3025100

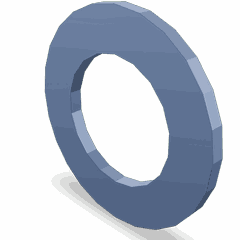

Plain Washer

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3025100 Plain Washer is a component designed for use in heavy-duty truck applications. Its purpose is to provide a stable and efficient interface between various mechanical parts, ensuring optimal performance and longevity of the truck’s components. This washer is integral to the fastening systems used in trucks, contributing to the overall stability and efficiency of the vehicle.

Basic Concepts of Plain Washers

Plain washers are simple yet vital components in mechanical systems. They function primarily to distribute loads, prevent damage to surfaces, and provide a degree of isolation between parts. By doing so, they enhance the stability and efficiency of various assemblies. In the context of heavy-duty trucks, plain washers play a significant role in maintaining the integrity of fastening systems, which are subject to significant stress and vibration 1.

Purpose of the Cummins 3025100 Plain Washer

The Cummins 3025100 Plain Washer is specifically designed to serve in fastening systems within heavy-duty trucks. It contributes to load distribution, ensuring that the force applied by bolts or screws is evenly spread across the connected surfaces. This even distribution helps prevent damage to the surfaces and reduces the risk of fastener loosening, which can be particularly problematic in the demanding conditions faced by heavy-duty trucks.

Key Features

The Cummins 3025100 Plain Washer is characterized by several key features that enhance its performance and durability. These include its material composition, which is typically a high-strength alloy designed to withstand the rigors of heavy-duty applications. The dimensions of the washer are carefully engineered to fit specific applications, ensuring optimal performance. Additionally, any unique design elements, such as specific thickness or outer diameter, are intended to improve its functionality in the intended application.

Benefits of Using Cummins 3025100 Plain Washer

Utilizing the Cummins 3025100 Plain Washer offers several advantages. It provides improved fastening security by ensuring that bolts and screws are properly seated and that loads are evenly distributed. The material composition of the washer offers resistance to wear and corrosion, which is particularly beneficial in the harsh environments often encountered by heavy-duty trucks. Furthermore, the use of this washer contributes to the longevity of truck components by reducing the likelihood of fastener failure and surface damage 2.

Installation and Usage Guidelines

Proper installation of the Cummins 3025100 Plain Washer is crucial for its effective function. It should be placed under the head of a bolt or screw, ensuring that it is correctly aligned with the fastener and the surface it is intended to protect. Best practices for usage include verifying that the washer is the correct size and material for the application and ensuring that it is not over-tightened, which could lead to deformation or failure. Compatibility with other truck components should also be considered to ensure optimal performance.

Troubleshooting and Maintenance

Common issues associated with plain washers include wear, deformation, and corrosion. Regular inspection for these issues can help identify problems early, allowing for timely replacement or repair. Maintenance tips include keeping the washers clean and free from debris, which can contribute to wear, and ensuring that they are properly lubricated if the application requires it. Following these practices can help ensure the optimal performance and longevity of the Cummins 3025100 Plain Washer 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive and heavy-duty truck industry. The company’s commitment to excellence is reflected in its wide range of products, which are designed to meet the demanding requirements of various applications, including heavy-duty trucks. Cummins’ focus on quality, reliability, and performance ensures that its components, like the 3025100 Plain Washer, contribute to the efficiency and durability of the vehicles they are used in.

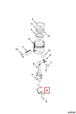

Cummins Engine Part 3025100: Plain Washer Compatibility

The Cummins part 3025100, a Plain Washer, is a critical component used in various Cummins engines. This part is designed to provide a smooth and even distribution of pressure, ensuring the integrity and functionality of the engine’s assemblies. Below is a detailed look at how this washer fits within the specified engines:

G855 and NH/NT 855 Engines

The G855 and NH/NT 855 engines are part of Cummins’ lineup of heavy-duty diesel engines. The Plain Washer 3025100 is used in these engines to maintain the alignment and stability of various components, ensuring that the engine operates smoothly and efficiently. Its placement is crucial in areas where it needs to prevent leaks and secure connections.

K19 and QSK19 Engines

The K19 and QSK19 engines, including the CM500 and CM850 MCRS variants, are high-performance engines designed for demanding applications. The Plain Washer 3025100 is integral to these engines, providing essential support and sealing in critical junctures. Its role is vital in maintaining the structural integrity and operational efficiency of these powerful engines.

N14 G and V28 Engines

The N14 G and V28 engines are known for their robust design and reliability. The Plain Washer 3025100 fits seamlessly into these engines, ensuring that all connected parts are held securely in place. This washer is particularly important in areas where precise alignment and pressure distribution are necessary to prevent wear and ensure longevity.

Grouping of Engines

- Heavy-Duty Engines: G855, NH/NT 855

- High-Performance Engines: K19, QSK19 CM500, QSK19 CM850 MCRS

- Robust Engines: N14 G, V28

Each of these engines benefits from the Plain Washer 3025100 in unique ways, ensuring that the engine components remain aligned and secure, ultimately contributing to the overall performance and reliability of the engine.

Role of Part 3025100 Plain Washer in Engine Systems

The part 3025100 Plain Washer is an essential component in various engine systems, providing necessary spacing, alignment, and vibration dampening between different parts. Here’s how it integrates with the provided components:

Connection Rod and Piston Assembly

In the connection rod and piston assembly, the Plain Washer is used to ensure proper spacing between the connecting rod and the piston pin. This helps in maintaining the correct alignment and reducing friction, which is vital for the smooth operation of the engine.

Camshaft and Engine Mounting

When installed in conjunction with the camshaft and engine mounting parts kit, the Plain Washer assists in securing the camshaft in place while allowing for minor adjustments. It also helps in distributing the load evenly across the mounting points, reducing wear and tear on the engine block.

Cylinder Block and Long Block

Within the cylinder block kit and cylinder long block, the Plain Washer is employed to maintain the precise distance between the cylinder walls and the piston. This ensures optimal compression and efficient combustion, contributing to the overall performance of the engine.

Flywheel and Ring Gear

In the flywheel and ring gear setup, the Plain Washer plays a role in aligning the flywheel with the crankshaft. It also helps in absorbing vibrations, which is essential for smooth engine operation and longevity of the components.

Front Engine Support and Adapter

For the front engine support and front engine support adapter, the Plain Washer ensures that the engine is mounted securely without excessive tightness, which could lead to stress on the engine mounts or the engine itself. It allows for slight movement, accommodating thermal expansion and contraction.

Lubricating Oil Filter and Miscellaneous Mounting

In the lubricating oil filter and miscellaneous mounting applications, the Plain Washer helps in maintaining the correct gap between the filter housing and the engine block. This ensures efficient oil flow and filtration, which is crucial for engine lubrication and cooling.

Performance Parts and Vibration Damper

In performance parts and the vibration damper, the Plain Washer is used to fine-tune the fit and function of high-performance components. It helps in reducing unwanted vibrations and ensuring that performance enhancements do not compromise the engine’s reliability.

Short Block and Short Block Engine Kit

Within the short block and short block engine kit, the Plain Washer is utilized to ensure that all components are correctly aligned and spaced. This is particularly important in high-precision engine assemblies where even minor misalignments can lead to significant performance issues.

By understanding the role of the Plain Washer in these various engine systems, engineers and mechanics can better appreciate its importance in maintaining the integrity and performance of the engine.

Conclusion

The Cummins 3025100 Plain Washer is a critical component in heavy-duty truck and engine applications. Its role in load distribution, surface protection, and fastening security contributes to the overall performance and longevity of the vehicle. Proper installation, maintenance, and understanding of its application in various engine systems are essential for maximizing its benefits.

-

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Hilgers, M., & Achenbach, W. (2021). Vocational Vehicles and Applications. Springer Vieweg.

↩ -

Hilgers, M. (2023). Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.