This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

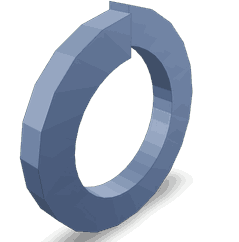

The 4900883 Lock Washer, a component manufactured by Cummins, is designed for use in commercial trucks. This part plays a role in maintaining the integrity of bolted connections, particularly in environments where vibrations and dynamic loads are common 1.

Basic Concepts of Lock Washers

Lock washers are specialized washers used in fastening applications to prevent the loosening of bolts and nuts. They function by creating additional friction or by deforming to grip the surfaces they are placed between, which helps to maintain the tension in a bolted joint 2.

Purpose of the 4900883 Lock Washer

The 4900883 Lock Washer is designed to enhance the security of bolted connections in commercial trucks. It operates by preventing the loosening of fasteners under dynamic conditions, such as those encountered on rough roads or during heavy-duty operations 3.

Key Features

This Cummins part features a split design that allows it to flex and grip the mating surfaces when a bolt is tightened. It is made from high-strength steel, which provides durability and resistance to wear. The material composition ensures that the lock washer can withstand the harsh conditions typical of commercial truck operations, including exposure to moisture, dirt, and extreme temperatures 4.

Benefits

Using the 4900883 Lock Washer offers several advantages. It provides improved fastening security by preventing the loosening of bolts and nuts, which is vital in maintaining the structural integrity of commercial trucks. Its resistance to vibration ensures that fasteners remain tight, even under dynamic loads. Additionally, the lock washer’s durable construction contributes to its longevity, making it a reliable component in harsh operating environments 5.

Installation Guidelines

To install the 4900883 Lock Washer, place it under the head of the bolt or nut before tightening. Ensure that the split in the washer is aligned with the direction of the applied force to maximize its locking effect. Tighten the bolt or nut to the manufacturer’s specified torque settings to ensure optimal performance and durability of the lock washer 6.

Troubleshooting and Maintenance

Common issues with lock washers include deformation or failure due to excessive torque or corrosion. To troubleshoot problems, inspect the lock washer for signs of wear or damage before reusing it. Regular maintenance involves checking bolted connections for tightness and replacing lock washers as needed to prevent failure. Keeping the washer and mating surfaces clean and free of corrosion will also help extend its lifespan 7.

Compatibility with Cummins Engines

The Lock Washer 4900883 is compatible with various Cummins engines, including the A1400, A1700, A2000, and A2300. These engines benefit from the added security provided by this lock washer, which helps maintain the integrity of bolted connections and prevent loosening due to vibration or other operational stresses 8.

Role of the 4900883 Lock Washer in Engine Systems

In engine systems, the 4900883 Lock Washer ensures the secure attachment of various components. When integrated with the alternator, it maintains the integrity of the mounting system by preventing fasteners from loosening due to engine vibrations. This ensures that the alternator remains firmly attached, allowing it to operate efficiently without the risk of detachment or misalignment 9.

Conclusion

The 4900883 Lock Washer is a small yet significant component that enhances the durability and performance of engine systems by securing critical connections and preventing fastener loosening. Its compatibility with various Cummins engines and its role in maintaining the integrity of bolted joints make it an essential part for commercial truck operations.

-

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Majewski, Addy, and Hannu Jaskelainen. Diesel Emissions and Their Control: Second Edition. SAE International, 2023.

↩ -

Naunheimer, Harald, et al. Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg, 2011.

↩ -

Cummins Inc. Owners Manual for ISX15 CM2250 SN. Bulletin Number 4310734.

↩ -

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Cummins Inc. Owners Manual for ISX15 CM2250 SN. Bulletin Number 4310734.

↩ -

Majewski, Addy, and Hannu Jaskelainen. Diesel Emissions and Their Control: Second Edition. SAE International, 2023.

↩ -

Cummins Inc. Owners Manual for ISX15 CM2250 SN. Bulletin Number 4310734.

↩ -

Naunheimer, Harald, et al. Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.