This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4899824 Sealing Washer is a component designed to ensure the proper functioning of commercial trucks. Its purpose is to provide a secure seal in various truck systems, preventing leaks and ensuring efficient operation. This sealing washer is integral to maintaining the performance and reliability of truck engines and transmissions 3.

Basic Concepts of Sealing Washers

Sealing washers are components used in mechanical systems to create a tight seal between two surfaces. They function by filling the gap between mating parts, preventing the escape of fluids or gases. In mechanical systems, sealing washers play a role in maintaining system integrity by ensuring that fluids remain contained within their designated pathways. This containment is vital for the efficient operation of engines and other mechanical components 1.

Purpose of the 4899824 Sealing Washer

The Cummins 4899824 Sealing Washer is specifically designed to play a role in the operation of commercial trucks by providing a reliable seal in various systems. It is commonly used in engine and transmission applications, where it helps to prevent leaks and maintain system pressure. By ensuring that fluids remain within their intended pathways, this sealing washer contributes to the overall efficiency and reliability of the truck’s mechanical systems 3.

Key Features

The Cummins 4899824 Sealing Washer features a design that enhances its performance in demanding environments. It is composed of durable materials that resist wear and corrosion, ensuring long-lasting service. The washer’s precise dimensions and smooth surface contribute to its ability to create a secure seal, while its flexibility allows it to adapt to slight misalignments between mating parts 3.

Benefits

Using the Cummins 4899824 Sealing Washer provides several benefits. It contributes to improved system efficiency by ensuring that fluids remain contained, which can lead to enhanced performance and reduced maintenance costs. The washer’s durable construction promotes longevity, while its reliable sealing capability enhances the overall reliability of the truck’s mechanical systems 3.

Installation Process

Proper installation of the Cummins 4899824 Sealing Washer is crucial for ensuring its effectiveness. The installation process involves cleaning the mating surfaces to remove any debris or contaminants. The washer should be placed between the mating parts, ensuring that it is properly aligned and seated. Tools such as torque wrenches may be required to achieve the correct tightening specifications, ensuring that the seal is secure without over-tightening, which could damage the washer or the mating surfaces 2.

Troubleshooting Common Issues

Common problems associated with sealing washers include leaks and washer failure. To address these issues, it is important to inspect the washer for signs of wear or damage. If a leak is detected, the washer may need to be replaced. Ensuring that the mating surfaces are clean and properly aligned can also help prevent issues. Regular maintenance and inspection can aid in identifying potential problems before they lead to significant issues 3.

Maintenance Tips

To ensure optimal performance and longevity of the Cummins 4899824 Sealing Washer, regular maintenance is recommended. This includes inspecting the washer for signs of wear or damage during routine maintenance checks. If the washer shows signs of deterioration, it should be replaced to maintain system integrity. Keeping the mating surfaces clean and free of contaminants will also contribute to the washer’s effectiveness 3.

Role in Engine and Transmission Systems

The Cummins 4899824 Sealing Washer plays a role in the functionality of engine and transmission systems by providing a reliable seal that prevents leaks and maintains system pressure. In engine applications, it helps to ensure that coolant and oil remain contained, contributing to efficient engine operation. In transmission systems, the washer aids in maintaining hydraulic pressure, which is vital for smooth gear shifting and overall transmission performance 3.

Impact on Fuel Efficiency

Proper sealing, achieved through the use of the Cummins 4899824 Sealing Washer, can influence fuel efficiency in commercial trucks. By preventing leaks and maintaining system pressure, the washer contributes to the efficient operation of engine and transmission systems. This efficiency can lead to improved fuel economy, as the truck’s mechanical systems operate more effectively with minimal energy loss due to leaks 3.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and aftermarket parts. With a history of innovation and a commitment to quality, Cummins serves customers in over 190 countries and territories, providing reliable and efficient power solutions for various industries, including commercial trucking. The company’s extensive product range and dedication to customer satisfaction have established Cummins as a trusted name in the automotive industry 3.

Sealing Washer Part 4899824 in Cummins Engines

The Sealing Washer part 4899824, manufactured by Cummins, is a critical component in several of their engine models. This part is designed to ensure a secure and leak-free seal in various engine applications.

ISBE CM800 and ISL9 CM2150 SN

In the ISBE CM800 and ISL9 CM2150 SN engines, the sealing washer part 4899824 plays a pivotal role in maintaining the integrity of the engine’s sealing systems. These engines, known for their robust performance and reliability, depend on this washer to prevent fluid leaks and maintain optimal pressure within the engine’s critical components 3.

QSB4.5 CM850 (CM2850)

Similarly, in the QSB4.5 CM850 (CM2850) engine, the sealing washer part 4899824 is integral to the engine’s sealing mechanisms. This engine, which is part of Cummins’ lineup of high-performance diesel engines, relies on this washer to ensure that all seals are properly maintained, thereby enhancing the engine’s longevity and efficiency 3.

The consistent use of the sealing washer part 4899824 across these engines underscores its importance in maintaining the overall performance and reliability of Cummins engines.

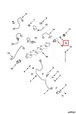

Role of Part 4899824 Sealing Washer in Engine Systems

The part 4899824 Sealing Washer is an essential component in various engine systems, ensuring the integrity and efficiency of fluid transfer and pressure maintenance.

In the Cooler system, the Sealing Washer is employed to prevent leaks at connection points, maintaining the coolant’s flow and temperature regulation efficiency.

Within the Torque Converter Oil system, it ensures that the oil remains contained, facilitating smooth power transmission from the engine to the transmission.

In the Fuel Manifold and Injector Plumbing, the Sealing Washer plays a significant role in maintaining fuel pressure and preventing leaks. This is vital for consistent fuel delivery to the engine cylinders, ensuring optimal combustion and performance.

The Plumbing systems, whether for fuel or other fluids, rely on the Sealing Washer to create a secure seal at joints and connections. This prevents fluid loss and maintains system pressure, which is essential for the efficient operation of the engine.

In the Pressure Valve Assembly, the Sealing Washer is used to maintain the integrity of the valve’s sealing surfaces. This ensures that the valve can effectively regulate pressure within the system, contributing to the overall stability and performance of the engine.

Lastly, in the Upper Engine Gasket Set, the Sealing Washer complements the gaskets by providing additional sealing at specific points, enhancing the overall sealing effectiveness of the engine’s upper components.

Through its application in these systems, the part 4899824 Sealing Washer significantly contributes to the engine’s reliability, efficiency, and longevity 3.

Conclusion

The Cummins 4899824 Sealing Washer is a vital component in the maintenance and operation of commercial truck engines and transmissions. Its role in preventing leaks, maintaining system pressure, and contributing to fuel efficiency underscores its importance in ensuring the reliability and performance of truck mechanical systems. Regular maintenance and proper installation are key to maximizing the benefits of this sealing washer 3.

-

Stiesch, Gunnar. Modeling Engine Spray and Combustion Processes. Springer Verlag, 2003.

↩ -

Martyr, A.J. Engine Testing: Theory and Practice: Third Edition. SAE International, 2007.

↩ -

Kasab, John, and Andrea Strzelec. Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International, 2020.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.