This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

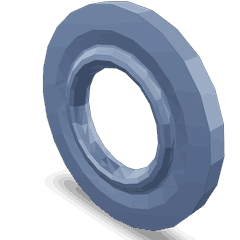

The Cummins 4010801 Sealing Washer is a specialized component designed for commercial truck applications. It ensures system integrity by preventing leaks and maintaining pressure, contributing to the efficient and reliable performance of commercial trucks 1.

Basic Concepts of Sealing Washers

Sealing washers are mechanical components that prevent fluid leaks and maintain system pressure. They are placed between two surfaces that need to be sealed, such as pipe fittings or engine components. By creating a tight seal, these washers ensure that fluids or gases do not escape, which is vital for the proper operation of many systems, including fuel, hydraulic, and cooling systems 2.

Purpose of the 4010801 Sealing Washer

The 4010801 Sealing Washer is designed to enhance the operation of commercial trucks. It is used in various systems such as fuel, hydraulic, and cooling systems to prevent leaks and maintain pressure. This washer ensures that these systems function efficiently, which is important for the overall performance and reliability of the truck 3.

Key Features

The 4010801 Sealing Washer is characterized by its material composition and design. It is typically made from durable materials that can withstand high pressure and temperature, ensuring long-lasting performance. The design of the washer may include specific features that enhance its sealing capabilities, such as a particular shape or texture that allows it to conform to the surfaces it seals.

Benefits

Using the 4010801 Sealing Washer provides several benefits. It contributes to improved system efficiency by ensuring that fluids or gases remain contained within the system. This can lead to reduced maintenance requirements, as the washer helps to prevent leaks that could otherwise cause damage or require frequent repairs. Additionally, the washer enhances the reliability of the systems it is used in, which is important for the consistent performance of commercial trucks.

Installation Guidelines

Proper installation of the 4010801 Sealing Washer is important to ensure optimal performance and longevity. Installation should follow manufacturer guidelines, which may include specific torque settings for tightening fittings and ensuring that the washer is properly seated. It is also important to inspect the washer for any damage before installation and to use the correct size washer for the application.

Troubleshooting Common Issues

Common problems associated with sealing washers include leaks or failure. If a leak is detected, it may be necessary to inspect the washer for damage or wear. Replacing the washer can often resolve the issue. It is also important to ensure that the washer is correctly installed and that the surfaces it seals are clean and free from debris.

Maintenance Tips

Routine maintenance practices can help to prolong the lifespan of the 4010801 Sealing Washer. This may include regular inspection intervals to check for signs of wear or damage, cleaning the washer and the surfaces it seals to remove any buildup, and replacing the washer according to manufacturer guidelines or when signs of wear are detected.

Application with Engine Models

QSV81G and QSV91G Engines

The 4010801 Sealing Washer is specifically designed to fit the QSV81G and QSV91G engines. These engines benefit from the washer’s precision fit, which helps in maintaining optimal performance and longevity. The washer’s material and design ensure it can withstand the high pressures and temperatures typical of these engines.

QSW/QSV82 Engines

For the QSW/QSV82 engines, the 4010801 Sealing Washer is equally important. Its design allows for a snug fit that prevents any potential fluid or gas leaks, which is critical for the engine’s efficiency and safety. The washer’s compatibility with these engines ensures that it can handle the specific demands placed on it.

QSW73 Engines

The 4010801 Sealing Washer also fits the QSW73 engines. This part’s design is tailored to meet the unique requirements of these engines, providing a reliable seal that enhances the overall performance and durability of the engine. The washer’s ability to maintain a tight seal is essential for the efficient operation of the QSW73 engines.

Role of 4010801 Sealing Washer in Engine Systems

The 4010801 Sealing Washer is an essential component in ensuring the integrity and efficiency of various engine systems. When integrated into the cooler system, this sealing washer plays a significant role in maintaining the pressure and preventing leaks within the cooling circuits. It ensures that the coolant flows smoothly without any interruptions, which is vital for maintaining optimal engine temperature.

In the engine oil system, the 4010801 Sealing Washer is employed to create a tight seal between moving parts, such as within the oil pump or between the oil filter housing and the engine block. This seal is important for maintaining oil pressure, which is necessary for lubricating engine components and reducing wear and tear.

Furthermore, within the oil assembly cooler, the 4010801 Sealing Washer helps in securing the connections between the cooler and the oil lines. This ensures that oil is effectively cooled before it re-enters the engine, which enhances the overall performance and longevity of the engine components. The washer’s ability to form a reliable seal under varying temperatures and pressures makes it a valuable component in this application.

Conclusion

The Cummins 4010801 Sealing Washer is a critical component for maintaining the efficiency and reliability of commercial truck engines. Its proper installation, regular maintenance, and correct application across various engine models ensure that it continues to perform its intended function effectively. By understanding the role and benefits of this part, truck operators and maintenance personnel can ensure the longevity and optimal performance of their vehicles.

-

Eret, Angelina. Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature, 2024.

↩ -

Duffy, Owen C, and Gus Wright. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩ -

Taghavifar, Hamid, and Aref Mardani. Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer, 2017.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.