3009329

Plain Washer

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3009329 Plain Washer is a component designed for use in commercial truck applications. Its purpose is to enhance the functionality and durability of truck assemblies by providing load distribution, surface protection, and connection stability. This washer is integral to the efficient operation of heavy-duty trucks, ensuring that mechanical systems perform reliably under demanding conditions 3.

Basic Concepts of Plain Washers

Plain washers are simple yet vital components in mechanical systems. They function primarily to distribute loads across surfaces, prevent damage to mating parts, and enhance the stability of connections. Typically made from materials such as steel, stainless steel, or brass, plain washers are chosen for their specific properties, including strength, corrosion resistance, and durability. The material selection depends on the application requirements and the environmental conditions the washer will encounter 4.

Purpose and Function of the Cummins 3009329 Plain Washer

This Cummins part plays a specific role in truck operations by ensuring the even distribution of loads across connected parts. This helps in preventing surface damage and wear, which can lead to component failure over time. Additionally, it enhances the stability of connections by providing a uniform surface for bolts and nuts, thereby improving the overall integrity of the assembly. Its design is tailored to meet the rigorous demands of heavy-duty truck applications, ensuring reliable performance 1.

Key Features

The Cummins 3009329 Plain Washer is characterized by its robust design and material composition. It is typically made from high-strength steel, which provides excellent durability and resistance to wear. The washer’s thickness and outer diameter are precisely engineered to meet the specific requirements of its application, ensuring optimal performance. These features contribute to its effectiveness in distributing loads and protecting surfaces, making it a reliable component in heavy-duty truck assemblies 2.

Benefits

The use of the Cummins 3009329 Plain Washer offers several benefits. It improves load distribution across connected parts, which helps in reducing stress concentrations and preventing premature wear. Enhanced connection stability ensures that assemblies remain secure under varying loads and conditions. Additionally, the durability of the washer contributes to extended component life, potentially leading to cost savings through reduced maintenance and replacement needs 3.

Troubleshooting and Maintenance

Common issues with plain washers include wear and tear due to repeated loading and unloading, as well as improper installation. Regular inspections are recommended to identify signs of wear or damage early. Maintenance practices should include checking for proper installation, ensuring that washers are correctly positioned and not overloaded. Replacement schedules should be established based on the operational conditions and observed wear patterns to maintain the effectiveness and longevity of the washers 4.

Cummins Engine Part 3009329: Plain Washer Application

The Cummins part number 3009329, a Plain Washer, is a crucial component in the assembly and maintenance of various Cummins engines. This part is designed to provide a smooth and even surface for mounting and securing components, ensuring the integrity and functionality of the engine systems.

Application in Cummins Engines

- 15N CM2380 M104B: The Plain Washer 3009329 is utilized in the 15N CM2380 M104B engine to maintain alignment and stability of various parts, ensuring optimal performance and longevity.

- 6B5.9, 6C8.3, 8.3 G, G5.9, G5.9 CM558, G8.3, G8.3 CM558, GTA8.3 CM558: In these engines, the Plain Washer 3009329 is essential for securing and aligning components, contributing to the overall efficiency and reliability of these engines.

- A1400, A1700, A2000, A2300: For these engines, the Plain Washer 3009329 plays a vital role in maintaining the structural integrity of the engine by ensuring proper alignment and fastening of parts.

- B3.3, B5.9 GAS PLUS CM556, C GAS PLUS CM556: In these engines, the Plain Washer 3009329 is used to secure and stabilize various components, ensuring that the engine operates smoothly and efficiently.

- ISC CM2150, ISC CM554, ISC CM850, ISC8.3 CM2250: The Plain Washer 3009329 is also integral to these engines, where it helps in maintaining the alignment and stability of critical engine parts.

- ISL CM2150, ISL CM554, ISL G CM2180, ISL9 CM2150 SN, ISL9 CM2250: In these engines, the Plain Washer 3009329 ensures that components are properly aligned and secured, contributing to the overall performance and durability of these engines.

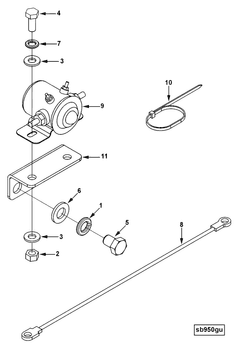

Role of Part 3009329 Plain Washer in Engine Systems

This part is an essential component in various engine systems, providing necessary support and functionality. In the Air Compressor Kit, it ensures secure attachment and alignment of components, maintaining efficient airflow and pressure regulation. Within the Air Intake Connection, the washer facilitates a tight seal, preventing air leaks that could compromise engine performance.

In the Cam Housing Module, the washer plays a role in maintaining the integrity of the cam housing, ensuring smooth operation of the camshaft and related components. The Compressor Brace Kit utilizes the washer to secure the brace, enhancing the structural stability of the compressor assembly.

For the Crank Seal, the washer aids in creating a reliable seal, preventing oil leaks and ensuring the crank operates within specified tolerances. In the Cylinder Block Cover, it helps in securing the cover, protecting internal components from contaminants and ensuring proper engine function.

The EBM-Location (Electronic Brake Module Location) benefits from the washer by providing a stable mounting point, crucial for the precise operation of the brake system. In the Turbocharger setup, the washer is used to secure various connections, ensuring the turbocharger operates efficiently without undue stress on the mounting points.

The Filter Head Kit employs the washer to maintain a secure and leak-free connection, essential for the proper filtration of air or fluids. In the Flywheel Top Level Assembly Housing and Flywheel TLA, the washer ensures that all components are correctly aligned and secured, contributing to the smooth operation of the flywheel.

The Junction Box Panel uses the washer to secure electrical connections, ensuring reliable and safe operation of the engine’s electrical systems. In the VE Conversion kit, the washer helps in maintaining the structural integrity of the conversion components, ensuring they function as intended.

For the Oil Bypass Filter and Oil Filler Assembly, the washer ensures that all connections are secure, preventing oil leaks and maintaining the efficiency of the oil system. The Oil Jumper Mounting Cover and Oil Transfer Connection also rely on the washer to create secure and reliable connections, essential for the proper transfer and management of oil within the engine.

In the Refrigerant Compressor Drive Kit and Refrigerant Compressor Mounting, the washer ensures that all components are securely attached, facilitating efficient operation of the refrigerant system. The Rocker Lever assembly uses the washer to maintain proper alignment and secure attachment, ensuring smooth and reliable operation of the valvetrain.

The Speed Sensor mounting benefits from the washer by providing a stable and secure attachment point, crucial for accurate speed readings. In the Thermostat Housing, the washer helps in creating a seal that prevents coolant leaks, ensuring the engine operates within the optimal temperature range.

The Transmission and Transmission Control Mounting utilize the washer to secure various components, ensuring the transmission operates smoothly and reliably. The Turbocharger Mounting Kit and Wiring Brace also rely on the washer to create secure and stable connections, essential for the efficient and safe operation of the engine systems.

Conclusion

The Cummins 3009329 Plain Washer is a critical component in the maintenance and operation of heavy-duty truck engines. Its role in load distribution, surface protection, and connection stability ensures the reliability and durability of engine systems. Regular maintenance and proper installation are essential to maximize the benefits of this part, contributing to the overall performance and longevity of the engines it supports.

-

ElGindy, Moustafa and ElSayegh, Zeinab. Road and Off-Road Vehicle Dynamics. Springer Nature, 2023.

↩ -

Rajamani, Rajesh. Vehicle Dynamics and Control. Springer, 2005.

↩ -

Van Gelder, Kirk T. Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning, 2018.

↩ ↩ -

Maclaurin, Bruce. High Speed Off-Road Vehicles. Wiley, 2018.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.