This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

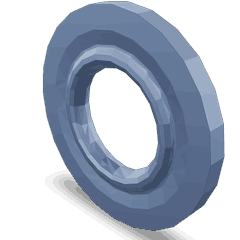

The Cummins 4999779 Sealing Washer is a component designed to ensure the integrity of fluid systems within commercial trucks. It contributes to maintaining the efficiency and reliability of various truck systems by preventing leaks and ensuring proper fluid flow.

Basic Concepts of Sealing Washers

Sealing washers are components used in mechanical systems to create a seal between two surfaces, preventing the leakage of fluids or gases. They function by filling the gap between mating surfaces, ensuring that the system remains closed and operates efficiently. In mechanical systems, sealing washers are vital for maintaining system pressure, preventing contamination, and ensuring the longevity of components 1.

Purpose of the 4999779 Sealing Washer

The 4999779 Sealing Washer is specifically designed to contribute to the fluid systems of commercial trucks. It is applied in various truck systems, including fuel, hydraulic, and cooling systems, where it helps maintain system integrity by sealing connections and preventing leaks. This ensures that the systems operate efficiently and reliably.

Key Features

The 4999779 Sealing Washer features a design that enhances its performance in demanding environments. It is composed of materials that offer durability and resistance to wear and corrosion. Its design ensures a tight seal, even under high pressure, contributing to the overall efficiency and reliability of the truck’s systems.

Benefits

The use of the 4999779 Sealing Washer offers several benefits, including improved system efficiency through effective sealing, enhanced longevity of system components due to reduced wear and leakage, and increased reliability in truck operations by ensuring consistent system performance.

Installation Process

Installing the 4999779 Sealing Washer involves several steps to ensure proper fitting and function. The process includes cleaning the mating surfaces, selecting the correct washer size, and using appropriate tools to install the washer without damage. Following the manufacturer’s guidelines ensures the washer is installed correctly, contributing to the system’s efficiency and reliability.

Troubleshooting Common Issues

Common issues with sealing washers include leaks due to wear, improper installation, or incorrect sizing. Addressing these issues involves inspecting the washer for damage, ensuring correct installation procedures are followed, and selecting the appropriate washer size for the application. Regular inspection and maintenance can help prevent these issues 2.

Maintenance Tips

Regular maintenance of the 4999779 Sealing Washer is key to ensuring optimal performance and longevity. This includes periodic inspection for signs of wear or damage, cleaning the mating surfaces before reinstallation, and replacing the washer as needed. Adhering to these maintenance practices helps maintain the efficiency and reliability of the truck’s systems.

Role in Engine Systems

The 4999779 Sealing Washer integrates into engine systems by sealing connections in fluid pathways, contributing to efficient operation by preventing leaks. This role is vital in maintaining system pressure and ensuring that fluids are delivered where needed without loss, which is crucial for the engine’s performance and longevity 3.

Compatibility with Engine Models

The Cummins Sealing Washer part number 4999779 is designed to fit seamlessly with a variety of engine models. This part is integral to ensuring the integrity of the engine’s sealing system, preventing leaks and maintaining optimal performance.

ISZ13 CM2150 Z105 and QSZ13 CM2150 Z101

The ISZ13 CM2150 Z105 and QSZ13 CM2150 Z101 engines share a common design that benefits from the precise fit of the 4999779 sealing washer. This part is engineered to match the specific sealing requirements of these engines, ensuring a secure and reliable connection.

QSZ13 CM2150 Z102

Similar to its counterparts, the QSZ13 CM2150 Z102 engine also utilizes the 4999779 sealing washer. This part is critical in maintaining the engine’s sealing integrity, preventing any potential leaks that could compromise performance.

Z13 Z108G

The Z13 Z108G engine is another model that is compatible with the 4999779 sealing washer. This part is designed to fit the unique sealing needs of this engine, ensuring that it operates efficiently and reliably.

Each of these engines relies on the 4999779 sealing washer to maintain its sealing system’s integrity, ensuring that the engine performs at its best.

Integration with Engine Components

- Camshaft: The Sealing Washer is often used at the interface between the camshaft and the cylinder head. This ensures that lubrication oil remains within the camshaft bearing surfaces, reducing friction and wear.

- Connecting Rod and Piston: In the lower end of the engine, the Sealing Washer may be employed between the connecting rod and the crankshaft journal. This application helps to maintain oil pressure within the rod bearings, which is essential for the smooth operation of the piston.

- Cylinder Head: When assembling the cylinder head, the Sealing Washer is utilized to create a secure seal between the head and the engine block. This is vital for maintaining compression within the combustion chamber and preventing coolant or oil leaks.

- Cylinder Head Kit: Within a cylinder head kit, the Sealing Washer complements other gaskets and seals. It ensures that all passages for coolant, oil, and combustion gases are properly sealed, contributing to the overall integrity of the head assembly.

- Flywheel Housing: The Sealing Washer is also critical in the flywheel housing, where it helps to seal the interface between the housing and the engine block. This prevents oil leaks and ensures that the flywheel operates within a clean, lubricated environment.

- Injector: In fuel injection systems, the Sealing Washer is used to seal the connection between the injector and the fuel rail or the cylinder head. This is important for maintaining fuel pressure and preventing leaks that could affect engine performance.

- Lower Engine Gasket Kit: As part of a lower engine gasket kit, the Sealing Washer works alongside other gaskets to ensure that all lower end components are properly sealed. This includes the oil pan, timing cover, and other critical areas.

- Performance Parts: For performance-enhanced engines, the Sealing Washer is often used in conjunction with aftermarket components to ensure that all high-stress areas are adequately sealed. This is particularly important in applications where increased power output can lead to higher pressures and temperatures.

Conclusion

The Cummins 4999779 Sealing Washer plays a significant role in the assembly and maintenance of various engine components, ensuring that all critical interfaces are sealed to maintain engine performance and longevity. Its integration into engine systems contributes to efficient operation by preventing leaks and maintaining system pressure.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.