This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

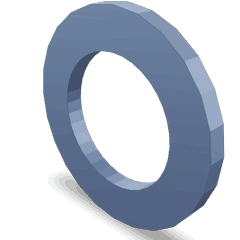

The Cummins 3035177 Plain Washer is a specialized component designed for use in heavy-duty truck applications. Its purpose is to provide a stable and efficient interface between various mechanical components, ensuring optimal performance and longevity of the truck’s systems. This washer is integral to the fastening systems used in trucks, contributing to the overall reliability and durability of the vehicle.

Basic Concepts of Plain Washers

Plain washers are simple yet vital components in mechanical systems. They serve multiple functions, including distributing loads, preventing damage to surfaces, and enhancing the stability of fastenings. By providing a uniform distribution of force, plain washers help to prevent wear and tear on both the fastener and the surface it contacts. This contributes to the efficiency and longevity of the mechanical components they support 1.

Purpose of the Cummins 3035177 Plain Washer

The Cummins 3035177 Plain Washer plays a specific role in the operation of heavy-duty trucks. It is primarily used in fastening systems to ensure that bolts and nuts are securely attached without causing damage to the surfaces they contact. This washer aids in load distribution, which is crucial for maintaining the integrity of the truck’s components under heavy loads and varying conditions 2. Its application is critical in ensuring that fastenings remain secure and efficient throughout the truck’s operational life.

Key Features

The Cummins 3035177 Plain Washer is characterized by several key features that enhance its performance and durability. It is made from high-quality materials that offer resistance to wear and corrosion, ensuring longevity in demanding environments. The dimensions and design of the washer are meticulously engineered to provide optimal load distribution and stability. These features contribute to the washer’s ability to perform reliably in heavy-duty applications.

Benefits of Using Cummins 3035177 Plain Washer

The use of the Cummins 3035177 Plain Washer offers several advantages. It provides improved fastening security, ensuring that components remain firmly attached under various conditions. The washer’s resistance to wear and corrosion enhances its durability, reducing the need for frequent replacements. Additionally, its reliable performance contributes to the overall efficiency and safety of the truck, making it a valuable component in heavy-duty applications 3.

Installation Guidelines

Proper installation of the Cummins 3035177 Plain Washer is crucial for ensuring optimal performance and longevity. To install the washer, first, ensure that the surface is clean and free of debris. Place the washer under the bolt or nut, ensuring it is correctly aligned. Tighten the fastening gradually to avoid over-tightening, which could damage the washer or the surface. Following these steps will help maintain the washer’s integrity and ensure secure fastening.

Troubleshooting Common Issues

Common issues associated with plain washers include wear, deformation, or improper fit. If a washer shows signs of wear or deformation, it should be replaced to maintain the integrity of the fastening system. Ensuring that the washer is the correct size and fit for the application is also important. Regular inspection and maintenance can help identify and address these issues before they lead to more significant problems.

Maintenance Tips

Regular maintenance of the Cummins 3035177 Plain Washer is important for prolonging its service life. Inspect the washer periodically for signs of wear or damage. Clean the washer and the surrounding area to remove any debris or contaminants that could affect its performance. If the washer shows significant wear or damage, replace it to ensure the continued reliability of the fastening system.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the automotive and heavy-duty truck industry. The company’s product range includes a variety of components designed to enhance the performance, efficiency, and reliability of vehicles, making Cummins a trusted name in the industry.

Cummins Engine Part 3035177: Plain Washer Compatibility

The Cummins Plain Washer part number 3035177 is a versatile component designed to fit a wide range of Cummins engines. This washer is essential for ensuring proper sealing and alignment in various engine configurations. Below is a detailed overview of the engines with which this part is compatible:

ISF Series Engines

- ISF2.8 CM2220 F117

- ISF2.8 CM2220 F129

These engines are part of the ISF series, known for their efficiency and reliability in various applications. The Plain Washer 3035177 is used to maintain the integrity of connections and seals within these engines.

ISX Series Engines

- ISX CM570

- ISX CM871

- ISX15 CM2250

- ISX15 CM2350 X101

The ISX series engines are renowned for their power and performance. The Plain Washer 3035177 is integral in these engines, ensuring that components are properly aligned and sealed, contributing to the overall efficiency and longevity of the engine.

L10 Series Engines

- L10 CELECT

- L10 GAS

- L10 MECHANICAL

The L10 series engines are designed for durability and efficiency. The Plain Washer 3035177 is used in these engines to ensure that various parts are correctly aligned and sealed, maintaining the engine’s performance.

M11 Series Engines

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

The M11 series engines are known for their versatility and reliability. The Plain Washer 3035177 is a critical component in these engines, ensuring proper alignment and sealing of various parts.

QSF Series Engines

- QSF2.8 CM2880 F104

- QSF2.8 CM2880 F105

- QSF2.8 CM2880 F108

- QSF2.8 CM2880 F114

The QSF series engines are designed for heavy-duty applications. The Plain Washer 3035177 is used in these engines to maintain the integrity of connections and seals, ensuring optimal performance and durability.

QSK Series Engines

- QSK60 CM500

- QSK60 CM850 MCRS

- QSK78 CM500

The QSK series engines are known for their power and efficiency. The Plain Washer 3035177 is essential in these engines, ensuring that components are properly aligned and sealed, contributing to the engine’s overall performance.

QSV Series Engine

- QSV91-G4 CM558/CM700 V102

The QSV series engine is designed for high-performance applications. The Plain Washer 3035177 is used in this engine to ensure proper alignment and sealing of various parts, maintaining the engine’s efficiency and reliability.

X Series Engines

- X12 CM2350 X119B

- X15 CM2350 X116B

The X series engines are designed for durability and performance. The Plain Washer 3035177 is used in these engines to ensure that components are properly aligned and sealed, contributing to the engine’s overall efficiency and longevity.

K19 Engine

- K19

The K19 engine is known for its reliability and efficiency. The Plain Washer 3035177 is used in this engine to ensure proper alignment and sealing of various parts, maintaining the engine’s performance.

R2.8 Engine

- R2.8 CM2220 R101B

The R2.8 engine is designed for specific applications. The Plain Washer 3035177 is used in this engine to ensure proper alignment and sealing of various parts, contributing to the engine’s overall efficiency and reliability.

Role of Part 3035177 Plain Washer in Engine Systems

The part 3035177 Plain Washer is integral to the functionality and maintenance of various engine components. It serves as a fundamental element in ensuring the smooth operation and longevity of engine systems. Here’s how it fits into the provided components:

Base Parts

In the assembly of base parts, the Plain Washer provides necessary spacing and alignment between components, ensuring that parts are correctly positioned and operate efficiently.

Brake System

Within the brake system, the Plain Washer is used to maintain proper spacing between brake components, which is essential for the consistent application of braking force and the prevention of premature wear.

Engine Components

- Connection Points: The Plain Washer is employed at various connection points within the engine to ensure that bolts and fasteners are properly torqued and aligned, reducing the risk of component misalignment or failure.

- Exhaust Outlet: At the exhaust outlet, the Plain Washer helps in maintaining a secure and leak-free connection, which is vital for efficient exhaust flow and emission control.

- Crankshaft Seal Pilot and Replacer: When installing or replacing crankshaft seals, the Plain Washer ensures that the seal is properly seated and that there is adequate spacing to prevent damage to the crankshaft or seal.

- Cylinder Liner Installer and Replacer: During the installation or replacement of cylinder liners, the Plain Washer assists in achieving the correct spacing and alignment, which is crucial for the cylinder’s structural integrity and performance.

- Display Panel: In the mounting of display panels, the Plain Washer ensures that the panel is securely attached without exerting undue pressure on the panel or its mounting points.

- Engine Repair Stand Kit: The Plain Washer is used in the construction of engine repair stands to provide necessary spacing and stability, ensuring that the stand can support the engine’s weight and facilitate safe repairs.

- Flywheel: When attaching the flywheel, the Plain Washer ensures proper spacing and alignment, which is essential for the flywheel’s balance and the engine’s overall performance.

- Fuel Pump and Housing: In the assembly of fuel pumps and their housings, the Plain Washer ensures that components are correctly spaced, allowing for efficient fuel flow and pump operation.

- Lever and Rocker: For levers and rockers, the Plain Washer provides the necessary spacing to ensure smooth operation and prevent binding or excessive wear.

- Lower Engine Gasket Kit: Within lower engine gasket kits, the Plain Washer is used to maintain proper spacing between engine components, ensuring a secure and leak-free seal.

- Module and Fuel Control: In the installation of modules and fuel control components, the Plain Washer ensures that these sensitive parts are correctly spaced and aligned, which is vital for their accurate operation.

- Pump and Fuel System: Throughout the fuel system, the Plain Washer is used to maintain proper spacing and alignment of components, ensuring efficient fuel delivery and system performance.

- Rocker Lever: For rocker levers, the Plain Washer ensures that there is adequate spacing to allow for smooth and precise operation, which is essential for valve timing and engine performance.

- Support - Front and Rear Engine: In the support structures for the front and rear of the engine, the Plain Washer provides necessary spacing and stability, ensuring that the engine is securely mounted and aligned.

- Tool Certification Kit: Within tool certification kits, the Plain Washer is used to ensure that tools are correctly spaced and aligned, which is important for accurate measurements and certifications.

- Valve Spring Compressor: When using a valve spring compressor, the Plain Washer ensures that the compressor is properly spaced and aligned, facilitating safe and effective valve spring compression and release.

Conclusion

The Cummins 3035177 Plain Washer is a critical component in heavy-duty truck applications, ensuring the stability, efficiency, and longevity of mechanical systems. Its role in load distribution, surface protection, and fastening security makes it indispensable in maintaining the integrity of truck components. Proper installation, regular maintenance, and timely replacement of this washer are essential practices to ensure the continued reliability and performance of heavy-duty vehicles.

-

Mananathan, R. (2022). Automobile Wheel Alignment and Wheel Balancing. SAE International.

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

ElGindy, M., & ElSayegh, Z. (2023). Road and Off-Road Vehicle Dynamics. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.