Minimum Quantity 4

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Lock washers are integral to the maintenance of commercial trucks, ensuring fasteners remain secure under various operating conditions. Among the various types of lock washers available, the S603 Lock Washer by Cummins is notable for its reliability and performance in heavy-duty applications. This document provides an overview of the role and significance of lock washers, with a specific focus on the S603 Lock Washer.

Basic Concepts of Lock Washers

Lock washers are specialized washers designed to prevent the loosening of fasteners due to vibration and torque. They achieve this by applying additional pressure to the fastener, creating friction that helps keep it in place. Lock washers come in various designs, including split lock washers, which have a gap that creates tension when the washer is compressed, and wave lock washers, which have a wavy profile that provides a spring-like action. These washers are commonly used in applications where fastener security is critical, such as in the automotive and heavy-duty truck industries 1.

Purpose of the S603 Lock Washer

The S603 Lock Washer is specifically designed to enhance the security of fasteners in commercial truck applications. It plays a role in maintaining the integrity of various truck components and systems by preventing fastener loosening. This washer is applied in critical areas where vibrations and dynamic loads are common, such as in the engine, transmission, and suspension systems. By ensuring that fasteners remain tight, the S603 Lock Washer contributes to the overall reliability and safety of the truck 2.

Key Features

The S603 Lock Washer is characterized by several key features that enhance its performance and durability in heavy-duty truck environments. Its design includes a split configuration that creates tension when compressed, providing a secure hold on the fastener. The washer is made from high-quality materials, typically spring steel, which offers excellent strength and resilience. Additionally, the S603 Lock Washer may feature a unique coating or treatment to resist corrosion, ensuring longevity in harsh operating conditions 3.

Benefits

Using the S603 Lock Washer offers several benefits in commercial truck maintenance. It improves fastening security by preventing fastener loosening, which can lead to component failure and safety hazards. The enhanced security provided by the S603 Lock Washer reduces the need for frequent maintenance checks and adjustments, saving time and labor costs. Furthermore, by maintaining tight fasteners, the washer contributes to the overall performance and safety of the truck, ensuring that critical components operate as intended.

Troubleshooting and Maintenance

Common issues related to lock washers include corrosion, deformation, and failure to provide adequate tension. To troubleshoot these issues, it is important to inspect the washers regularly for signs of wear or damage. If a lock washer appears corroded or deformed, it should be replaced to ensure continued fastening security. Maintenance practices for the S603 Lock Washer include proper installation techniques, such as using the correct torque specifications for fasteners, and protecting the washer from contaminants that could accelerate corrosion. Regular inspections and timely replacements are key to ensuring the longevity and effectiveness of the S603 Lock Washer in commercial truck applications.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a trusted provider of high-quality components for the commercial truck industry. The company’s expertise in engine and powertrain systems is complemented by its commitment to innovation and customer satisfaction. Cummins components, including the S603 Lock Washer, are designed to meet the demanding requirements of heavy-duty applications, ensuring reliability and performance in various operating conditions.

Cummins Engine Compatibility with S603 Lock Washer

The S603 Lock Washer, manufactured by Cummins, is a crucial component that ensures secure fastening in various engine applications. This part is designed to fit seamlessly with a range of Cummins engines, providing reliable performance and durability.

Engine Compatibility

15N Series:

- 15N CM2380 M104B

4B Series:

- 4B3.9

6B Series:

- 6B5.9

6C Series:

- 6C8.3

G8 Series:

- G8.3

- G855

- G855 CM558

GTA Series:

- GTA38 G CMEICS G116C

- GTA8.3 CM558

- GTA855 CM558 (CM2358) G101

ISX Series:

- ISX CM570

- ISX CM870

K Series:

- K19

- K38

- K50

KTA Series:

- KTA19GC

- KTA19GC CM558

- KTA38GC CM558

N14 Series:

- N14 CELECT

- N14 CELECT PLUS

- N14 G

- N14 MECHANICAL

NH/NT Series:

- NH/NT 855

QSK Series:

- QSG12 CM2880 G112

- QSK19 CM2350 K105

The S603 Lock Washer is engineered to ensure compatibility across these diverse engine models, providing a standardized solution for securing various engine components.

Role of Part S603 Lock Washer in Engine Systems

The S603 Lock Washer is an essential component in ensuring the secure attachment and stability of various engine systems. Its application spans across multiple components, contributing to the overall integrity and performance of the engine.

Barring Mounting Mechanism

In the barring mounting mechanism, the S603 Lock Washer is used to prevent loosening of the fasteners that secure the barring gear. This ensures that the mechanism remains stable during engine startup and operation, preventing any unwanted movement that could lead to damage.

Base Rail and Connection Exhaust Outlet Kit

For the base rail and connection exhaust outlet kit, the S603 Lock Washer plays a role in maintaining the tightness of the connections. This is vital for the structural integrity of the base rail and the secure attachment of the exhaust outlet, ensuring efficient exhaust flow and reducing the risk of leaks.

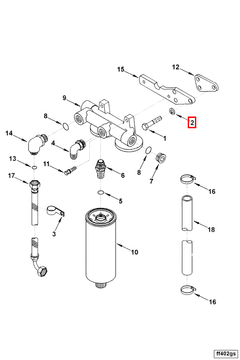

Cooler and Engine Oil System

Within the cooler and engine oil system, the S603 Lock Washer is employed in the fastening of components such as the oil filter housing and cooler mounting brackets. This ensures that these components remain firmly in place, facilitating proper oil circulation and cooling, which is essential for engine longevity.

Cover and Water Header

The cover and water header benefit from the S603 Lock Washer by ensuring that the fasteners holding these components do not loosen over time. This is particularly important for the water header, where secure attachment is necessary to maintain the integrity of the cooling system and prevent coolant leaks.

Crank Flange & Pulley Mounting

In the crank flange and pulley mounting, the S603 Lock Washer is critical for securing the pulley to the crank flange. This ensures that the pulley operates smoothly and efficiently, contributing to the proper functioning of the engine’s accessory drive system.

Cylinder Kit Block and Fan Bracket Mounting Kit

For the cylinder kit block and fan bracket mounting kit, the S603 Lock Washer helps in maintaining the secure attachment of these components. This is important for the structural stability of the cylinder block and the efficient operation of the fan bracket, which is crucial for engine cooling.

Filter and Remote Mount Oil

In the filter and remote mount oil setup, the S603 Lock Washer ensures that the filter housing and oil lines are securely fastened. This is essential for maintaining the efficiency of the filtration process and the integrity of the oil supply system.

Flywheel Housing and Flange

The flywheel housing and flange assembly utilize the S603 Lock Washer to secure the connection between the flywheel and the housing. This ensures that the flywheel operates smoothly and without unnecessary movement, which is vital for the engine’s balance and performance.

Propeller Shaft and Heat Exchanger

In the propeller shaft and heat exchanger, the S603 Lock Washer is used to secure the fasteners that hold these components in place. This is important for the structural integrity of the propeller shaft and the efficient operation of the heat exchanger, ensuring optimal engine performance and cooling.

Hydraulic Pump Mounting and Intercooler Piping

For the hydraulic pump mounting and intercooler piping, the S603 Lock Washer ensures that these components are securely attached. This is crucial for the stable operation of the hydraulic pump and the efficient flow of air through the intercooler, contributing to engine performance and reliability.

Kit Spare (Rad. Cooled) and Lifting Bracket Mounting

In the kit spare (rad. cooled) and lifting bracket mounting, the S603 Lock Washer is used to secure the components, ensuring they remain in place during engine operation and maintenance procedures. This is important for the safety and efficiency of engine handling and cooling.

Oil Gauge Bracket Support and Rear Skid Mounting Support

The oil gauge bracket support and rear skid mounting support benefit from the S603 Lock Washer by ensuring that these components are securely fastened. This is essential for the accurate measurement of oil levels and the structural integrity of the rear skid mounting, contributing to engine maintenance and safety.

Reverse & Reduction and Starting Motor

In the reverse & reduction and starting motor systems, the S603 Lock Washer is used to secure the fasteners that hold these components in place. This ensures that the reverse & reduction gear operates smoothly and that the starting motor is securely mounted, contributing to engine start-up reliability and performance.

Support Rear Engine and Support F E Mounting

For the support rear engine and support F E mounting, the S603 Lock Washer ensures that these components are securely attached. This is important for the structural stability of the engine and the efficient operation of the support systems, contributing to overall engine performance and durability.

Support Fan Bracket and Water Outlet Mounting

In the support fan bracket and water outlet mounting, the S603 Lock Washer is used to secure the fasteners that hold these components in place. This ensures that the fan bracket operates efficiently and that the water outlet is securely mounted, contributing to engine cooling and performance.

Wiring Harness Mounting Kit

Finally, in the wiring harness mounting kit, the S603 Lock Washer ensures that the wiring harness is securely fastened. This is important for the integrity of the electrical connections and the overall reliability of the engine’s electrical system.

Conclusion

The S603 Lock Washer by Cummins is a critical component in the maintenance and reliability of commercial trucks. Its design and features ensure secure fastening in various engine applications, contributing to the overall performance and safety of the vehicle. Regular maintenance and proper installation techniques are essential to maximize the benefits of this Cummins part.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books, 2023.

↩ -

Atkins, Richard D. An Introduction to Engine Testing and Development. SAE International, 2009.

↩ -

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.