This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

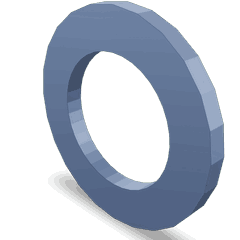

The Cummins 5282802 Plain Washer is a component designed for use in commercial truck operations. It serves a specific function within the mechanical systems of trucks, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and role is fundamental for maintaining and optimizing truck performance.

Basic Concepts of Plain Washers

Plain washers are simple yet vital components in mechanical systems. They are typically flat, annular devices made from metal or other materials. Their general function is to distribute the load of a threaded fastener, such as a bolt or screw, over a larger area, thereby reducing the pressure on the surface and preventing damage. Additionally, plain washers can provide a degree of cushioning and help in reducing vibration and wear between moving parts 1.

Purpose of the Cummins 5282802 Plain Washer

The Cummins 5282802 Plain Washer plays a role in the operation of a truck by ensuring the proper distribution of load from fasteners across various components. It is applied in different truck parts where secure fastening is required, helping to maintain the integrity of the assembly and ensuring that parts remain firmly in place under operational stress 2.

Key Features

The Cummins 5282802 Plain Washer is characterized by several key features that enhance its functionality. These include its material composition, which is selected for durability and resistance to wear, and its design specifications, which ensure it fits precisely within the truck’s mechanical systems. Unique attributes may include specific thickness and outer diameter, tailored to meet the demands of its application 3.

Benefits of Using Plain Washers

Incorporating plain washers like the Cummins 5282802 into truck maintenance and operations offers several advantages. These include improved load distribution, which helps in evenly spreading the force exerted by fasteners, reducing the risk of surface damage. Plain washers also contribute to vibration reduction, enhancing the stability of truck components. Furthermore, their design can offer corrosion resistance, prolonging the lifespan of both the washer and the components it supports 4.

Installation and Usage Guidelines

Proper installation of the Cummins 5282802 Plain Washer involves ensuring it is correctly positioned under the head of a bolt or screw, or within a nut assembly, depending on the specific application. Best practices for usage include checking for the correct size and material compatibility with other truck components to ensure optimal performance and longevity. It is also important to follow manufacturer guidelines for torque settings when tightening fasteners to avoid over-tightening, which can lead to component damage 5.

Troubleshooting and Maintenance

Common issues associated with plain washers include wear and tear, corrosion, and improper installation. Troubleshooting tips involve regularly inspecting washers for signs of damage or deformation and replacing them as necessary. Maintenance practices to ensure longevity and optimal performance include keeping washers and their surrounding areas clean and free from debris, and ensuring that fasteners are tightened to the manufacturer’s specified torque settings 6.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related components. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. Its product range is designed to meet the demanding requirements of commercial vehicle operations, ensuring efficiency, durability, and performance 7.

Role of Part 5282802 Plain Washer in Engine Systems

In the intricate assembly of engine systems, the Cummins 5282802 Plain Washer serves as a fundamental component, ensuring the smooth operation and longevity of various engine parts.

Integration with Camshaft and Gear

The camshaft and gear mechanism is pivotal for the timing of valve operation in an engine. The Plain Washer, when placed between the camshaft and its supporting structures, reduces friction and wear. This results in consistent camshaft rotation, which is essential for precise valve timing and overall engine performance 8.

Function in Cylinder Head Assembly

Within the cylinder head, where combustion takes place, the Plain Washer is often used in the mounting of various components. It provides a smooth surface that minimizes metal-to-metal contact, thereby reducing the risk of galling and seizing. This is particularly important in high-performance engines where components are subjected to extreme conditions 9.

Role in Injector Kit Installation

Injector kits are crucial for fuel delivery in modern engines. The Plain Washer is utilized in the mounting of injectors to the cylinder head. It ensures a secure yet smooth fit, which is vital for the injector’s operation. Proper installation with the Plain Washer helps in maintaining the injector’s alignment and sealing, which is essential for fuel efficiency and engine performance 10.

General Use in Engine Parts

Across various engine parts, the Plain Washer is a common sight. Whether it’s in the assembly of sensors, actuators, or other ancillary components, its role remains consistent: to provide a friction-reducing interface. This not only enhances the operational efficiency of these parts but also contributes to their durability 11.

Contribution to Performance Enhancements

In performance-oriented engine builds, every component counts. The Plain Washer, though small, plays a significant role in maintaining the integrity and efficiency of high-stress areas. Its use in custom engine builds is a testament to its importance in achieving desired performance metrics 12.

Conclusion

In summary, the Cummins 5282802 Plain Washer, though often overlooked, is a key player in the reliable and efficient operation of engine systems. Its application across various components underscores its versatility and importance in both standard and performance engine configurations.

-

Schneider, Wolf-Henning. Pistons and Engine Testing. Springer Nature, 2016.

↩ -

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩ -

Calder, Nigel. Diesel Engine Care and Repair. The McGraw-Hill Companies, 2007.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4021382.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4021382.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4021382.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4021382.

↩ -

Schneider, Wolf-Henning. Pistons and Engine Testing. Springer Nature, 2016.

↩ -

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩ -

Calder, Nigel. Diesel Engine Care and Repair. The McGraw-Hill Companies, 2007.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4021382.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4021382.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.