This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Sealing Washer 4894467 is a component produced by Cummins, designed specifically for use in commercial truck operations. This washer plays a role in maintaining the integrity of various truck systems by providing a seal that prevents leaks and ensures efficient operation. Its design and material composition are tailored to withstand the demanding conditions encountered in heavy-duty truck environments 1.

Basic Concepts of Sealing Washers

Sealing washers are mechanical components used to create a seal between two surfaces, typically to prevent fluid or gas leakage. They function by filling the gap between mating surfaces, ensuring that the system remains closed and operates efficiently. In mechanical systems, sealing washers are vital for maintaining pressure, preventing contamination, and ensuring the longevity of the system components 2.

Purpose of Sealing Washer 4894467

The Sealing Washer 4894467 is employed in various truck systems where sealing is required to maintain system efficiency and prevent leaks. It is commonly used in fuel systems, hydraulic systems, and engine components. By providing a reliable seal, this washer helps in maintaining the pressure and purity of fluids within these systems, which is crucial for the optimal performance of the truck 3.

Key Features

The Sealing Washer 4894467 is characterized by its robust material composition, typically made from high-quality rubber or synthetic materials that offer resistance to wear, chemical exposure, and temperature variations. Its design includes precise dimensions to ensure a perfect fit in the intended applications, and it may feature unique properties such as anti-extrusion elements to enhance performance under pressure.

Benefits of Using Sealing Washer 4894467

Incorporating the Sealing Washer 4894467 into truck systems offers several advantages. It contributes to improved system efficiency by ensuring seals are maintained under various operating conditions. The washer’s durability and resistance to environmental factors lead to increased longevity of the components it protects. Additionally, its reliable performance enhances the overall reliability of the truck’s systems, reducing the likelihood of unexpected failures.

Installation and Usage Guidelines

Proper installation of the Sealing Washer 4894467 involves several steps to ensure it functions correctly. Begin by cleaning the mating surfaces to remove any debris or old sealant. Inspect the washer for any damage before installation. Use the appropriate tools to install the washer, ensuring it is seated correctly without distortion. Follow manufacturer guidelines for torque specifications if applicable.

Maintenance Tips

To ensure the Sealing Washer 4894467 continues to perform optimally, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage, and replacement as necessary. Keeping the mating surfaces clean and free of contaminants will also help maintain the integrity of the seal. Adhering to recommended replacement intervals can prevent unexpected failures and extend the lifespan of the truck’s systems.

Troubleshooting Common Issues

Common issues with sealing washers may include leaks, extrusion under pressure, or failure due to wear and tear. Identifying the root cause is key to resolving these problems. Inspecting the washer for physical damage, ensuring correct installation, and checking for compatibility with the system fluids and operating conditions are important steps in troubleshooting. Replacement with a compatible washer may be necessary to restore system integrity.

Manufacturer Overview - Cummins

Cummins is a renowned manufacturer in the commercial truck industry, known for its wide range of high-quality engine and component products. With a history of innovation and commitment to excellence, Cummins has established a strong reputation for producing reliable and efficient parts that meet the demanding requirements of heavy-duty truck operations. Their product range includes engines, filtration systems, and aftermarket parts, all designed to enhance the performance and longevity of commercial vehicles.

Sealing Washer Part 4894467 in Cummins Engines

The Sealing Washer part 4894467, manufactured by Cummins, is a critical component in ensuring the integrity and performance of various engine systems. This part is designed to fit seamlessly within the engine architecture of the ISBE CM800 and the QSB4.5 CM850 (CM2850) engines.

In the ISBE CM800 engine, the sealing washer is utilized in areas where it is essential to prevent leaks and maintain pressure, ensuring the engine operates efficiently and reliably. The part’s precision engineering guarantees a perfect fit, providing a robust seal that withstands the rigors of engine operation.

Similarly, in the QSB4.5 CM850 (CM2850) engines, the sealing washer part 4894467 plays a vital role in maintaining the engine’s performance. Its design allows it to adapt to the specific needs of these engines, ensuring that all seals are tight and secure, preventing any potential fluid or air leaks.

The compatibility of the sealing washer with these engines highlights Cummins’ commitment to providing high-quality, reliable parts that enhance engine longevity and performance. The part’s design and material ensure it can endure the demanding conditions within the engine, contributing to the overall efficiency and durability of the engine systems.

Role of Part 4894467 Sealing Washer in Engine Systems

In the context of engine systems, the part 4894467 Sealing Washer is instrumental in ensuring the integrity and efficiency of various components.

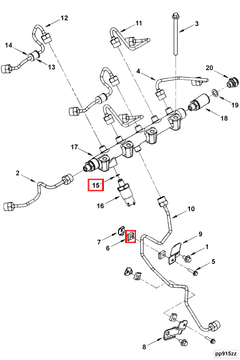

Fuel Manifold

Within the fuel manifold, the Sealing Washer is positioned to create a tight seal between the manifold and its connecting components. This ensures that fuel is delivered consistently and without leaks, maintaining the desired fuel pressure and flow rate essential for optimal engine performance.

Injector Plumbing

In the injector plumbing system, the Sealing Washer is utilized at connection points to prevent fuel leakage. This is vital for maintaining the precision of fuel delivery to each injector, which directly impacts combustion efficiency and overall engine performance.

General Plumbing

Across various plumbing connections within the engine system, the Sealing Washer serves to seal joints and fittings. This prevents fluid leaks, whether it be fuel, coolant, or oil, ensuring that each system operates within its designed parameters without contamination or loss of pressure.

Injector

At the injector itself, the Sealing Washer is often found where the injector meets the fuel rail or the engine block. Its role here is to ensure a secure seal, preventing fuel from escaping and ensuring that the injector receives a consistent supply of fuel under the correct pressure.

Pressure Sensor

In applications involving pressure sensors, the Sealing Washer is used to seal the sensor to its mounting point. This ensures accurate pressure readings by preventing any bypassing of fluids around the sensor, which could lead to incorrect data and potentially affect engine management decisions.

Upper Engine Gasket Set

Within the upper engine gasket set, the Sealing Washer complements the gaskets by providing additional sealing at specific points where gaskets alone may not suffice. This is particularly important in areas exposed to high pressure or temperature, ensuring the engine’s upper components remain sealed against leaks.

The strategic placement of the Sealing Washer across these components underscores its importance in maintaining the operational integrity and efficiency of engine systems.

Conclusion

The Sealing Washer 4894467 by Cummins is a vital component in the maintenance and operation of commercial truck engines. Its role in preventing leaks, maintaining pressure, and ensuring the efficiency of various engine systems cannot be overstated. Proper installation, regular maintenance, and understanding its application across different engine components are key to maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.