System

For engines equipped with a remote oil system, the Sealing Washer is utilized at the connection points between the remote oil filter housing and the engine block. This seal is vital for maintaining the pressure within the oil system, ensuring that the oil filter operates efficiently and that clean oil is consistently circulated throughout the engine.

Housing and Flywheel

When installed in the housing that encases the flywheel, the Sealing Washer prevents oil leakage from the flywheel housing. This is particularly important in high-performance engines where oil pressure and temperature can vary significantly, potentially leading to leaks without proper sealing.

Long Block Assembly

In the long block assembly, which includes the cylinder block, crankshaft, pistons, and other core components, the Sealing Washer is used at various gasket interfaces. This ensures that coolant, oil, and other fluids remain within their designated pathways, preventing cross-contamination and maintaining the efficiency of the engine’s cooling and lubrication systems.

Oil Pan

The oil pan, which collects and stores engine oil, utilizes the Sealing Washer at the junction between the pan and the engine block. This seal is essential for containing the oil within the pan, ensuring that the oil level remains consistent and that the oil pump can effectively draw oil for circulation through the engine.

General Oil System

Throughout the oil system, the Sealing Washer is employed at numerous connection points, including those between the oil filter, oil galleries, and various sensor ports. This widespread use ensures that the oil system remains pressurized, allowing for optimal lubrication of moving parts and efficient heat dissipation.

Conclusion

The Sealing Washer 3923096 by Cummins is a critical component in maintaining the efficiency and reliability of commercial truck operations. Its role in preventing leaks and ensuring fluid integrity across various engine systems underscores its importance in the automotive industry. Regular maintenance and proper installation of this part are essential to maximize its benefits and ensure the longevity of the systems it serves.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.