This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4927981 Copper Washer, manufactured by Cummins, is a critical component in the maintenance and operation of commercial trucks. Cummins, a renowned name in the commercial truck industry, produces a range of parts designed to enhance the efficiency and reliability of truck systems. This part plays a significant role in ensuring the smooth operation of various truck components.

Basic Concepts of Copper Washers

A copper washer is a type of gasket made from copper, used in mechanical systems to create seals and prevent leaks. Copper washers are commonly employed in applications where a reliable seal is required, due to their ability to conform to the surfaces they are placed between. This conformity ensures that gaps are effectively sealed, preventing the escape of fluids or gases and maintaining system integrity 1.

Purpose of Copper Washer 4927981 in Truck Operation

The 4927981 Copper Washer is specifically designed for use in commercial trucks, where it serves to seal connections in various systems and components. Its application ranges from fuel systems to hydraulic systems, where it helps maintain pressure and prevent leaks. By ensuring a tight seal, the washer contributes to the efficient operation of the truck, reducing the risk of system failures due to leaks 2.

Key Features

The 4927981 Copper Washer is characterized by its copper material composition, which offers excellent conductivity and corrosion resistance. Its design is tailored to fit specific applications within truck systems, ensuring a secure and effective seal. The washer’s unique characteristics, such as its ability to withstand high temperatures and pressures, enhance its performance and durability in demanding environments.

Benefits of Using Copper Washers

Utilizing copper washers in truck maintenance offers several advantages. Copper’s natural properties, including high thermal conductivity and resistance to corrosion, make it an ideal material for washers. These properties ensure that the washers can withstand the harsh conditions often encountered in truck operations, providing reliable sealing performance and contributing to the overall efficiency and safety of the vehicle.

Installation and Usage Guidelines

To install the 4927981 Copper Washer, it is important to follow a series of steps to ensure a secure fit. Begin by cleaning the surfaces where the washer will be placed to remove any debris or old washer material. Place the washer onto the fitting or connection point, ensuring it is correctly aligned. Use the appropriate tools to tighten the connection, taking care not to over-tighten, which could damage the washer or the connection itself. Proper installation is key to achieving an effective seal and preventing leaks.

Troubleshooting Common Issues

Common issues with copper washers may include leaks or failure to seal properly. These problems can often be traced back to incorrect installation, damage to the washer, or degradation over time. To address these issues, first, ensure that the washer is correctly installed and that the surfaces it seals against are clean and undamaged. If the washer appears worn or damaged, replacement may be necessary to restore the seal’s integrity.

Maintenance Tips

To ensure the longevity and optimal performance of copper washers, regular maintenance is recommended. This includes inspecting washers for signs of wear or damage during routine maintenance checks and cleaning them as necessary to remove any buildup that could affect their sealing ability. Replacement schedules should be adhered to, based on the manufacturer’s recommendations or as dictated by the condition of the washers.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s commitment to advancing technology and meeting the needs of its customers underscores its position as a leader in the field.

Compatibility of Copper Washer Part 4927981 with Cummins Engines

The 4927981 Copper Washer, manufactured by Cummins, is a critical component that fits into various Cummins engine models. This part is designed to ensure proper sealing and functionality in the engine’s operation. Here is a detailed look at its compatibility across different engine series:

QSK19 Series

- QSK19 CM2350 K105

- QSK19 CM2350 K114

- QSK19 CM850 MCRS

The QSK19 series engines, including the CM2350 and CM850 variants, utilize the 4927981 Copper Washer to maintain optimal performance. This part is essential in these engines for its ability to withstand high temperatures and pressures, ensuring a reliable seal.

QSK38 Series

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

The QSK38 series engines, both the CM2150 and CM850 models, also incorporate the 4927981 Copper Washer. This part is crucial in these engines for its durability and resistance to wear, which is vital for maintaining the integrity of the engine’s sealing systems.

QSK50 Series

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

The QSK50 series engines, including the CM2150 and CM2350 variants, benefit from the use of the 4927981 Copper Washer. This part is integral to these engines, providing the necessary sealing and support to handle the demanding conditions these engines operate under.

QSK60 Series

- QSK60 CM850 MCRS

The QSK60 series engine, specifically the CM850 model, also relies on the 4927981 Copper Washer. This part ensures that the engine maintains its performance and reliability by providing a robust seal that can endure the rigors of continuous operation.

Each of these engines, regardless of their specific model or variant, depends on the 4927981 Copper Washer to function correctly. This part’s design and material properties make it an essential component in ensuring the longevity and efficiency of Cummins engines.

Role of Part 4927981 Copper Washer in Engine Systems

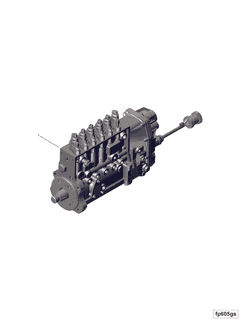

The 4927981 Copper Washer is an essential component in various engine systems, particularly in the fuel delivery subsystem. It is commonly utilized in the assembly of fuel injection pumps and fuel pumps, where it serves to ensure a secure and leak-proof connection between different components.

In the fuel injection pump, the 4927981 Copper Washer is positioned between the pump body and the fuel delivery components. Its primary function is to create a tight seal, preventing fuel leakage and ensuring that the fuel is delivered under the correct pressure to the engine’s combustion chambers. This washer is also used in the connections between the fuel pump and the fuel lines, where it maintains the integrity of the fuel system by sealing the joints and preventing any fuel escape.

Additionally, the 4927981 Copper Washer is employed in the assembly of various pump components, where it ensures that the internal pressures are maintained and that the fuel flow is consistent. Its use in these applications is vital for the efficient operation of the engine, as it helps in maintaining the precise fuel delivery required for optimal engine performance.

Conclusion

The 4927981 Copper Washer is a vital component in the operation and maintenance of commercial trucks, particularly those equipped with Cummins engines. Its role in ensuring reliable seals and preventing leaks contributes significantly to the efficiency and safety of truck systems. Proper installation, regular maintenance, and understanding its compatibility with various engine models are key to maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.