This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

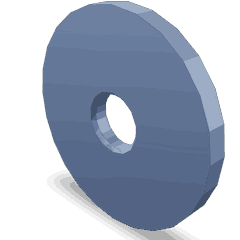

The Cummins 3178457 Plain Washer is a component designed for use in commercial truck operations. It serves a specific function within the mechanical systems of trucks, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and role is fundamental for maintaining and optimizing truck performance.

Basic Concepts of Plain Washers

Plain washers are simple yet vital components in mechanical systems. They are flat, annular metal rings that are placed under bolt heads or nuts. Their primary function is to distribute the load of the fastener more evenly across the surface it is attached to, preventing damage to the material and providing a stable mounting point. Plain washers also help in reducing friction and wear between moving parts, thereby enhancing the longevity and performance of the assembly 1.

Purpose of the Cummins 3178457 Plain Washer

This Cummins part is specifically engineered to play a role in the fastening systems of commercial trucks. It is applied in various truck components where secure and durable fastening is required. By providing a uniform distribution of load, it helps in maintaining the integrity of the fastened components, ensuring they remain securely in place under operational stresses.

Key Features

This Cummins part is characterized by several key features that enhance its functionality. It is typically made from high-quality steel, offering durability and resistance to wear. Its precise dimensions ensure a proper fit within the truck’s fastening systems, while its design allows for efficient load distribution and minimal friction.

Benefits

Using this Cummins part offers several advantages. It improves load distribution across fastened components, which helps in preventing damage and ensuring a secure fit. Additionally, it contributes to the enhanced durability of the fastening system by reducing wear and tear on both the fastener and the surface it is attached to.

Installation Guidelines

Proper installation of this Cummins part is crucial for optimal performance. It should be placed under the bolt head or nut, ensuring it is correctly aligned with the fastener. Tightening should be done gradually to avoid over-tightening, which could lead to damage. Following the manufacturer’s torque specifications is recommended to ensure the washer and fastener operate within their designed parameters.

Troubleshooting and Maintenance

Common issues with plain washers include deformation or wear, which can lead to improper load distribution and fastening failure. Regular inspection for signs of wear or damage is advisable. Maintenance involves ensuring the washer is correctly installed and replacing it if any signs of wear are detected. This proactive approach helps in prolonging the lifespan of the washer and the components it supports.

Compatibility and Usage

This Cummins part is designed for use in specific applications within commercial trucks. It is commonly employed in areas where secure and durable fastening is critical, such as in engine components, chassis parts, and other high-stress areas. Its compatibility with various truck models and components makes it a versatile choice for maintenance and repair professionals.

Safety Considerations

When handling and installing this Cummins part, it is important to observe safety practices to prevent accidents and ensure proper function. This includes using the correct tools for installation, wearing appropriate personal protective equipment, and following all safety guidelines provided by the manufacturer. Proper handling and installation not only ensure the washer’s effectiveness but also contribute to the safety of the personnel involved.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and history of excellence make it a trusted name among professionals in the automotive and heavy-duty truck sectors.

Cummins Part 3178457 Plain Washer Compatibility

This Cummins part is a versatile component designed to fit a range of engine models. This washer is engineered to ensure a secure and reliable seal in various engine applications, providing essential support and stability.

GTA38 G CMEICS G116C

The Plain Washer 3178457 is compatible with the GTA38 G CMEICS G116C engine. It plays a role in maintaining the integrity of the engine’s sealing and fastening systems.

K38, K50, KTA38GC CM558, QSK38 CM2150 MCRS, QSK38 CM850 MCRS

This washer is also suitable for the K38, K50, and KTA38GC CM558 engines. Additionally, it fits the QSK38 CM2150 MCRS and QSK38 CM850 MCRS models. Its design ensures it can handle the specific demands of these engines, providing a dependable seal and support.

QSK50 CM2150 K107, QSK50 CM2150 MCRS, QSK50 CM2350 K108

The Plain Washer 3178457 is also compatible with the QSK50 CM2150 K107, QSK50 CM2150 MCRS, and QSK50 CM2350 K108 engines. It is engineered to meet the rigorous requirements of these engines, ensuring optimal performance and longevity.

Role of Part 3178457 Plain Washer in Engine Systems

In the intricate assembly of engine systems, this part assumes a significant role by ensuring the proper functioning and longevity of various components. This unassuming yet vital component is integral to the assembly and operation of several key engine parts.

Integration with Base Parts and Blocks

The Plain Washer is often utilized in conjunction with base parts and blocks to provide necessary spacing and alignment. When installed in the base of an engine block or cylinder block, it helps in maintaining the correct distance between moving parts, thereby reducing friction and wear. In a cylinder block kit or a service block kit, the washer ensures that components are correctly spaced, which is essential for the efficient operation of the engine.

Application in Cylinder and Short Block Assemblies

In cylinder and short block assemblies, the Plain Washer is employed to secure and align components such as the cylinder block and the cam idler mounting gear. Its role is to provide a smooth surface that minimizes friction between rotating and stationary parts, enhancing the overall performance and durability of the engine.

Use in Hardware and Main Bearings

Within hardware kits and main bearings, the Plain Washer acts as a buffer, distributing loads evenly across the bearing surfaces. This even distribution is vital for the longevity of the main bearings, which are subject to significant stress during engine operation. By reducing direct metal-to-metal contact, the washer helps in preventing premature wear and potential failure of the bearings.

Function in Long Block Assemblies

In long block assemblies, such as the long block assy. - 50, the Plain Washer is crucial for the proper installation and function of various components. It ensures that parts like the EBM-block and water pump idler mounting gear are correctly aligned and spaced, which is essential for the smooth operation of the engine.

Role in Idler Mounting Gear

The Plain Washer is also integral to the idler mounting gear, where it helps in maintaining the correct tension and alignment of the gear. This is particularly important in ensuring that the idler gear operates smoothly and efficiently, contributing to the overall performance of the engine.

Conclusion

In summary, the Cummins 3178457 Plain Washer, though small in size, plays a substantial role in the assembly and operation of various engine components. Its ability to provide necessary spacing, alignment, and friction reduction is essential for the efficient and durable performance of engine systems.

-

Robert Bosch GmbH, Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition, Springer Vieweg, 2007.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.