4006239

Sealing Washer

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Sealing Washer 4006239 is a component manufactured by Cummins, a prominent entity in the commercial truck industry. This washer is specifically designed for use in commercial trucks, where it plays a role in ensuring the integrity and efficiency of various systems within the vehicle.

Basic Concepts of Sealing Washers

Sealing washers are mechanical components used to prevent leaks and maintain system integrity in various applications. They operate by creating a tight seal between two surfaces, which helps to contain fluids or gases within a system. This is important for the proper functioning of mechanical systems, as it ensures that the system operates efficiently and without unnecessary wear or damage 1.

Purpose of the 4006239 Sealing Washer

The 4006239 Sealing Washer is designed to serve a specific function within the operation of a truck. It is associated with systems or components where fluid or gas containment is necessary. By providing a reliable seal, it helps to maintain the efficiency and performance of these systems, ensuring that they operate as intended under various conditions 2.

Key Features

The 4006239 Sealing Washer boasts several key features that enhance its performance and durability. These include its material composition, which is chosen for its ability to withstand the pressures and temperatures encountered in truck operations. The design characteristics of the washer also contribute to its effectiveness, ensuring a secure and lasting seal. Additionally, any unique attributes of the washer, such as special coatings or treatments, further enhance its performance in demanding environments 3.

Benefits of Using the 4006239 Sealing Washer

Utilizing the 4006239 Sealing Washer offers several advantages. It contributes to improved system efficiency by ensuring that fluids or gases are contained within the system, reducing the risk of leaks. This not only enhances the performance of the truck but also extends the longevity of the associated components. Furthermore, the reliability of the washer under demanding conditions ensures that truck operations remain uninterrupted, providing peace of mind to operators and maintenance personnel alike 4.

Installation and Usage Guidelines

Proper installation of the 4006239 Sealing Washer is crucial for its optimal performance. This involves following a series of steps to ensure that the washer is correctly positioned and secured. Preparatory steps may include cleaning the surfaces where the washer will be installed to remove any debris or contaminants. The tools required for installation will depend on the specific application, but may include wrenches or specialized sealing tools. Best practices for installation include ensuring that the washer is not over-tightened, as this can lead to damage or reduced effectiveness 5.

Troubleshooting Common Issues

Common problems associated with sealing washers can include leaks, wear, or failure to create a secure seal. These issues may arise due to improper installation, exposure to extreme conditions, or natural wear over time. Recommended solutions or adjustments to rectify these issues may involve re-installing the washer, replacing it if it is worn or damaged, or adjusting the system to reduce pressure or temperature on the washer 6.

Maintenance Tips

Regular maintenance of the 4006239 Sealing Washer is important to ensure its continued effectiveness. This includes inspecting the washer at recommended intervals for signs of wear or failure, such as cracks, deformation, or leaks. If any issues are detected, the washer should be replaced or repaired as necessary. Additionally, following manufacturer guidelines for maintenance and replacement can help to extend the life of the washer and ensure optimal performance 7.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a rich history of producing reliable and efficient engines and components, Cummins has established a strong reputation among truck operators and maintenance professionals. The company’s product range includes a variety of parts and systems designed to enhance the performance and efficiency of commercial trucks, reflecting Cummins’ dedication to advancing the industry through technological innovation and superior craftsmanship 8.

Application in Cummins Engines

QSK78 Series

- QSK78 CM500

- The Sealing Washer 4006239 is utilized in the QSK78 CM500 engine to provide a reliable seal in areas where it is essential to prevent fluid or gas leakage. This part is typically found in components that require a tight seal to maintain operational efficiency and safety.

QSK60 Series

- QSK60 CM2350

- In the QSK60 CM2350 engine, the Sealing Washer 4006239 is employed in various sealing applications to ensure that no contaminants can enter sensitive areas of the engine. This helps in maintaining the engine’s performance and longevity by preventing wear and tear caused by leaks.

QSK50 Series

- QSK50 CM2300

- The Sealing Washer 4006239 is also integral to the QSK50 CM2300 engine, where it is used to secure and seal components that are critical for the engine’s operation. This part ensures that the engine operates smoothly and efficiently by preventing any unwanted leakage.

QSK38 Series

- QSK38 CM2350

- In the QSK38 CM2350 engine, the Sealing Washer 4006239 is used to maintain the integrity of seals in various engine components. This helps in ensuring that the engine runs reliably and efficiently by preventing leaks that could compromise performance.

QSK23 Series

- QSK23 CM2350

- The Sealing Washer 4006239 is also applicable in the QSK23 CM2350 engine, where it is used to provide a secure seal in critical areas. This part is essential for maintaining the engine’s operational efficiency and preventing any potential damage caused by leaks.

Importance of the Sealing Washer

The Sealing Washer 4006239 is a fundamental component in Cummins engines, ensuring that all critical areas are sealed properly. This helps in maintaining the engine’s performance, reliability, and longevity by preventing leaks and contamination. The use of high-quality materials and precise engineering ensures that this part performs reliably under various operating conditions 9.

Role of Part 4006239 Sealing Washer in Engine Components

The Part 4006239 Sealing Washer is integral to maintaining the integrity and efficiency of various engine components. Its primary function is to ensure a tight seal between mating surfaces, preventing leaks and maintaining pressure within the system.

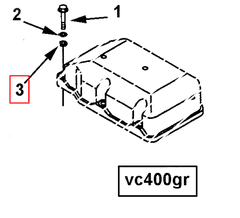

Valve Cover and Mounting

In the arrangement of the valve cover, the Sealing Washer is positioned between the valve cover and the mounting surface. This placement is essential for creating a barrier that prevents oil from escaping the valve cover area. The washer’s precise fit and material properties ensure that it can withstand the pressures and temperatures encountered in this part of the engine.

Valve and Cover Interface

At the interface between the valve and its cover, the Sealing Washer plays a significant role. It ensures that the valve operates within a sealed environment, which is necessary for optimal performance and longevity of the valve components. The washer helps in maintaining the correct pressure and preventing contaminants from entering the valve area.

Head Gasket Set

When incorporated into a single head gasket set, the Sealing Washer contributes to the overall sealing solution provided by the gasket. It fills any minor imperfections or gaps that may exist between the head and the block, enhancing the gasket’s ability to prevent coolant and oil leaks. This is particularly important in high-performance engines where even the smallest leak can lead to significant issues.

Upper Engine Gasket Kit

In an upper engine gasket kit, the Sealing Washer is often included to address specific sealing challenges presented by the upper components of the engine. It complements other gaskets and seals within the kit, providing a comprehensive sealing solution that covers a range of interfaces and connections.

Overall, the Part 4006239 Sealing Washer is a versatile component that enhances the functionality and reliability of various engine systems by ensuring effective seals at critical interfaces.

Conclusion

The 4006239 Sealing Washer by Cummins is a critical component in the maintenance and operation of several Cummins engine models. Its role in preventing leaks and maintaining system integrity is essential for the efficient and reliable operation of commercial trucks. Proper installation, regular maintenance, and understanding its application in various engine components are key to maximizing the benefits of this part.

-

Trzesniowski, Michael. The Complete Vehicle. Springer Nature, 2023.

↩ -

Asef, Pedram, Sanjeevikumar Padmanaban, and Andrew Lapthorn. Modern Automotive Electrical Systems. Wiley, 2022.

↩ -

Dixon, John C. Tyres Suspension and Handling Second Edition. SAE International, 1996.

↩ -

Kershaw, John F. SAE International’s Dictionary for Automotive Engineers. SAE International, 2023.

↩ -

Cummins Inc. Service Manual (5613073).

↩ -

Cummins Inc. Service Manual (5613073).

↩ -

Cummins Inc. Service Manual (5613073).

↩ -

Cummins Inc. Service Manual (5613073).

↩ -

Cummins Inc. Service Manual (5613073).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.