This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The S606A Lock Washer is a specialized component manufactured by Cummins, a renowned name in the commercial vehicle industry. This part is designed for use in commercial trucks, where it plays a significant role in maintaining the integrity of bolted connections. Cummins, with its extensive experience and commitment to quality, ensures that the S606A meets the demanding requirements of heavy-duty applications.

Basic Concepts of Lock Washers

Lock washers are mechanical devices used in fastening applications to prevent the loosening of nuts and bolts. They function by applying additional pressure to the components being fastened, which helps to counteract the effects of vibration and dynamic loads. Lock washers come in various designs, including split lock washers and toothed lock washers, each offering unique benefits depending on the application 1.

Purpose of the S606A Lock Washer

The S606A is specifically engineered to enhance the security of bolted connections in commercial trucks. It ensures that fasteners remain tight under dynamic conditions, which are common in heavy-duty truck operations. By preventing loosening, the S606A contributes to the overall safety and reliability of the vehicle, reducing the risk of component failure due to unsecured fasteners 2.

Key Features

The S606A boasts several distinctive characteristics that make it suitable for heavy-duty applications. Its design incorporates a split or toothed configuration, which provides a firm grip on the fastener and the surface it is attached to. The material composition of the S606A is typically high-strength steel, offering excellent durability and resistance to wear. Additionally, its unique attributes, such as a specific thickness and outer diameter, are tailored to meet the rigorous demands of commercial truck environments 3.

Benefits

Utilizing the S606A offers several advantages. It provides improved fastening security, ensuring that bolted connections remain intact even under significant vibration and dynamic loads. Its resistance to vibration is particularly beneficial in the harsh operating environments of commercial trucks, where components are subjected to constant movement and stress. Furthermore, the longevity of the S606A in such conditions ensures that maintenance intervals can be extended, contributing to overall cost efficiency 4.

Installation Guidelines

Proper installation of the S606A is crucial for its optimal performance and durability. It should be placed under the head of the bolt or nut, ensuring that it is correctly aligned with the fastener. Adherence to the correct torque specifications is vital to achieve the desired clamping force without over-tightening, which could lead to damage. Pairing the S606A with appropriate fasteners, as recommended by Cummins, ensures compatibility and effectiveness.

Troubleshooting and Maintenance

Common issues with lock washers include deformation or failure due to excessive torque or corrosion. Regular inspection of the S606A for signs of wear or damage is recommended to identify potential problems early. Should any issues arise, replacing the lock washer with a new S606A model is advised to maintain the integrity of the fastening system. Maintenance tips include keeping the area around the fasteners clean and free from debris, which can contribute to corrosion and premature wear.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and aftermarket parts. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial vehicle industry. The company’s commitment to excellence is evident in its product range, which is designed to meet the demanding requirements of various applications, ensuring optimal performance and durability.

Cummins Lock Washer S606A Compatibility

The Cummins Lock Washer S606A is a critical component designed to ensure secure fastening in various engine applications. This part is engineered to fit seamlessly with a range of Cummins engines, providing reliable performance and durability. Below is a detailed overview of the engines that are compatible with the S606A Lock Washer.

Cummins Diesel Engines

- 4B3.9

- 6B5.9

- 6C8.3

- G855

- G855 CM558

- GTA855 CM558 (CM2358) G101

- K19

- K38

- K50

- KTA19GC

- KTA19GC CM558

- KTA38GC CM558

- N14 CELECT PLUS

- N14 G

- N14 MECHANICAL

- NH/NT 855

- QSK19 CM500

- QSK19 CM850 MCRS

- V28

- V903

- VTA903 CM2250 V105

Application Insights

The S606A is meticulously designed to integrate with the specific fastening requirements of these engines. It ensures that bolts and screws remain tightly secured, preventing loosening due to vibration or thermal expansion. This is particularly important in the demanding environment of engine compartments where reliability and safety are paramount.

Grouping of Compatible Engines

- G Series Engines: G855, G855 CM558, GTA855 CM558 (CM2358) G101

- K Series Engines: K19, K38, K50, KTA19GC, KTA19GC CM558, KTA38GC CM558

- N Series Engines: N14 CELECT PLUS, N14 G, N14 MECHANICAL

- QSK Series Engines: QSK19 CM500, QSK19 CM850 MCRS

- V Series Engines: V28, V903, VTA903 CM2250 V105

- Others: 4B3.9, 6B5.9, 6C8.3, NH/NT 855

Each of these engines, despite their differences in design and application, benefit from the consistent and reliable performance of the S606A. This compatibility underscores Cummins’ commitment to providing high-quality parts that enhance the functionality and longevity of their engines.

Role of Part S606A Lock Washer in Engine Systems

The S606A is an essential component in ensuring the stability and integrity of various engine systems. Its primary function is to prevent loosening of fasteners due to vibration and rotation, thereby maintaining the secure attachment of components.

Air 2-Cylinder Compressor

In the air 2-cylinder compressor, the S606A is used to secure bolts and nuts that hold the compressor to its mounting bracket. This ensures that the compressor remains firmly in place, reducing the risk of misalignment or detachment during operation.

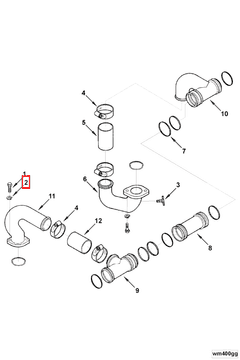

Air Intake Mounting Manifold

For the air intake mounting manifold, the S606A is employed to lock the manifold to the engine block. This prevents any shifting that could affect airflow and engine performance.

Alternator Guard Bracket

The alternator guard bracket utilizes the S606A to secure the bracket to the engine frame. This protects the alternator from physical damage and ensures it remains in the correct position.

Aneroid Mounting Control

In the aneroid mounting control system, the S606A is critical for securing the control unit to its designated location. This maintains the accuracy of the aneroid readings and ensures reliable operation.

B-W Air Compressor Mounting

For the B-W air compressor mounting, the S606A is used to lock the compressor in place. This is vital for consistent air pressure delivery and overall system reliability.

Base Parts Less Rgt

In the assembly of base parts less Rgt, the S606A ensures that all components are tightly secured, preventing any movement that could lead to operational issues.

Block Cylinder Hardware Kit

The block cylinder hardware kit incorporates the S606A to secure bolts and nuts, ensuring that the cylinder block remains stable and aligned.

Corrosion Resistor Head

For the corrosion resistor head, the S606A is used to maintain the integrity of the connections, protecting against environmental factors that could lead to corrosion.

Damper Guard

In the damper guard assembly, the S606A secures the guard to the engine, providing protection against vibrations and ensuring the damper functions correctly.

Filter Head Mounting Lubricating Oil

The filter head mounting for lubricating oil uses the S606A to keep the filter head securely in place, ensuring efficient oil filtration and flow.

Fuel Plumbing

In fuel plumbing systems, the S606A is used to secure fittings and connections, preventing leaks and ensuring a consistent fuel supply.

Fuel Pump & Drive (Wood)

For the fuel pump & drive (wood), the S606A secures the pump to its mounting, ensuring stable operation and reliable fuel delivery.

Fuel Tube

The fuel tube assembly utilizes the S606A to secure connections, preventing fuel leaks and ensuring a steady fuel flow to the engine.

Hand Hole Cover Mounting

In hand hole cover mounting, the S606A ensures that the cover remains securely in place, providing easy access for maintenance while preventing accidental detachment.

Hydraulic Pump Drives

For hydraulic pump drives, the S606A is used to secure the pump to its mounting, ensuring stable and efficient hydraulic system operation.

Kit C L. Parts List

In the kit C L. parts list, the S606A is included to secure various components, ensuring that all parts remain in their designated positions.

Lubricating Oil Pump

The lubricating oil pump assembly uses the S606A to secure the pump to its mounting, ensuring consistent oil circulation and engine lubrication.

Lubricating Oil Suction Tube

For the lubricating oil suction tube, the S606A secures the tube to the pump, preventing any disconnection that could interrupt oil flow.

Rear Water Cross Over Connection

In the rear water cross over connection, the S606A ensures that the connection remains tight, preventing water leaks and maintaining efficient cooling.

Thermostat Housing Mounting Cover

The thermostat housing mounting cover utilizes the S606A to secure the cover, ensuring that the thermostat operates within the correct temperature range.

Torque Converter Cooler Plumbing

For torque converter cooler plumbing, the S606A secures fittings and connections, preventing leaks and ensuring efficient cooling of the torque converter.

Torque Converter Oil Cooler

In the torque converter oil cooler assembly, the S606A is used to secure the cooler to its mounting, ensuring stable and efficient operation.

Water Connection

The water connection system uses the S606A to secure fittings, preventing leaks and ensuring a consistent water flow for engine cooling.

Water Rear Connection

For the water rear connection, the S606A ensures that the connection remains secure, preventing water leaks and maintaining efficient cooling.

Woodward Mounting Governor

In the Woodward mounting governor, the S606A secures the governor to its mounting, ensuring accurate and reliable engine speed control.

Conclusion

The S606A Lock Washer is a critical component in the maintenance and reliability of commercial truck engines. Its design and material composition are tailored to withstand the harsh conditions of heavy-duty applications, ensuring that bolted connections remain secure under dynamic loads and vibrations. Proper installation and regular maintenance of the S606A are essential to maximize its benefits and ensure the longevity and safety of the vehicle.

-

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩ -

Garrett, T. K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

ElGindy, M., & ElSayegh, Z. (2023). Road and Off-Road Vehicle Dynamics. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.