This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

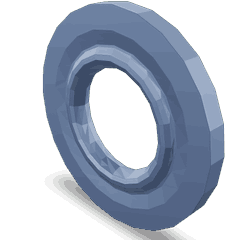

The 4900320 Sealing Washer, a component manufactured by Cummins, is designed to ensure the integrity of various fluid systems within commercial trucks. Cummins, a reputable name in the automotive and heavy-duty truck industry, produces this washer to meet the demanding requirements of truck operations, reflecting its commitment to quality and innovation 1.

Basic Concepts of Sealing Washers

Sealing washers are essential components in mechanical systems, used to prevent leaks and maintain the integrity of fluid systems. They function by creating a seal between two surfaces, typically where a fluid or gas passes through. In trucks, sealing washers are crucial for the efficient operation of systems such as fuel, hydraulic, and cooling systems, contributing to the vehicle’s overall reliability and performance by maintaining system pressures and preventing contamination 2.

Purpose of the 4900320 Sealing Washer

The 4900320 Sealing Washer is designed to serve in various truck systems where fluid sealing is required. Its primary role is to ensure that connections within these systems remain leak-free, thereby maintaining system efficiency and reliability. This washer is applied in systems where precise sealing is necessary to prevent fluid loss and ensure optimal operation of the truck 3.

Key Features

This Cummins part is characterized by its material composition and design attributes that enhance its performance. Made from high-quality materials, it is designed to withstand the pressures and temperatures encountered in truck systems. Its unique characteristics include a precise fit and durable construction, ensuring it can perform under demanding conditions.

Benefits

Utilizing the 4900320 Sealing Washer in truck systems offers several benefits. It contributes to improved system efficiency by ensuring tight seals, which prevents fluid loss and maintains system pressures. Additionally, its durable construction promotes longevity, reducing the need for frequent replacements. The reliability it offers is crucial for maintaining consistent truck performance.

Installation Process

Proper installation of the 4900320 Sealing Washer is key to ensuring its optimal performance. The process involves cleaning the surfaces where the washer will be placed, ensuring no debris or old sealant remains. The washer should be positioned correctly to achieve the desired seal. Tools or equipment required may include a torque wrench for tightening connections to the manufacturer’s specifications. Following best practices during installation helps ensure the washer functions as intended.

Troubleshooting Common Issues

Common issues with sealing washers include leaks, which can arise from improper installation, wear, or damage. Addressing these problems involves inspecting the washer for signs of wear or damage and replacing it if necessary. Ensuring correct installation practices are followed can prevent many issues associated with sealing washers.

Maintenance Tips

Regular maintenance of the 4900320 Sealing Washer is important for ensuring continued efficient operation. This includes periodic inspections for signs of wear or damage and replacing the washer as needed. Care instructions may involve cleaning the washer and its surrounding areas to prevent contamination and ensure optimal performance.

Role in Truck Systems

The 4900320 Sealing Washer integrates with other components within truck systems, playing a role in maintaining the integrity of fluid systems. Its contribution to overall system performance is significant, as it ensures that systems operate under the correct pressures and without leaks, which is vital for the efficient and reliable operation of the truck.

Cummins: Manufacturer Overview

Cummins is a reputable manufacturer in the automotive and heavy-duty truck industry, known for its history of innovation and commitment to quality. The company’s reputation is built on producing reliable and high-performance components, including the 4900320 Sealing Washer. Cummins’ dedication to quality and innovation ensures that its products meet the rigorous demands of truck operations.

Role of 4900320 Sealing Washer in Engine Systems

The 4900320 Sealing Washer is integral to maintaining the integrity and efficiency of various engine components. It is strategically positioned to ensure optimal performance and longevity of the engine system.

Integration with the Block and Cylinder

In the engine block, the sealing washer works in conjunction with the cylinder to prevent any fluid leakage. This is particularly important in the area where the cylinder interfaces with the block, as any seepage can lead to a loss of compression and reduced engine efficiency. The washer ensures a tight seal, maintaining the pressure necessary for efficient combustion.

Function within the Cover and Front Gear

The cover, especially the front gear cover, relies on the sealing washer to maintain a secure environment. The front gear cover houses critical components such as the front gear, and any intrusion of contaminants or loss of lubricants can severely impact performance. The sealing washer here plays a key role in keeping the internals clean and well-lubricated, thus ensuring smooth operation of the front gear.

Contribution to the Gasket Set

When integrated into a gasket set, the sealing washer enhances the overall sealing capability of the set. Gaskets are often used between mating surfaces to prevent leaks, and the addition of a sealing washer can significantly improve the seal’s effectiveness. This is particularly beneficial in high-stress areas where vibrations and thermal expansion can compromise the seal over time.

Conclusion

In summary, the 4900320 Sealing Washer is a vital component in various engine systems, ensuring that critical interfaces remain sealed and operational. Its application across different components underscores its versatility and importance in maintaining engine performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.