This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

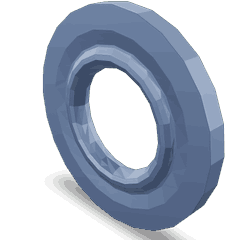

The Sealing Washer 4358040, manufactured by Cummins, is a critical component in the automotive and heavy-duty truck industries. Designed for heavy-duty truck applications, this part ensures the integrity and efficiency of various systems within the vehicle.

Basic Concepts of Sealing Washers

Sealing washers are mechanical components that prevent leaks and maintain system integrity in various applications. They create a tight seal between two surfaces, typically where fluids or gases are present, ensuring systems operate efficiently and without contamination 1.

Purpose of the 4358040 Sealing Washer

The 4358040 Sealing Washer is designed for the demanding environment of heavy-duty trucks. It is associated with systems where fluid or gas sealing is crucial. By providing a reliable seal, it contributes to the overall efficiency and reliability of the truck’s systems, preventing leaks that could lead to system failure or inefficiency 2.

Key Features

The 4358040 Sealing Washer features a material composition chosen for its ability to withstand high pressures and temperatures encountered in heavy-duty truck applications. Its design, including shape and size, is tailored to fit precisely within the systems it is intended for, ensuring a tight and effective seal. Unique attributes, such as special coatings or treatments, further enhance its performance in challenging conditions 3.

Benefits

The advantages of the 4358040 Sealing Washer include improved system efficiency, reduced maintenance requirements, and enhanced reliability in truck operations. By ensuring a tight seal, it maintains the integrity of the systems it is part of, leading to more efficient operation and reduced risk of leaks. This results in lower maintenance requirements and increased reliability, making it a valuable component in heavy-duty truck applications 4.

Installation and Usage

Proper installation and usage of the 4358040 Sealing Washer are crucial for optimal performance. Guidelines for installation should be followed carefully, including ensuring surfaces are clean and free from debris before installation, using the correct tools for installation, and checking the seal after installation to ensure it is effective 5.

Troubleshooting and Maintenance

Common issues with the 4358040 Sealing Washer may include leaks or failure to seal effectively. Troubleshooting these issues may involve checking the washer for signs of wear or damage, ensuring it is correctly installed, and verifying that the surfaces it seals against are in good condition. Maintenance practices to prolong the service life of the washer include regular inspection for signs of wear, cleaning the surfaces it seals against, and replacing the washer as necessary to ensure continued effectiveness 6.

Cummins Overview

Cummins is a renowned manufacturer in the automotive and heavy-duty truck industries, known for producing high-quality components and systems. Their product range includes a wide variety of parts and systems designed for use in heavy-duty applications, where reliability and efficiency are paramount. Cummins’ reputation is built on a foundation of quality, innovation, and customer satisfaction, making them a trusted name for professionals in the field 7.

Cummins Sealing Washer 4358040 Compatibility

The Cummins Sealing Washer part number 4358040 is designed to fit seamlessly within the operational framework of several Cummins engine models. This part is integral to ensuring the integrity of the engine’s sealing system, which is crucial for maintaining optimal performance and preventing leaks.

QSK50 Engine

In the QSK50 engine, the sealing washer 4358040 is utilized in various critical applications. It is essential for the proper sealing of components that are subject to high pressure and temperature, ensuring that the engine operates efficiently and reliably.

CM2150 and MCRS Engines

For the CM2150 and MCRS engines, the sealing washer 4358040 serves a similar purpose. These engines, known for their robust construction and performance, rely on this part to maintain the integrity of their sealing systems. The washer’s design allows it to withstand the demanding conditions within these engines, providing a dependable seal that is vital for their operation.

Grouping of Engines

The CM2150 and MCRS engines, while distinct in their specific applications, share a commonality in their requirement for high-performance sealing solutions. The use of the sealing washer 4358040 in these engines underscores the importance of precision engineering in maintaining engine efficiency and longevity.

Role of Part 4358040 Sealing Washer in Engine Systems

In the context of engine systems, the 4358040 Sealing Washer ensures the integrity and efficiency of various assemblies. Its application spans across multiple components, each playing a specific role in the overall functionality of the engine.

Integration with the Arrangement

The arrangement of components within an engine system is meticulously designed to optimize performance and reliability. The 4358040 Sealing Washer is employed in this arrangement to prevent leaks between mating surfaces. By ensuring a tight seal, it maintains the structural integrity of the assembly, allowing for consistent operation under varying conditions.

Function in the Pressure Regulator Valve

The Pressure Regulator Valve (PRV) is a component that controls the pressure of fluids within the engine system. The 4358040 Sealing Washer is integral to the PRV, as it seals the interface between the valve body and the diaphragm. This seal is essential for maintaining the desired pressure levels, ensuring that the engine operates within specified parameters. Without this washer, pressure fluctuations could occur, leading to inefficient engine performance.

Role in the Control Panel

The Control Panel is the nerve center of the engine system, housing various sensors and actuators that monitor and regulate engine functions. The 4358040 Sealing Washer is used in the control panel to seal connections between sensors, actuators, and the panel itself. This ensures that electrical connections remain secure and that there are no unintended shorts or opens in the circuit, which could compromise the control panel’s functionality.

Application in the Fuel Transfer Kit

The Fuel Transfer Kit is designed to move fuel from one location to another within the engine system. The 4358040 Sealing Washer is utilized in this kit to seal connections between fuel lines and components such as pumps and filters. This seal is vital for preventing fuel leaks, which could pose a safety hazard and lead to inefficient fuel delivery to the engine. By maintaining a secure seal, the washer ensures that the fuel transfer process is smooth and reliable.

Conclusion

The 4358040 Sealing Washer plays a significant role in maintaining the efficiency and safety of engine systems by ensuring secure seals in various components. Its application across the arrangement, pressure regulator valve, control panel, and fuel transfer kit underscores its importance in the overall functionality of the engine.

-

Sully, F. K. (1998). Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing.

↩ -

Osgood, L., Cameron, G., & Christensen, E. (2024). Engineering Mechanics: Statics. Creative Commons.

↩ -

Van Gelder, K. T. (2018). Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning.

↩ -

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Cummins. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 4383852.

↩ -

Cummins. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 4383852.

↩ -

Cummins. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 4383852.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.