This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4318977 Sealing Washer is a component designed to ensure the integrity of fluid and pressure systems in commercial trucks. Its role is significant in maintaining the operational efficiency and reliability of truck systems by providing effective sealing solutions.

Basic Concepts of Sealing Washers

Sealing washers are mechanical components used to prevent leaks in fluid and pressure systems. They function by creating a barrier that prevents the escape of fluids or gases, thereby maintaining system pressure and ensuring the smooth operation of mechanical systems. In the context of trucks, sealing washers contribute to the overall integrity of the vehicle’s fluid systems, including fuel, coolant, and hydraulic systems 1.

Purpose of the 4318977 Sealing Washer

This Cummins part is specifically designed to play a role in various truck systems by ensuring that connections remain sealed under pressure. It is applied in systems where fluid transfer occurs, such as in fuel lines, coolant systems, and hydraulic circuits. By maintaining a seal, it helps in preserving system efficiency and preventing fluid loss 2.

Key Features

The 4318977 Sealing Washer is characterized by its material composition, which is selected for durability and resistance to the specific fluids it encounters. Its design specifications include precise dimensions to ensure a snug fit in the intended applications. Unique characteristics may include enhanced flexibility or resistance to extreme temperatures, which contribute to its performance in demanding truck environments.

Benefits of Using the 4318977 Sealing Washer

Utilizing this part offers several advantages. It provides improved sealing efficiency, which is vital for maintaining system pressure and preventing leaks. Its durability ensures long-term reliability, reducing the frequency of replacements. Additionally, its design contributes to the overall reliability of truck operations by ensuring that fluid systems function as intended.

Installation Guidelines

Proper installation of the 4318977 Sealing Washer involves several steps to ensure optimal performance. It should be placed correctly within the system, ensuring that it is not twisted or misaligned. Care should be taken to avoid damaging the washer during installation. Following manufacturer guidelines for torque specifications when tightening fittings is also important to maintain the integrity of the seal.

Troubleshooting Common Issues

Common issues with sealing washers include leaks or failures, which can often be traced back to improper installation or wear and tear. Addressing these issues may involve inspecting the washer for signs of damage, ensuring it is correctly installed, or replacing it if necessary. Regular checks can help identify potential problems before they lead to system failures.

Maintenance Tips

Regular maintenance of the 4318977 Sealing Washer is key to prolonging its lifespan and ensuring consistent performance. This includes periodic inspection for signs of wear or damage and adhering to recommended replacement schedules. Keeping the washer and its surrounding components clean can also contribute to its longevity and effectiveness.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and history of excellence make it a trusted name in the industry.

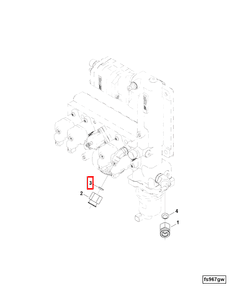

Cummins Engine Part 4318977: Sealing Washer Application

The Cummins part number 4318977, a Sealing Washer, is a critical component used across a variety of Cummins engine models. This part is designed to provide a secure and leak-proof seal in various applications within the engine system. Below is a detailed description of how this sealing washer fits into the specified Cummins engines.

ISM Series Engines

The ISM series engines, including the ISM CM570, ISM CM876, and ISM11 CM876 SN, utilize the sealing washer in several key areas. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The sealing washer ensures that connections between different parts of the engine remain tight and leak-free, contributing to the overall efficiency and longevity of the engine.

ISX Series Engines

The ISX series engines, such as the ISX CM570, ISX CM870, ISX CM871, and ISX15 CM2250, also incorporate the sealing washer in various critical junctures. These engines are designed for high-performance applications, and the sealing washer plays a vital role in maintaining the integrity of the engine’s connections. The ISX15 CM2250 SN and ISX15 CM2350 X101 models, in particular, benefit from the sealing washer’s ability to prevent leaks and ensure smooth operation.

ISX15 Series Engines

The ISX15 series engines, including the ISX15 CM2250, ISX15 CM2250 SN, and ISX15 CM2350 X101, are equipped with the sealing washer in numerous applications. These engines are engineered for demanding environments, and the sealing washer is essential in maintaining the engine’s performance and reliability. Its role in preventing leaks and securing connections is crucial for the efficient operation of these engines.

QSX15 Series Engines

The QSX15 series engines, such as the QSX15 CM2250 ECF and QSX15 CM2350 X105, also utilize the sealing washer. These engines are designed for applications requiring high power and efficiency, and the sealing washer ensures that all connections within the engine remain secure and leak-proof. This is particularly important in maintaining the engine’s performance under various operating conditions.

X15 Series Engines

The X15 series engines, including the X15 CM2350 X116B, X15 CM2350 X123B, and X15 CM2450 X134B, incorporate the sealing washer in several key areas. These engines are built for durability and performance, and the sealing washer is essential in ensuring that all connections within the engine system remain tight and leak-free. This contributes to the overall reliability and efficiency of the engine.

Role of Part 4318977 Sealing Washer in Engine Systems

Fuel System Integration

In the fuel system, the 4318977 Sealing Washer is instrumental in maintaining the integrity of fuel lines and connections. It ensures that fuel is delivered to the engine without leaks, which is essential for efficient combustion and overall engine performance. The washer is placed between the fuel injector and the fuel rail, creating a tight seal that prevents fuel from escaping. This not only enhances the efficiency of fuel delivery but also contributes to the safety of the system by minimizing the risk of fuel leaks.

Accessories Component Functionality

When it comes to engine accessories, the 4318977 Sealing Washer plays a significant role in the operation of components such as the fuel pump and various sensors. It is often used in the connections of these accessories to ensure that fluids and gases are contained within the system. For instance, in the fuel pump assembly, the washer seals the connection points, ensuring that the fuel pump operates efficiently without any loss of pressure. Similarly, in sensor connections, it helps maintain the accuracy of readings by preventing any external contaminants from entering the system.

Overall System Reliability

The consistent use of the 4318977 Sealing Washer across different engine systems underscores its importance in maintaining system reliability. By ensuring that connections are sealed properly, it contributes to the longevity and performance of both the fuel system and engine accessories. This, in turn, leads to a more robust and dependable engine operation, reducing the likelihood of unexpected failures and enhancing the overall efficiency of the engine.

Conclusion

The Cummins 4318977 Sealing Washer is a vital component in the maintenance and operation of commercial truck systems. Its role in preventing leaks and securing connections across various engine models ensures the reliability and efficiency of truck operations. Proper installation, regular maintenance, and understanding its application in different engine systems are key to maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.