This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

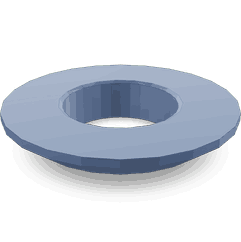

The 4325478 Spherical Washer is a component manufactured by Cummins, a well-established name in the commercial truck industry. This washer is specifically designed for use in commercial trucks, where it contributes to the efficient operation of various mechanical systems.

Basic Concepts of Spherical Washers

Spherical washers are mechanical components characterized by their dome-shaped design. Unlike flat washers, which have a uniform thickness, spherical washers feature a curved surface. This design allows them to distribute loads more evenly across a surface and reduce friction between moving parts. They are commonly used in applications where components are subject to dynamic loads or where precise alignment is required 1.

Purpose of the 4325478 Spherical Washer

In the context of a commercial truck, the 4325478 Spherical Washer plays a role in distributing loads and reducing friction between components. By doing so, it helps to maintain the integrity of mechanical systems under the demanding conditions typically encountered in heavy-duty applications. Its design allows for better load distribution, which can lead to improved performance and longevity of the associated components 2.

Key Features

The 4325478 Spherical Washer is engineered with specific design elements that make it suitable for heavy-duty applications. These include a material composition that offers high strength and resistance to wear, a load-bearing capacity that meets the demands of commercial truck operations, and dimensional accuracy that ensures proper fit and function within the mechanical system.

Benefits

Using the 4325478 Spherical Washer provides several advantages. Its design contributes to enhanced durability, allowing it to withstand the rigors of heavy-duty use. It also offers improved performance under stress, helping to maintain system efficiency. Additionally, its construction ensures longevity even in harsh operating conditions, making it a reliable component for commercial trucks 3.

Installation Considerations

Proper installation of the 4325478 Spherical Washer is important for ensuring optimal performance and longevity. Guidelines for installation include adhering to specified torque values to avoid over-tightening, which could damage the washer or the components it interfaces with. Alignment is also critical, as the spherical shape of the washer requires precise positioning to function as intended.

Troubleshooting and Maintenance

Common issues with spherical washers can include wear and deformation under load. Identifying these problems early can help prevent more significant mechanical issues. Maintenance practices for the 4325478 Spherical Washer include regular inspection for signs of wear or damage and replacement as necessary to ensure continued system performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes a variety of components and systems designed to meet the needs of heavy-duty applications, underscoring its commitment to excellence and customer satisfaction.

Cummins Spherical Washer 4325478 in Engine Applications

The Cummins Spherical Washer part number 4325478 is a critical component in various engine configurations, ensuring proper sealing and alignment. This washer is designed to fit seamlessly within the engine systems, providing a reliable interface between moving parts.

ISV (Nissan) Engines

In the ISV engines manufactured by Nissan, the spherical washer 4325478 plays a pivotal role in maintaining the integrity of the engine’s operation. This washer is typically used in areas where spherical motion is required, such as in valve assemblies or other rotating components. Its design allows for smooth rotational movement while maintaining a tight seal, which is essential for the engine’s performance and longevity.

The washer’s ability to conform to different surfaces ensures that it can adapt to the specific requirements of the engine, providing consistent performance under varying conditions. This adaptability is crucial in high-stress environments where the engine operates, ensuring that the washer does not wear out prematurely or cause misalignment.

In summary, the Cummins Spherical Washer 4325478 is a vital part in the ISV engines, contributing to the overall efficiency and reliability of the engine by ensuring proper sealing and alignment in critical areas.

Role of Part 4325478 Spherical Washer in Engine Systems

In the intricate assembly of engine systems, part 4325478 Spherical Washer serves a significant function by ensuring the smooth operation and longevity of various components.

Integration with the Camshaft

When installed in conjunction with the camshaft, the Spherical Washer aids in maintaining precise valve timing. It does this by providing a consistent and even distribution of load across the camshaft bearings. This reduces friction and wear, contributing to the camshaft’s efficient performance over time.

Contribution to Injector Functionality

In fuel injection systems, the Spherical Washer plays a role in securing the injector to the engine block or cylinder head. It ensures a tight and leak-free seal, which is essential for maintaining fuel pressure and delivering accurate fuel quantities to the combustion chamber. This precision is vital for optimal engine performance and fuel efficiency.

Role in Long Block Kit Assembly

Within a long block kit, which typically includes the engine block, crankshaft, pistons, and camshaft, the Spherical Washer is often used in the assembly of the camshaft bearings. Its spherical shape allows for minor adjustments in alignment, which is crucial during the initial setup and subsequent maintenance of the engine. This flexibility helps in achieving the correct clearances and tolerances necessary for the engine’s reliable operation.

General Application in Engine Parts

Across various engine parts, the Spherical Washer is employed where components need to be secured yet allow for some degree of movement or adjustment. Its design mitigates stress concentrations and enhances the durability of the parts it connects. This is particularly beneficial in high-performance engines where components are subjected to greater stresses and thermal cycles.

Enhancing Performance

In performance-oriented engine builds, the Spherical Washer is often selected for its ability to reduce friction and wear in critical moving parts. This not only enhances the engine’s efficiency but also contributes to its overall longevity, making it a preferred choice among enthusiasts and professional mechanics alike.

Conclusion

The 4325478 Spherical Washer is a vital component in the operation of commercial trucks and engines, offering benefits such as load distribution, reduced friction, and enhanced durability. Proper installation and maintenance are key to ensuring its effectiveness and longevity in heavy-duty applications.

-

Harrison, Matthew. Controlling Noise and Vibration in Road Vehicles. SAE International, 2004.

↩ -

Richards, Paul, and Jim Barker. Automotive Fuels Reference Book. SAE International, 2023.

↩ -

Duffy, Owen C, and Gus Wright. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.