This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4391828 Lock Washer is a component manufactured by Cummins, a well-established name in the commercial truck industry. This Cummins part is designed for use in fastening systems within commercial trucks, where it contributes to the secure attachment of various components. Lock washers, in general, play a role in preventing the loosening of fasteners, which is vital for the safety and reliability of mechanical assemblies 1.

Basic Concepts of Lock Washers

Lock washers are mechanical devices used in conjunction with bolts and nuts to prevent loosening due to vibration or other dynamic forces. They achieve this by applying additional pressure to the fastener or by creating a spring-like tension that resists movement. In mechanical assemblies, lock washers are integral to maintaining the integrity of bolted joints, ensuring that components remain securely fastened under various operating conditions 2.

Purpose of the 4391828 Lock Washer

This part is specifically designed to enhance the fastening systems in commercial trucks. It is utilized in environments where vibrations and dynamic loads are common, such as in the drivetrain, engine mounts, and other critical areas of the vehicle. This lock washer helps to maintain the tightness of fasteners, which is crucial for the operation and maintenance of commercial trucks, ensuring components remain securely in place throughout the vehicle’s service life.

Key Features

The 4391828 is characterized by its robust design and material composition, which typically includes high-strength steel. This material choice ensures durability and resistance to wear. The design of the washer may include serrated edges or a split configuration, which provides the necessary tension to keep fasteners secure. These features contribute to the washer’s performance and longevity, especially in demanding applications.

Benefits

Utilizing this Cummins part offers several advantages. It provides improved fastening security by preventing the loosening of bolts and nuts, which is particularly beneficial in applications subject to vibration. Additionally, its design enhances resistance to dynamic forces, contributing to the overall reliability of the fastening system. The durability of the washer ensures longevity, even in harsh operating conditions, reducing the need for frequent replacements.

Installation Guidelines

Proper installation of the 4391828 is key to ensuring optimal performance and safety. It should be placed under the head of the bolt or nut, with the serrated or split side facing the fastening surface. This orientation maximizes the washer’s ability to resist movement. It is also important to pair the lock washer with the appropriate fasteners and to use the correct tools for installation to avoid damage and ensure a secure fit.

Troubleshooting and Maintenance

Common issues with lock washers include deformation or failure due to excessive force or corrosion. Regular inspection for signs of wear or damage is recommended to identify potential problems early. Maintenance practices, such as cleaning and applying a protective coating, can prolong the life of the 4391828 and ensure continued reliable performance. Replacing worn or damaged washers promptly is crucial to maintaining the integrity of the fastening system.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to excellence is evident in its wide range of products, including components like the 4391828, which are designed to meet the demanding requirements of commercial vehicles. Cummins’ focus on quality and innovation ensures that its components contribute to the reliability and performance of commercial trucks worldwide 3.

Role of the 4391828 Lock Washer in Engine Systems

This part is an essential component in ensuring the secure and reliable operation of various engine systems. Its primary function is to prevent loosening of fasteners under vibration and thermal expansion, which are common in engine environments.

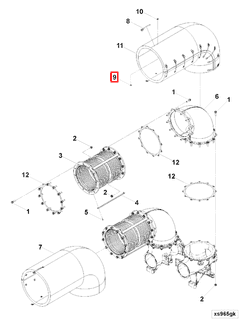

Aftertreatment Device

In the aftertreatment device, the 4391828 is used to secure connections between the device and the exhaust system. This ensures that the aftertreatment device remains firmly attached, maintaining the integrity of the emissions control system.

Turbocharger

Within the turbocharger arrangement, the lock washer is employed at critical connection points. It helps to maintain the tightness of bolts and nuts that secure the turbocharger to the engine, preventing any unwanted movement that could lead to performance issues or damage.

Exhaust Outlet

At the exhaust outlet, the 4391828 plays a role in securing the connection between the exhaust manifold and the exhaust pipe. This is vital for maintaining a sealed exhaust path, which is necessary for efficient engine operation and reduced emissions.

Connection Insulation

In systems where connection insulation is required, such as around the decomposition reactor, the lock washer ensures that insulated connections remain tight. This is important for maintaining the thermal efficiency of the system and protecting surrounding components from heat.

Decomposition Reactor

Within the decomposition reactor, the lock washer is used to secure flanges and connections. This ensures that the reactor maintains a sealed environment, which is essential for the chemical processes occurring within it.

Heat Shield

The heat shield, which protects various engine components from excessive heat, utilizes the 4391828 to secure its attachment points. This ensures that the heat shield remains in place and effectively performs its protective function.

Reactor

In the reactor component of the engine system, the lock washer is crucial for securing connections that are exposed to high temperatures and pressures. This ensures the reactor operates within specified parameters, contributing to the overall efficiency and safety of the engine system.

By incorporating the 4391828 into these engine components, engineers and mechanics can ensure that connections remain secure under the demanding conditions of engine operation, thereby enhancing the reliability and performance of the engine system.

Conclusion

The 4391828 Lock Washer, manufactured by Cummins, plays a significant role in the secure and reliable operation of commercial truck engines and various engine systems. Its design and material composition are optimized to withstand the operational conditions of demanding applications, ensuring durability and performance. Proper installation, regular maintenance, and prompt replacement of worn or damaged washers are essential practices to maintain the integrity of fastening systems and ensure the safe and efficient operation of commercial vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.